NLH double-beam hoist bridge crane adopts lightweight design, energy-saving and high-efficiency, low noise and environmental protection, with a rated lifting weight of 5~32t, suitable for hoisting and handling in workshops, warehouses and power stations.

NLH type double girder hoist bridge crane adopts lightweight, modular and parametric design, combining advanced technology and high efficiency performance to meet modern industrial handling requirements. The hoisting mechanism is equipped with NRT type trolley type electric hoist with excellent performance, and the trolley running mechanism adopts three-in-one driving device with advanced frequency conversion speed control system, which ensures smooth operation and accurate positioning.

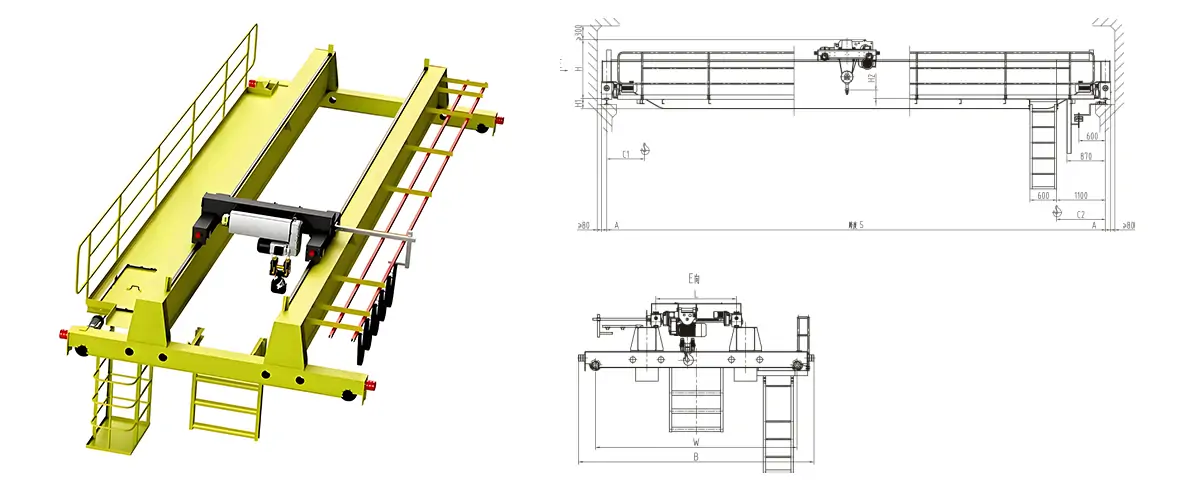

The crane trolley frame adopts ‘H’ shape structure, which is composed of one or two cross beams and two longitudinal beams. For small tonnage cranes, one end of the crossbeam is rigidly connected with the end beam, and the other end is articulated to ensure that the wheels of the trolley can be in close contact with the track under various working conditions, and at the same time, reduce the requirements for manufacturing precision and improve the stability of the structure.

NLH hoist bridge cranes have superior performance, safety and reliability, energy saving, high efficiency and low noise, and environmental protection the remarkable advantages, and are widely used in workshops, warehouses, power stations, and other places for lifting and handling of objects. Its lightweight design not only reduces the cost of plant construction, but also improves space utilisation, providing users with efficient, economical and environmentally friendly lifting solutions.

Lightweight design: NLH double girder hoist bridge crane, according to the new standard, the running unit, bridge steel structure, and accessories are newly designed, with a light structure, beautiful appearance, safety, and reliability.

Convenient maintenance: The double-sided walkway design makes it convenient for personnel to reach all parts of the equipment, making maintenance and repair more efficient.

Precise control: The lifting unit is driven by a two-speed motor to meet the demand for speed regulation, the running unit is equipped with a stepless frequency conversion speed control system, which provides smooth start-up, precise positioning, and small lifting swing.

Stable operation: The trolley adopts a flexible, adjustable system to completely solve the problem of ‘three legs’ and ensure the stability of operation.

Anti-swaying technology: The optional self-developed anti-swaying module can effectively reduce the swaying of the lifting weight and improve safety.

Modular manufacturing: The NLH double girder hoist bridge crane for main beam and end beam adopts modular design and production, high manufacturing precision, convenient installation, and stable quality.

Low headroom height: The overall height of the crane is reduced by 30% compared to traditional overhead cranes. Through optimization of the drum diameter, pulley block, and three-in-one drive unit, the utilization of factory space is significantly improved.

Safety protection: Dual safety features of electrical control braking and mechanical braking, equipped with overload limiter and limit switch, real-time load display, and self-checking voltage.

| Capacity (t) | Span (m) | Lift height (m) | Work duty | Lift speed (m/min) | Trolley speed (m/min) | Crane speed (m/min) | Max. wheel load (Kn) |

|---|---|---|---|---|---|---|---|

| 5 | 10.5 | 6 9 12 | A5 | 0.66/4 0.8/5 1.0/6.3 1.3/8 1.6/10 | 2.0~20 3.0~30 | 3.0~30 4.0~40 | 35.8 |

| 13.5 | 38.6 | ||||||

| 16.5 | 42.4 | ||||||

| 19.5 | 45.6 | ||||||

| 22.5 | 50.8 | ||||||

| 25.5 | 57.8 | ||||||

| 28.5 | 64.3 | ||||||

| 31.5 | 69.8 | ||||||

| 10 | 10.5 | 6 9 12 | A5 | 0.66/4 0.8/5 1.0/6.3 1.3/8 | 2.0~20 3.0~30 | 3.0~30 4.0~40 | 60.5 |

| 13.5 | 64.5 | ||||||

| 16.5 | 69 | ||||||

| 19.5 | 76.3 | ||||||

| 22.5 | 80.7 | ||||||

| 25.5 | 85.9 | ||||||

| 28.5 | 92.6 | ||||||

| 31.5 | 100.5 | ||||||

| 16 | 10.5 | 6 9 12 | A5 | 0.53/3.4 0.66/4 0.8/5 | 2.0~20 3.0~30 | 3.0~30 4.0~40 | 93 |

| 13.5 | 99.7 | ||||||

| 16.5 | 106.8 | ||||||

| 19.5 | 114.4 | ||||||

| 22.5 | 120.8 | ||||||

| 25.5 | 128.5 | ||||||

| 28.5 | 136.1 | ||||||

| 31.5 | 144.3 | ||||||

| 20 | 10.5 | 6 9 12 | A5 | 0.53/3.4 0.66/4 1.2/4.95 | 2.0~20 3.0~30 | 3.0~30 4.0~40 | 112 |

| 13.5 | 120 | ||||||

| 16.5 | 127 | ||||||

| 19.5 | 133.4 | ||||||

| 22.5 | 140.2 | ||||||

| 25.5 | 74.6 | ||||||

| 28.5 | 78.5 | ||||||

| 31.5 | 83.4 | ||||||

| 32 | 10.5 | 6 9 12 | A5 | 0.6/2.6 0.8/3.3 0.82~4.9 1.03~6.2 | 2.0~20 3.0~30 | 3.0~30 4.0~40 | 84 |

| 13.5 | 88.6 | ||||||

| 16.5 | 93.2 | ||||||

| 19.5 | 97.7 | ||||||

| 22.5 | 102 | ||||||

| 25.5 | 107.8 | ||||||

| 28.5 | 112.3 | ||||||

| 31.5 | 117.6BLH |

Nucleon Cranes can provide you with tailor-made NLH double girder hoist bridge crane solutions for your factories and workshops. So far, we have sold various types of bridge cranes to more than 70 countries, including Argentina, Kuwait, Bangladesh, Uzbekistan, Kazakhstan, Bolivia, Chile, Qatar, Tanzania, etc. Nucleon Crane will be your ideal choice for material handling.

If you want to know the NLH double girder hoist bridge crane the technical parameters, drawing design, construction plan, quotation budget, etc., please feel free to consult our professional technical team.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China