Double Girder EOT Crane is core equipment for industrial heavy-load material handling. It has stable structure and strong load-bearing capacity make them widely used in heavy machinery plants, metallurgical workshops, ports, and other locations requiring the handling of large or heavy cargo, providing reliable support for high-load, large-volume material handling.

Double-girder EOT cranes are heavy-duty lifting solutions engineered for efficient material handling in factories, workshops, and warehouses. Featuring a dual-main-girder structure, they offer superior strength, stability, and higher lifting capacity compared to single-girder cranes.

Nucleon Crane provides customized EOT crane designs and configurations to meet your specific operational environments, load requirements, and structural dimensions. Contact us for tailored solutions.

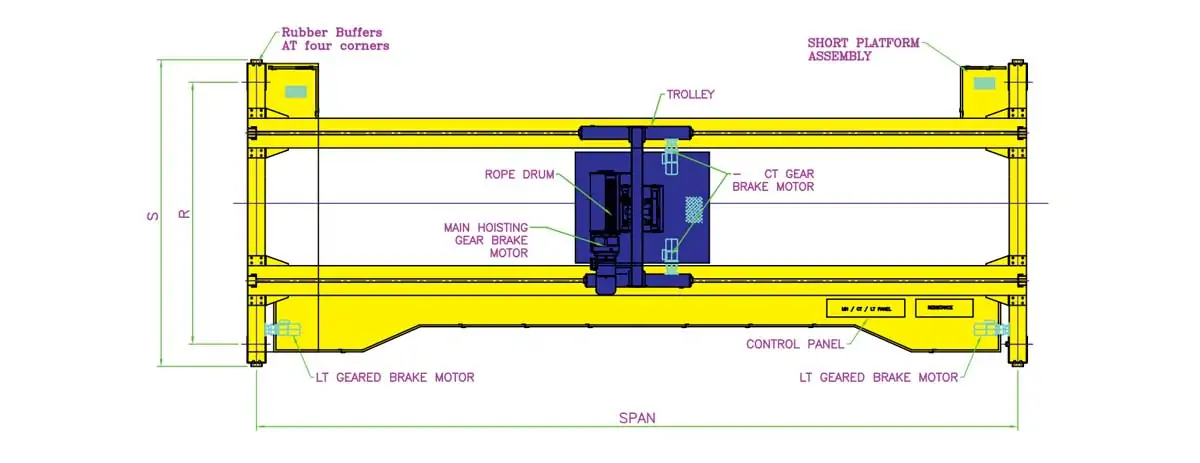

The Double Girder EOT Crane mainly consists of the bridge girders, end carriages, trolley with hoist, runway system, and electrical control components. Below are the functional characteristics of each component:

Double Main Girders: Two box-type or truss-type main girders are arranged in parallel and connected by cross beams, forming a stable load-bearing framework. This configuration offers greater load capacity and span range, enabling coverage of a wider operational area.

End Beams: Mounted at both ends of the main girders, these beams house drive mechanisms that propel the crane longitudinally along the rails, ensuring smooth operation even under heavy loads.

Trolley: Positioned between the two main girders, it comprises a hoisting mechanism, trolley frame, and travel mechanism. It vertically lifts and horizontally moves loads along the main girders, delivering high operational precision and enabling fine positioning.

Electrical Control System: Includes control cabinets, operator handles, or remote controllers, integrated with overload protection and limit switches to ensure safe and reliable operation.

General Purpose Double Girder EOT Crane: Suitable for general material handling in most industrial scenarios, such as steel and equipment components. They can be configured with hooks and slings as needed, offering high versatility and easy operation.

Specialized Double Girder Ladel EOT Cranes: Designed for the high temperature, dusty metallurgical environment, they offer high temperature and corrosion resistance. They are commonly used for specialized operations such as lifting molten steel and handling billets in steel mills. Equipped with specialized high temperature slings and protective systems, they are highly versatile and easy to operate. Explosion proof double girder electric overhead cranes: Utilizing explosion proof motors, electrical components, and a sealed design, they are suitable for hazardous environments where flammable and explosive gases or dust are present, such as chemical plants and oil and gas storage areas, effectively preventing spark induced accidents.

Double Girder Electromagnetic EOT Cranes:Equipped with electromagnetic chucks, these cranes attract magnetic materials like steel and steel plates when powered on and release them upon power failure, eliminating the need for manual lashing. Widely used in steel warehouses, machine shops, and scrap yards, they efficiently handle bulk steel or scrap, minimizing the risk of spillage.

double girder Explosion proof overhead crane: Utilizing explosion-proof motors, electrical components, and a sealed design, all spark-generating components are explosion-proof. They can operate safely in hazardous environments with flammable and explosive gases and dust, effectively preventing explosion risks associated with equipment operation and ensuring stable handling of heavy loads in high-risk environments.

Double Girder Grab Bucket overhead crane: Equipped with a hydraulically or mechanically driven grab mechanism, they automatically grab and unload bulk materials by opening and closing the grab, eliminating the need for manual assistance. Suitable for use in ports, mines, waste treatment plants, and other locations, they can efficiently handle bulk materials such as ore, coal, sand and gravel, and construction waste, significantly improving bulk cargo loading and unloading efficiency and reducing labor costs.

Double Girder EOT Crane is a robust, smooth-running, high-capacity lifting device widely used in factories, warehouses, steel structure manufacturing, and large-scale engineering projects. It offers significant advantages including high efficiency, precision, and safety reliability.

Heavy Machinery Plants: Used for the assembly, handling, and installation of large machine tools and heavy equipment, such as the transshipment of heavy components like steam turbines and rolling mills.

Metallurgical Industry: Used for lifting ladles, billets, and steel products in steel mills and steelmaking plants, withstanding high temperatures and harsh environments.

Ports and Logistics Hubs: Responsible for the loading, unloading, and stacking of containers and large cargo, improving port cargo turnover efficiency.

Energy Industry: Used for the handling of large equipment such as generator sets and boilers in hydropower stations and thermal power plants, supporting the construction and maintenance of power facilities. Bridge and Construction Engineering: Used for the lifting and relocation of bridge components and large prefabricated parts, facilitating the construction of large scale infrastructure projects.

Higher safety redundancy: The double girder structure features an independent dual braking system, and key load-bearing components are designed with multiple safety factors. This effectively reduces the risk of single failures during heavy-load lifting or emergency braking, providing dual safety assurance for high-load operations.

Strong customizability: The modular design of the double girder facilitates compatibility with a variety of specialized lifting equipment. Flexibly integrate explosion-proof and high-temperature resistance features to meet the specific working conditions of different industries, enabling multi-functional heavy-load operations.

Load and Span: Select appropriate parameters based on the maximum load capacity and span of the plant to ensure the equipment's load capacity and coverage meet your needs, while also considering room for future capacity expansion.

Operating Environment: For special environments such as high temperatures, dust, and explosion proof environments, select specialized models with corresponding protection levels. For example, metallurgical models require high temperature resistance or a high temperature resistant coating, and explosion proof models must meet explosion proof standards.

Operating Speed and Accuracy: Select appropriate lifting and operating speeds based on operational efficiency requirements. For high precision operations, prioritize operational smoothness and positioning accuracy.

Safety Configuration: Ensure the equipment is equipped with comprehensive safety devices, such as overload limiters, height limiters, travel limiters, and emergency stop buttons. Intelligent safety features such as video monitoring and remote diagnostics can be added as necessary.

Double Girder EOT Cranes represent one of Nucleon Crane's core products, engineered for heavy-duty lifting and precision material handling. As a trusted manufacturer and supplier with over 20 years of industry expertise, Nucleon focuses on single-girder and double-girder crane solutions, offering a comprehensive product range including general-purpose, metallurgical, explosion-proof, and electromagnetic types.

We deliver customized lifting solutions tailored to diverse operating conditions, suitable for specialized environments, including high-temperature metallurgical workshops, hazardous explosion-proof zones, precision assembly lines, and bulk material handling in warehouses and ports. Our engineering team optimizes each crane's load capacity, span, lifting height, and control system based on your specific application requirements.

Contact us today to receive a customized double-girder EOT crane solution and professional model selection support, which will comprehensively enhance your lifting efficiency and safety assurance.

An EOT (Electric Overhead Traveling) crane mainly consists of the bridge, end trucks, hoist, trolley, and electrical control system.

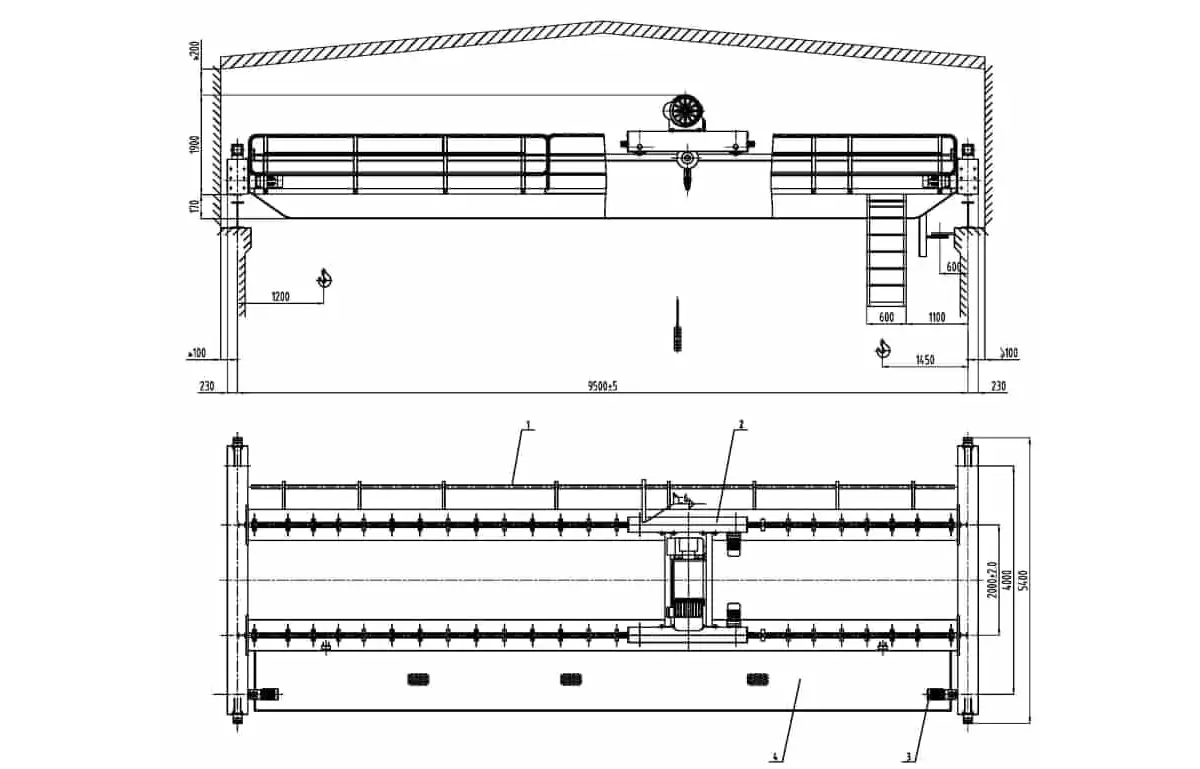

The EOT Crane primarily consists of the bridge girder, main trolley travel mechanism, trolley, and electrical system. The equipment is typically transported to the site in component form and must be installed and commissioned by qualified technicians to ensure safe and stable operation.

Pre-Installation Inspection

Upon arrival at the site, verify all components and technical documentation against the packing list. Inspect the bridge girder for any damage or deformation sustained during transportation. If installation is delayed, place the bridge girder on leveled timber blocks and cover it with protective sheeting to prevent settling or deformation.

1. Bridge Girder Assembly

Connect both end beams into a single unit using bolts. After assembly, ensure the following tolerances are met:

2. Trolley Installation

Place the trolley on the bridge rail, ensuring full contact between the drive wheels and the rail. The gap between idler wheels shall be ≤1mm, with the total length of gap sections not exceeding 2m.

3. Control Cab Installation

Install the control cab, cable retainers, and conductor rails according to the dimensional requirements specified in the drawings, ensuring standardized and safe circuit layout.

4. Wire Rope Winding

Wind the wire rope according to drawings, ensuring it correctly passes over moving and fixed pulleys and is secured at both ends of the drum. When the hoisting mechanism is lowered to its lower limit position, at least three turns of wire rope must remain on the drum.

Safety Notice

Installation and commissioning of electric double-girder overhead cranes must be performed by qualified personnel to ensure long-term safe operation and prevent accidents. For the maintenance guide of the EOT Crane, please refer to this article: EOT Crane Maintenance Guide

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China