A straddle carrier, also known as a container straddle carrier, is a specialized piece of equipment designed for handling containers in ports, container terminals, logistics yards, and multimodal transport hubs. It can directly straddle and lift containers, enabling rapid movement, stacking, and transshipment operations within ports and yards. Nucleon straddle carriers have become a key solution for modern port and yard operations, featuring efficient stacking, flexible mobility, and high throughput.

This article provides a comprehensive analysis of “What is a Straddle Carrier,” covering its structural components, core advantages, price range, and key selection criteria to help you quickly and clearly understand the equipment's characteristics. Please continue reading below.

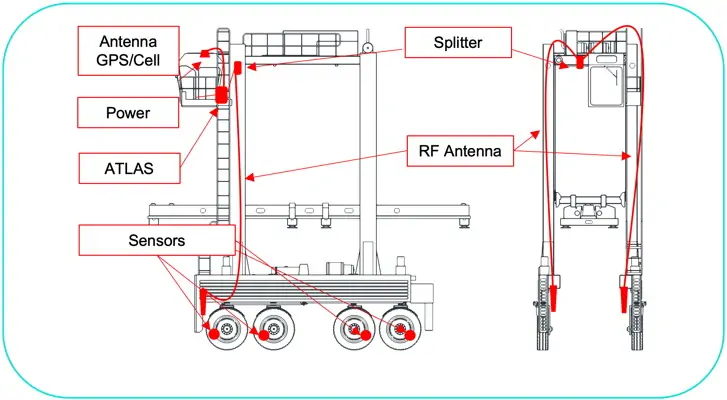

Straddle Carrier Parts

A Straddle Carrier is composed of key parts including the chassis, mast and spreader, engine and transmission, hydraulic system, wheels and steering system, cabin and control system, and essential safety devices.

The following are the features of each part:

Chassis: Supports the entire vehicle structure, with stability and load-bearing capacity.

Mast and Spreader: Used for lifting and clamping containers, enabling precise loading and unloading operations.

Engine and Transmission: Provides power support, has smooth vehicle movement under varying loads.

Hydraulic System: Controls the operation of the mast and spreader, enabling efficient lifting and placement.

Wheels and Steering System: Supports vehicle movement and enables agile operation through precise steering.

Cab and Control System: Provides a visual operating interface for the operator, safe and efficient operation.

Safety Devices: Includes limiters, collision avoidance devices, and alarm systems to ensure safety during operation.

What Is a Straddle Carrier Used For?

A straddle carrier is primarily used for lifting, transporting, and stacking containers within ports, container yards, intermodal terminals, and logistics centers. Its unique straddle-over design allows it to directly pick up containers from the ground without the need for forklifts or cranes, providing high efficiency, flexible maneuverability, and space-saving container handling.

- Port Terminals: Rapidly receive containers after unloading ships and transport them to container yards or transshipment zones, enhancing terminal throughput efficiency and reducing port congestion.

- Container Yards: Stack, reallocate, and transfer containers within the yard; support high-density storage with minimal land requirements.

- Intermodal Terminals: Transfer containers between trains, trucks, and yards; feature short transfer paths, high efficiency, and reduced loading/unloading wait times;

- Industrial & Logistics Facilities: Handling large equipment crates, modular cargo, or specialized containers; Flexible for non-standard cargo handling scenarios;

- Construction Sites & Mobile Projects: Managing project materials, modular equipment, or prefabricated unit transport; Requires no fixed tracks, offers high mobility, and adapts to complex environments.

Straddle Carrier vs Reach Stacker: Which Is Better?

| Feature | Straddle Carrier | Reach Stacker |

|---|---|---|

| Mobility in Tight Yards | ✅ Very Good | Moderate |

| Stacking Height | ✅ Higher (up to 3 containers) | Generally lower |

| Ground Pressure | ✅ Lower (better for yard surfaces) | Higher |

| Fuel/Energy Efficiency | ✅ More efficient long-term | Typically higher consumption |

| Best For | High-volume yards needing fast turnover | Smaller yards with flexible lifting needs |

- Select Straddle Carriers for large yards, port terminals, and continuous 24/7 operations.

- Select Reach Stackers for small and medium logistics centers handling diverse cargo types.

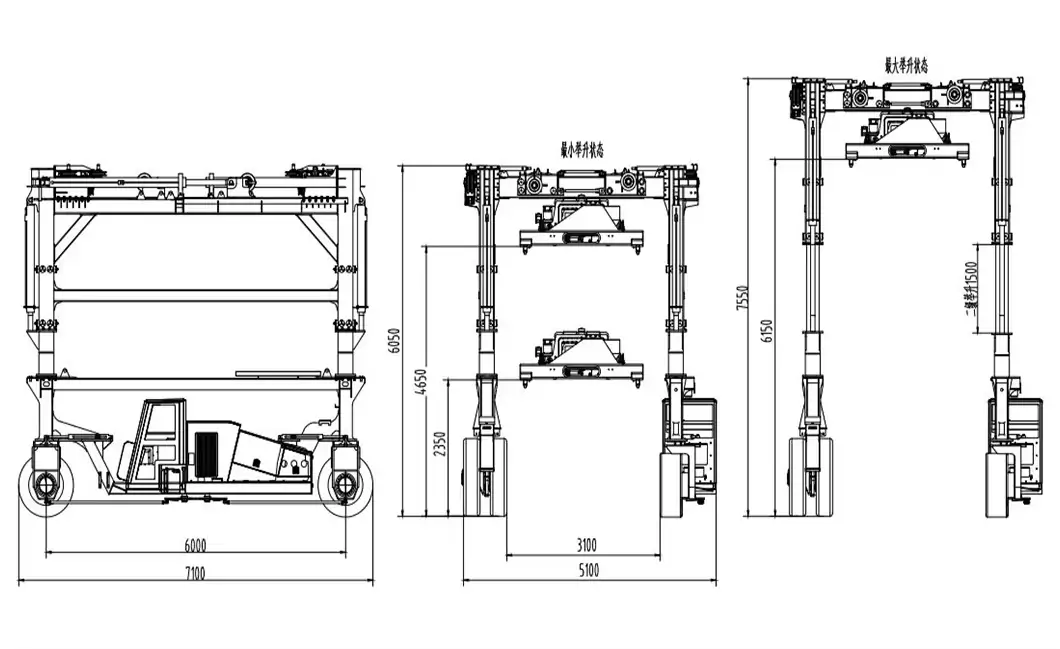

Container Straddle Carrier Specifications

- High lifting capacity: 20–60 tons

- Stacking capability: 1-over-1 / 1-over-2 / 1-over-3

- Power system options: Diesel, Hybrid, or Full Electric

- Precise steering with 4-wheel independent control

- Optional remote control and semi-automation

Nucleon supports full customization according to yard layout, container throughput, and environmental regulations.

Straddle Carrier Diagram

How Much Does a Straddle Carrier Cost?

Straddle carrier price varies based on lifting capacity, stacking height, power system, and automation level.

| Model Type | Capacity | Configuration | Gama de preços (USD) |

|---|---|---|---|

| Standard Diesel Model | 20–40 tons | Manual Operation | $180,000 – $350,000 |

| Hybrid Energy-Saving Model | 30–50 tons | Smart Controls | $260,000 – $520,000 |

| Full Electric Model | 35–60 tons | Low-Emission, Yard Automation | $480,000 – $1,200,000+ |

Tip: The total investment also includes installation, training, and maintenance.

For exact pricing, we provide yard-based configuration assessments.

Are Straddle Carriers Hard to Drive?

Straddle carriers are not difficult to operate for trained personnel. Modern models are equipped with ergonomic cabins, joystick controls, intelligent steering assistance, and camera/monitoring systems, which significantly simplify driving and load-handling tasks. Operators typically sit at an elevated vantage point, allowing for a clear and unobstructed view of the container and travel path, which makes precise alignment and stacking easier.

How to Operate a Straddle Carrier?

- Use the joystick to control the lifting and lowering of containers

- Utilize steering controls for directional movement and tight turning

- Follow visual or camera guidance for container alignment

- Monitor system indicators for load balance, lift height, and travel safety

With standard professional training, most operators can master basic driving and stacking operations within a short period. Advanced safety systems—such as automatic anti-sway, speed limiters, and load monitoring- further reduce operational difficulty and ensure safe, stable handling.

Conclusão

In summary, a Straddle Carrier is a versatile and essential piece of equipment for efficient container handling in ports, terminals, and logistics operations. Its ability to transport heavy loads with precision and speed makes it indispensable for modern supply chains. Whether you are managing a busy shipping yard or optimizing your cargo operations, understanding the benefits and applications of Straddle Carriers can help improve productivity and reduce operational costs. For expert guidance, customized solutions, and support in choosing the right Straddle Carrier for your facility, contact our team today to learn more.