European double-girder bridge crane is a that adopts advanced European design concepts and manufacturing standards for material handling equipment.

European double-girder bridge crane is a that adopts advanced European design concepts and manufacturing standards for material handling equipment. It is mainly used for warehouses, manufacturing, workshops, precision assembly, etc., in production environments.

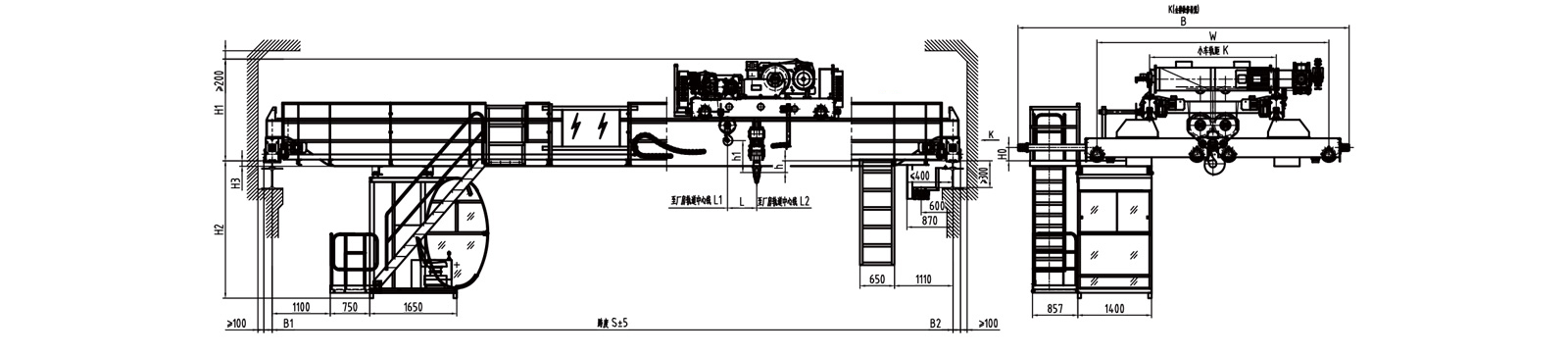

This European-style bridge crane complies with European standards and has the characteristics of compact structure, smooth operation, variable frequency control, and small footprint. It consists of two main beams, end beams, a lifting mechanism, an operating mechanism, and other key components. The hook moves between the main beams to lift or move heavy objects.

Different from traditional overhead cranes, the maximum distance from the hook to the wall is smaller, and lower clearance height. And European bridge crane can be closer to the front for operation, with a higher lifting height. This increases the effective working space of the existing factory building. Due to the lightweight and low wheel pressure, the new factory space can be smaller and more fully functional. A smaller factory means significant savings in initial construction investment, as well as long-term heating, air conditioning, and other maintenance costs.

The European double-beam bridge crane has a wide range of applications.

Compact design: The entire machine is compactly designed, with a three-in-one motor used in the lifting mechanism, which takes up little space, effectively improving the working range and eliminating blind spots in transportation.

Lightweight design: Use high-strength steel to reduce weight, save construction costs, and energy consumption.

Stable operation: Equipped with a frequency conversion control system to achieve millimeter-level precise positioning and zero-impact start and stop, meeting the needs of precision operations.

High reliability: modular design makes subsequent maintenance and overhaul simple and effective in reducing downtime.

Safety protection: The whole machine is equipped with protection devices such as limiters, overload protection, emergency stop buttons, etc., to eliminate the risk of overload and collision.

Economical and practical: Lightweight and frequency conversion technology reduce comprehensive energy consumption by more than 40%, significantly reducing long-term operating costs.

| Lifting Capacity | 5t | 10t | 16/5t | 20/5t | 32/5t | 50/10t | 75/20t | |

| Span | 10.5-31.5 meter | |||||||

| Lifting Height | 12-24 meter | |||||||

| Lifting Speed | Main hook | 0.35-7.6m/min | ||||||

| Aux hook | 0.62-8.8m/min | |||||||

| Trolley Running Speed | 3.2-32m/min | |||||||

| Crane Running Speed | 5-50m/min | |||||||

| Track Recommendation | P38/P43/QU80 | |||||||

| Working duty | A5 | |||||||

| Operating mode | Remote/ Cabin/ Ground control | |||||||

| Power Supply | Customize | |||||||

Nucleon Crane, as a professional manufacturer of European bridge cranes, has 20 years of R&D and manufacturing experience. We provide highly customized solutions including: lifting capacity, lifting height, lifting/running speed, control mode and other parameters. We also provide the following full range of services:

If you want more European double girder bridge crane detailed information or a quotation, please feel free to contact us.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China