Stacker crane achieves high-precision, high-speed and unmanned operation through technologies such as automated control, Internet of Things (IoT) and artificial intelligence (AI), greatly improving storage efficiency and space utilization.

Intelligent warehouse stacker crane (also known as intelligent stacker, automated warehouse stacker) is one of the core equipment of modern intelligent warehousing system. It is mainly for efficient storage, handling and stacking of goods in automated warehouses (AS/RS). Stacker crane achieves high-precision, high-speed and unmanned operation through technologies such as automated control, Internet of Things (IoT) and artificial intelligence (AI), greatly improving storage efficiency and space utilization.

Nucleon, as a professional warehouse stacker crane supplier, provides different types of warehouse stacker cranes, including single-column, double-column, bridge, and multi-deep stacker cranes. The following is a description and application introduction of different types of warehouse stacker cranes.

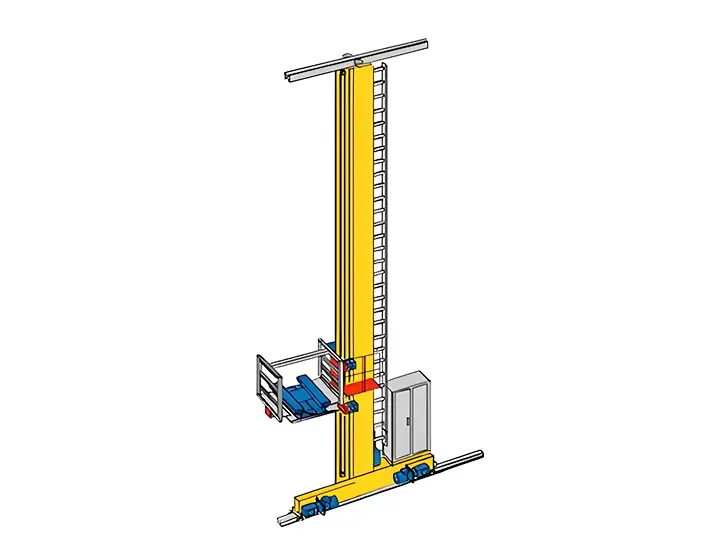

The single-column stacker crane features a single vertical mast that moves along the storage aisles, and forks suspended on one side, and rails laid on the floor. It is usually used for the storage and movement of light goods.

Double Column Stacker Crane With two independent vertical masts, it can handle heavier loads and reach greater heights. This type of stacker crane is commonly employed in warehouses with taller storage structures or when dealing with particularly heavy items.

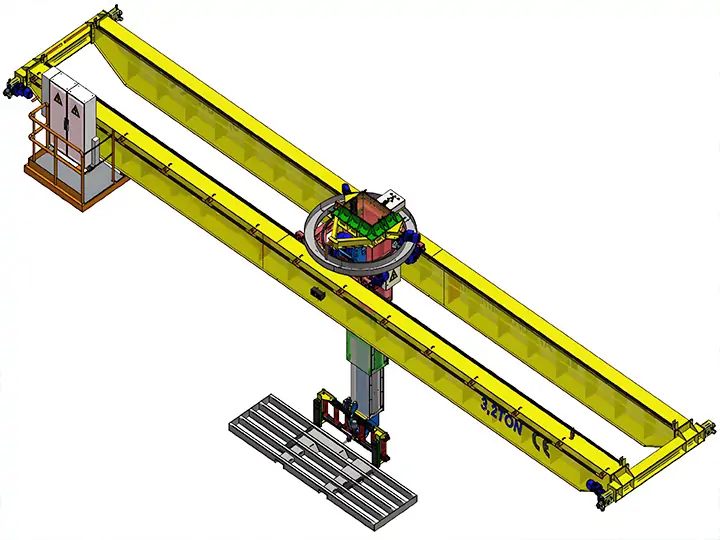

The support rails of the bridge stacker crane are installed on the top of the shelf, and the whole machine is suspended in the air. It can efficiently move and retrieve goods. The bridge stacker crane effectively improves the space utilization rate.

These specialized stacker cranes can reach and retrieve loads from multiple storage positions within a single storage lane. It features a multi-level telescopic arm that traverses the front to access the rear cargo space.

Automation and intelligence: Unmanned operation, automatic storage and retrieval through system instructions. AI predicts inventory demand and optimizes the placement of goods (such as high-frequency goods stored nearby).

High precision and high efficiency: The running speed can reach 4-5 m/s (horizontally) and 1-2 m/s (vertically). Positioning accuracy ±1mm, supporting dense warehousing.

Flexible adaptation: Can handle a variety of carriers such as pallets, bins, cartons, etc. Supports complex scenarios such as narrow aisles (VNA), double-deep positions, and multi-layer shuttles.

IoT integration: Real-time monitoring of equipment status (temperature, vibration, etc.) and predictive maintenance. Linked with AGV, conveyor lines, etc. to form a fully automated logistics chain.

Large manufacturing plants: In large manufacturing plants such as automobile manufacturing and electronic equipment production, intelligent warehouse stacker crane is to store and retrieve raw materials, parts and components, and finished products.

Cold chain logistics centers: Intelligent warehouse stacker cranes can operate efficiently in refrigerated or frozen environments and are used for safe storage and rapid retrieval of temperature-sensitive items such as food and medicine.

E-commerce distribution centers: Intelligent warehouse stacker cranes can quickly and accurately retrieve goods from high-density shelves, supporting efficient order picking and packaging processes.

Airport baggage handling system: Baggage handling systems use intelligent storage stacker cranes to automatically store and retrieve passengers' luggage.

Pharmaceutical warehousing and distribution: An Intelligent warehouse stacker crane can provide precise inventory control and batch management functions to ensure the traceability and safety of drugs throughout the supply chain.

Auto parts storage: Intelligent warehouse stacker crane can classify and store parts according to different specifications and retrieve parts quickly.

| Type | Bridge Stacker Crane |

|---|---|

| Column span | 6-24 m |

| Capacity | 0.5-10 ton |

| Horizontal running speed | 0-100 m/min |

| lifting speed | 5-60 m/min |

| Fork extension speed | 5-20 m/min |

| Power type | Busbar power supply |

| Efficiency | 24-hour continuous operation |

| Space utilization | increased by 50%-80% |

As a well-established manufacturer of warehouse stacker cranes in China, Nucleon Crane can provide customized solutions tailored to your specific needs, including non-standard lifting capacities, lifting heights, lifting/running speeds, and adjustments to control methods.

If you want to know more about warehouse stacker cranes and get a quotation budget, please feel free to consult our technical team.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China