Introduction to Gantry Crane

Gantry cranes are essential tools in material handling, offering strength and precision to meet diverse industrial needs. The 5-ton gantry crane from Nucleon Crane (Xinxiang) Co., Ltd. is particularly notable for its load capacity and adaptability. This article offers a comprehensive overview of the 5-ton gantry crane, covering its definition, importance, features, advantages, solutions, types, production parameters, price, applications, and case studies. A parameter table is included for further clarity.

Definition

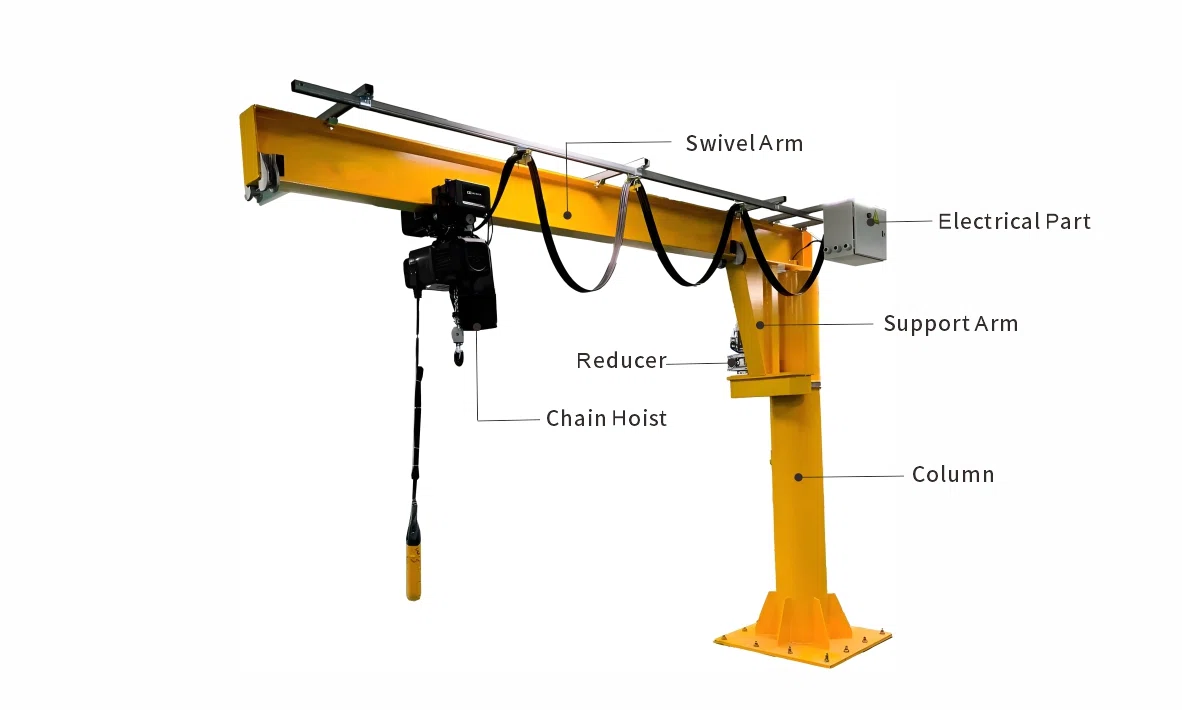

A gantry crane, also known as a goliath crane, is a specialized bridge crane with a horizontal bridge supported by two legs, forming a gantry-like structure. This gantry crane operates efficiently on ground tracks or fixed paths, making it ideal for lifting and moving heavy loads in open spaces like yards, shipyards, and construction sites. The 5-ton model, in particular, has an impressive lifting capacity of up to 5 metric tons, making it suitable for a wide range of applications. It features a portal frame and a hoist that can travel along the gantry beam, and unlike traditional overhead cranes. It is supported by freestanding structures rather than a fixed overhead structure.

Common Problems and Solutions Offered by Nucleon

Common Challenges in Closed Spaces, like Small Workshops and Manufacturing Factories

- Practical Factors: Limited floor space in closed spaces hampers free movement, complicating the handling of large or heavy objects and risking inefficiencies and safety hazards. Moreover, space constraints complicate the optimal arrangement of machinery and equipment, potentially impacting workflow and accessibility.

- Safety Concerns: Busy periods can lead to overcrowding, complicating safe and efficient movement and increasing accident risks. Confined spaces can cause unexpected interactions between equipment, tools, and machinery. It may largely lead to accidents or damage.

- Cost Spending: Small workshops must carefully evaluate the cost of purchasing and installing equipment like gantry cranes within budget constraints. Ongoing maintenance costs for machinery are a concern, requiring allocation of resources for regular upkeep.

Common Challenges in Open Spaces, like Shipyards and Construction Sites

- External Factors: Open spaces are exposed to the elements, which can disrupt work schedules and damage materials and equipment. Large-scale operations in open spaces require extensive material handling, which can be inefficient and costly without proper equipment and planning. Open spaces are more vulnerable to theft and vandalism, necessitating additional security measures to protect assets and personnel.

- Safety Concerns: Open spaces are susceptible to environmental hazards such as high winds, rain, and extreme temperatures. They can bring risks to workers and equipment. These occasions require careful management. Open spaces often involve vehicle and pedestrian traffic. It needs effective traffic control measures to prevent accidents and ensure smooth operations.

Solutions Offered by Nucleon

To tackle these challenges effectively, customers need to implement creative and customized solutions offered by professional teams. In the next section of this article, we will explore Nucleon’s innovative solutions of 5-ton gantry cranes to address these challenges. These solutions not only optimize the workspace but also enhance safety and cost-effectiveness.

To Closed Spaces:

Small workshop owners often face space management challenges. 5-ton gantry cranes can be an affordable investment because they can optimize the use of space, improve safety and reduce accidents and the physical burden on workers.

- Optimize Workspace Utilization: Specifically tailored to navigate through narrow pathways and tight corners, ensuring seamless operation in confined spaces. Maximizes the use of available space, making even the smallest workshops highly efficient.

- Improve Maneuverability: Equipped with advanced controls that allow for precise movements, making it easy to operate even in the most restricted areas.

- Enhance Safety: Reduces the risk of accidents and physical strain, promoting a safer workplace.

- Improve Cost-Effectiveness: Offers a cost-efficient solution that delivers long-term financial advantage.

Different Types of Gantry Crane

We offer a full range of gantry cranes for sale, widely used in ports, logistics centers, construction sites, and storage facilities. Our customized design services meet customers’ unique needs and implementation environments. Options include crane structures (single beam, double beam, or truss), span and lifting height, outrigger forms (double cantilever, single cantilever, or no cantilever), operating mechanisms (rail-type or tire-type), and additional functions. For challenging environments, we provide windproof, explosion-proof, high-temperature-resistant, and corrosion-resistant designs. They are suitable for port operations, heavy manufacturing, railways, and wind power installation.

Single Girder Gantry Crane

Double Girder Gantry Crane

5-Ton Gantry Crane Specifications

Gantry cranes are meticulously classified based on various critical factors, including lifting capacity, span, and the specific type of operation they are designed for. The 5-ton model, positioned within the medium-capacity category, is ideally suited for a broad range of industrial applications. Below is an informative table that outlines the detailed production parameters for this crane:

| Specification | Parameter |

| Lifting Capacity | 5 tons |

| Span | Varies based on specific requirements, typically ranging from 7.5 to 40 meters |

| Height Under Hook | Adjustable to accommodate different lifting heights, ranging from 6 to 24 meters |

| Operating Speed | Designed for efficient lifting and moving speeds, ranging from 20-40 m/min |

| Working Grade | A3-A5 |

Case Study: 4 Ton 5 Ton Gantry Crane Project in Thailand

In March 2025, a Thailand customer purchased a 5-ton MH-type box gantry crane from our company. The customer needed the gantry cranes to solve the material handling problems in its mold production workshop and wanted the equipment to be used both indoors and outdoors. Nucleon team analyzed and combined with the customer’s needs, recommended the MH type box gantry crane. This 5-ton gantry crane has a strong load carrying capacity, a wide range of uses, stable operation, and long service life. So it is the best choice to meet the lifting needs of the mold workshop. At present, this gantry crane has significantly improved the efficiency and capacity of the mold factory. The customer highly recognizes the quality of our equipment, the professionalism of our team, and the production efficiency, and expresses the expectation of cooperation again.

Conclusion

The 5-ton gantry crane embodies the ongoing evolution of material handling technology. Its design merges efficiency, versatility, and reliability, making it crucial in various industries. It excels in handling different loads precisely, whether in shipyards or manufacturing facilities. As industries evolve, the crane will stay essential, enhancing productivity and innovation.

Nucleon will keep offering innovative and customized material handling solutions for global customers. Please feel free to contact us for more details!