The roasting multifunctional crane is a heavy-duty overhead crane specifically designed for roasting processes in the metallurgy, chemical, and non-ferrous metal industries. It is primarily used for multi-position operations such as feeding, discharging, transferring, and maintaining materials in high-temperature furnaces and kilns.

The roasting multifunctional crane, also called anode baking crane, is a heavy-duty overhead crane specifically designed for roasting processes in the metallurgy, chemical, and non-ferrous metal industries. It is primarily used for multi-position operations such as feeding, discharging, transferring, and maintaining materials in high-temperature furnaces and kilns. The equipment is typically equipped with multiple specialized lifting devices, such as grab buckets, electromagnetic suction cups, or clamps, featuring precise positioning, automated control, and high-temperature operation capabilities, making it suitable for complex and high-intensity operational environments. The multifunctional crane is widely applied in production lines such as aluminum electrolysis, nickel electrolysis, alumina calcination, and lithium battery material production, serving as a critical piece of equipment for achieving efficient material handling and automated roasting processes.

The multifunctional bridge crane moves longitudinally along the factory track via the bridge frame, while the trolley runs horizontally on the bridge frame. The material handling devices (such as suction cups or clamps) mounted on the trolley use a vacuum system or mechanical devices to grasp and release materials. The entire machine is precisely controlled by a PLC control system, combined with variable frequency speed control and sensor technology, to achieve automatic material positioning, handling, loading/unloading, and weighing functions. It is widely applicable for multi-station continuous operations in high-temperature roasting environments.

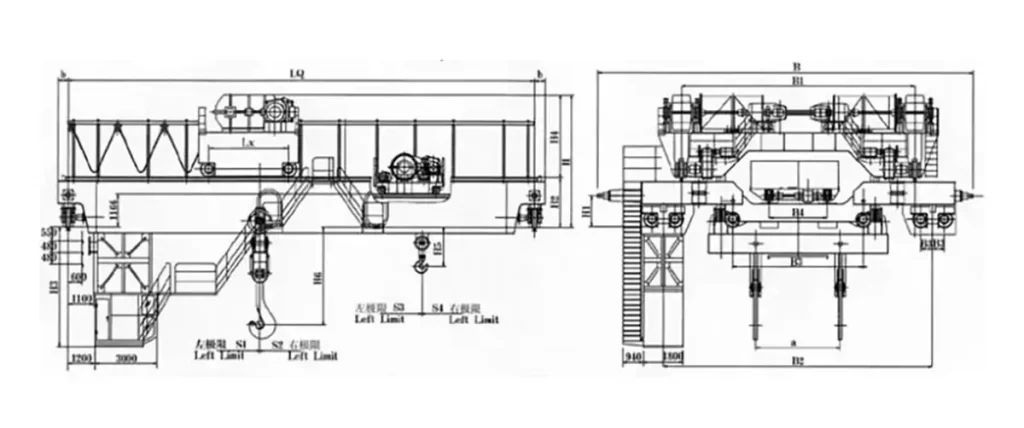

The roasting multi-functional bridge crane mainly consists of components such as the bridge frame, trolley, material suction device (including suction cups, vacuum pump, piping system, and control valves), etc. The overall structure is designed to withstand harsh operating conditions such as high temperatures and dust, ensuring efficient and safe material handling in the carbon industry. Below are the functional features of each component:

Bridge frame: The load-bearing and running structure of the entire machine, featuring high strength and excellent stability to meet heavy-duty and continuous operation requirements.

Trolley system: Equipped with the material handling system, it can operate flexibly along the bridge frame tracks to achieve precise material positioning and handling.

Suction cups/clamps: Customized according to the shape of materials, such as anode carbon blocks, for stable material gripping. Specialized clamps can be used for irregularly shaped materials.

Vacuum Pump: Provides continuous negative pressure for the suction cups. Attention should be paid to its suction force, energy consumption, and operational noise levels to ensure suitability for continuous operation environments.

Piping System: Connects the suction cups to the vacuum pump, maintaining smooth airflow while featuring a flexible design to prevent interference during equipment operation.

Control Valves and Electrical Control System: Enables precise control of component movements, allowing for the adjustment of suction force and the activation/deactivation of the vacuum pump to enhance operational efficiency and safety.

| Baking Multifunctional Crane | Clamps Crane | Vacuum Loading and Unloading Crane | |

| Crane Span (m) | 34.5 | 34.5 | 34.5 |

| Trolley Crane Speed (m/min) | 2-60 | 2-60 | 2-60 |

| Travel Speed (m/min) | 1.6-40 | 1.6-40 | 1.6-40 |

| Clamp | |||

| Lifting Speed (m/min) | 2-10 | 2-10 | — |

| Lifting Travel (m) | 8.5 | 8.5 | — |

| Lifting Weight (t) | Dual Clamps with a capacity of 2×10 | Dual Clamps with a capacity of 2×10 | — |

| Opening (mm) | 5060 | 5060 | — |

| Speed Control | |||

| Trolley crane | Variable Frequency Drive | Variable Frequency Drive | Variable Frequency Drive |

| Trolley | Variable Frequency Drive | Variable Frequency Drive | Variable Frequency Drive |

| Clamp | Variable Frequency Drive | Variable Frequency Drive | — |

| Vacuum Loading and Unloading Pipe | |||

| Lifting Speed (m/min) | 2.6/16 | — | 2.6/16 |

| Lifting Travel (m) | 9.7/9.7 | — | 9.7/9.7 |

| Loading/Unloading Capacity (t/h) | 65/80 | — | 65/80 |

| Material Box Volume (m3) | 45 | — | 45 |

| Vacuum Pump | |||

| Power (kW) | 160 | — | 160 |

| Wind Pressure (kPa) | -40 | — | -40 |

Nucleon is a professional manufacturer and supplier of Roasting Multifunctional Cranes with over 20 years of industry experience, dedicated to providing efficient and safe lifting solutions for high-temperature roasting processes in metallurgy, carbon, and electrolytic aluminum industries. We have a mature technical team and a comprehensive after-sales service system, supporting customized designs for special operating conditions such as high temperatures, dust, and high-frequency operations, including lifting device configurations, control systems, high-temperature resistant structures, and intelligent functional modules. Please provide your process requirements and technical parameters, and we will tailor a professional, multifunctional crane solution specifically for you. Contact us immediately to obtain technical support and a quotation proposal!

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China