Grab bucket EOT crane is a specialized overhead bridge crane with a grab bucket, ideal for efficiently loading, unloading and transferring bulk materials like coal and minerals. Widely used in ports, mines and more, it saves labor, reduces time and ensures safe, high-productivity operations.

Grab bucket EOT crane is a specialized overhead bridge crane integrated with a grab bucket, designed for efficient loading, unloading, and transferring of bulk and granular materials. Combining advanced crane technology with automated grab mechanisms, it eliminates manual labor, reduces auxiliary time, and ensures safe, high-productivity operations in various industrial scenarios.

As a core equipment in material handling, grab bucket EOT cranes are widely used in ports, docks, mines, metallurgical plants, cement factories, waste treatment centers, and power plants. They excel in handling materials such as coal, minerals, sand, gravel, grain, scrap steel, garbage, and biomass, making them indispensable for bulk material-intensive industries.

Three Phase Induction Motors: EOT cranes widely use three phase induction motors, which provide stable and powerful driving force for the operation of the crane, ensuring smooth lifting, lowering, and movement of the grab bucket.

Grab Mechanism: Composed of grab jaws, connecting rods, and driving devices, it is specially designed to clamp, hold, and release various bulk materials. The jaws are made of high-strength wear-resistant steel to withstand the friction and impact of materials.

Electrical Control System: Includes controllers, contactors, and buttons, which coordinate the operation of motors, hoists, and trolleys. It enables precise control of the crane's speed, direction, and grab action, ensuring safe and efficient work.

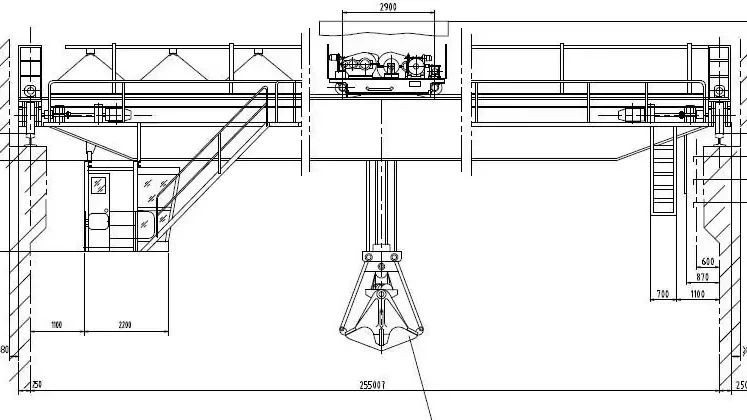

Girders: There are single girder and double girder options. The single girder is a box-type or I-beam structure, lightweight and cost-effective, suitable for medium and small load operations with shorter spans. The double girder, consisting of two parallel main girders, has higher rigidity and load-bearing capacity, making it ideal for heavy-duty operations and longer span working conditions.

We supply a different types of Grab Bucket EOT Cranes designed for efficient bulk material handling, available in different structural forms and grab bucket types to suit various working conditions. Include double-girder, single-girder structures, clamshell grabs, and orange-peel grabs, suitable for handling sand, gravel, coal, minerals, and other bulk materials. Our expert team can provide customized designs tailored to your lifting capacity, span, working environment, and specific operational needs.

Share your project details with us today, and we will create a bespoke Grab Bucket EOT Crane solution that meets your requirements.

Compact in structure, suitable for light to medium-duty operations. Ideal for workshops, small warehouses, or scenarios with limited space. Equipped with clamshell grabs, it efficiently handles loose materials like sand, grain, and fly ash.

Featuring high stability and large load capacity, it is designed for heavy-duty applications. Commonly paired with orange peel grabs or large-capacity clamshell grabs, it is widely used in mines, steel plants, and ports to handle heavy materials such as ore, scrap steel, and large bulk cargo.

Equipped with double-jaw clamshell grabs, it achieves a filling degree of 95-100%, making it perfect for loose granular materials. The cutting edge is reinforced with overlay welding to enhance wear resistance, and multi-layer sealing ensures leak-proof performance, suitable for both land and underwater operations.

Equipped with 4-8 jaw plates, it is designed for irregular materials like scrap steel, waste, and logs. The jaws adjust to material shapes, ensuring secure gripping even for large or bulky items. It is widely used in recycling plants, metallurgical industries, and waste treatment facilities.

| Model | Load Capacity (t) | Grab Volume (m³) | Material Density (t/m³) | Grab Weight (t) | Girder Span (m) |

| Single Girder Clamshell Grab EOT Crane | 2-20 | 1-3 | 0.5-1.8 | 2.1-3.3 | 4.5-28.5 |

| Single Girder Orange Peel Grab EOT Crane | 5-20 | 1-3 | 0.5-1.8 | 2.5-4 | 5-28.5 |

| Double Girder Clamshell Grab EOT Crane | 5-320 | 2-5 | 1.0-2.5 | 3.9-6.4 | 15-30 |

| Double Girder Orange Peel Grab EOT Crane | 5-320 | 4-8 | 1.8-3.0 | 6.5-12 | 7.5-31.5 |

For accurate customization of your Grab Bucket EOT Crane, please provide the following technical specifications so our engineering team can design the most efficient and reliable solution for your needs:

Send us your project details today, and we will provide a tailor-made Grab Bucket EOT Crane solution with professional recommendations.

Nucleon is a professional grab bucket EOT crane manufacturer and supplier. We offer various models of grab EOT cranes, including European standard-type, grab-type, and orange peel-type grab configurations. These cranes are suitable for handling materials such as coal, minerals, and scrap steel, and can enhance production efficiency in high-demand industries such as ports, mining, and metallurgy. With over 20 years of industry experience and a team of professional technicians, we provide customized solutions to meet your specific operational needs. Contact us today to discuss your project and receive a tailored solution and accurate quote.

Grab bucket EOT crane operates by using a bucket that opens and closes to scoop up and release bulk materials. The crane lifts the open bucket, lowers it onto the material, closes the bucket to grab a load, lifts the filled bucket, transports it, and then releases the material at the designated location. This process is typically powered by hydraulic or electric systems that control both the lifting and the opening/closing of the bucket.

A grab bucket is a specialized tool used with cranes for efficiently handling dry bulk materials like sand, coal, and scrap metal. It consists of two or more bucket-like jaws that open and close to scoop up and release materials. This allows for high-volume loading and unloading with minimal manual labor, making it a common tool at ports and industrial sites.

Grab bucket EOT cranes are specifically designed for bulk materials, including ore, grain, coal, sand, gravel, scrap steel, and garbage. Their grab buckets (clamshell or orange peel types) enable efficient opening and closing actions, making them ideal for rapid loading, unloading, and transferring of loose or granular materials in ports, mines, warehouses, and other industrial sites.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China