Free standing jib cranes offer flexible operation and efficient material handling capabilities, making them indispensable equipment in numerous applications, including industrial production, warehousing and logistics, and port terminals. Their unique lifting structure enables precise operation within a specific area, meeting material handling requirements in diverse scenarios. This article will provide readers with some basic knowledge about free standing jib cranes to help users use them safely and efficiently.

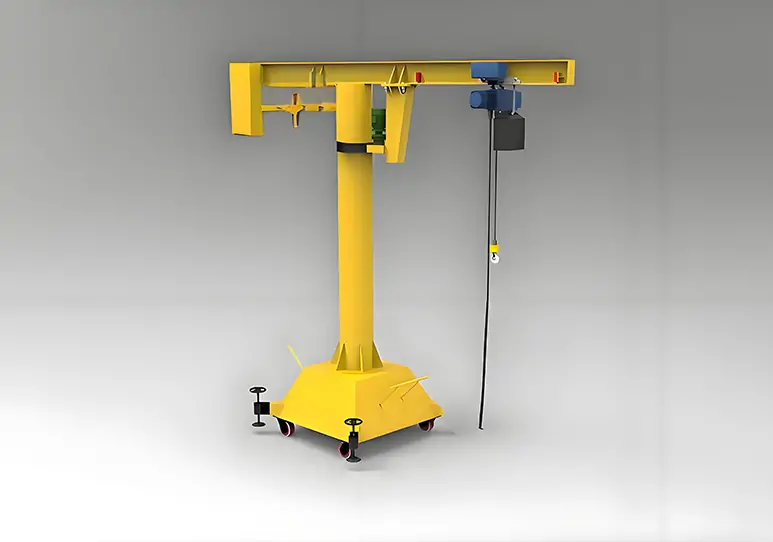

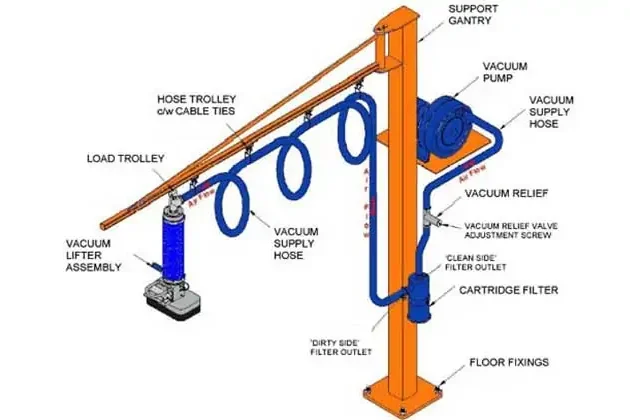

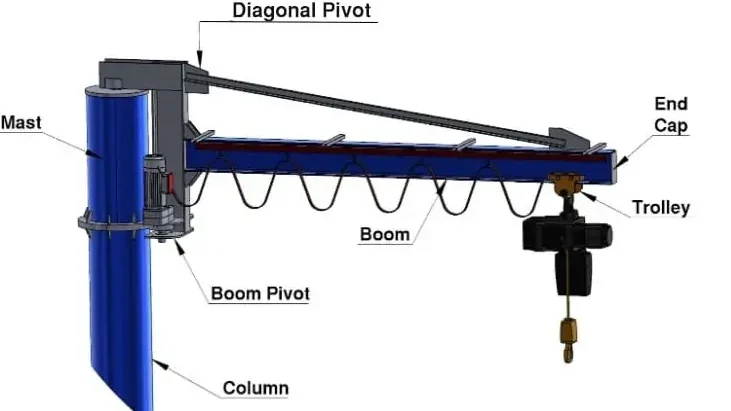

Free Standing Jib Crane Design And Parts

The core structural design of the free standing jib crane features clearly defined components and functions. Each structural module independently performs specific functions while also working together to form a specific functional system. This stable and rational design structure ensures stable, flexible, and safe material handling.

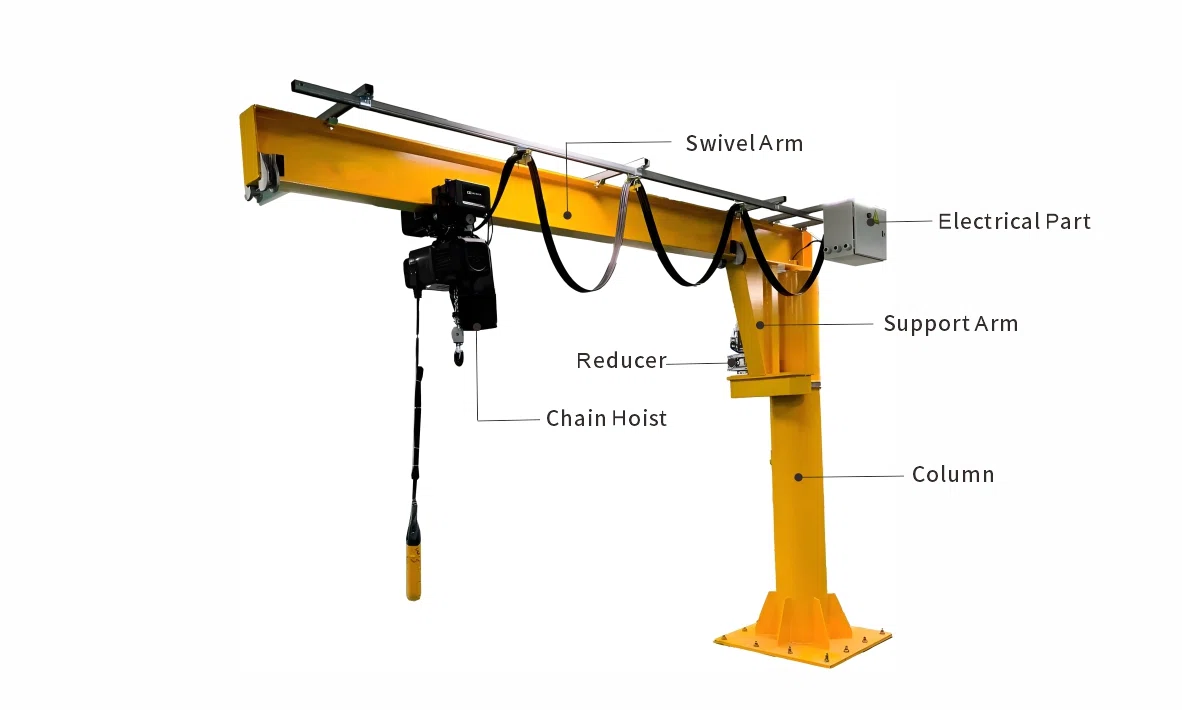

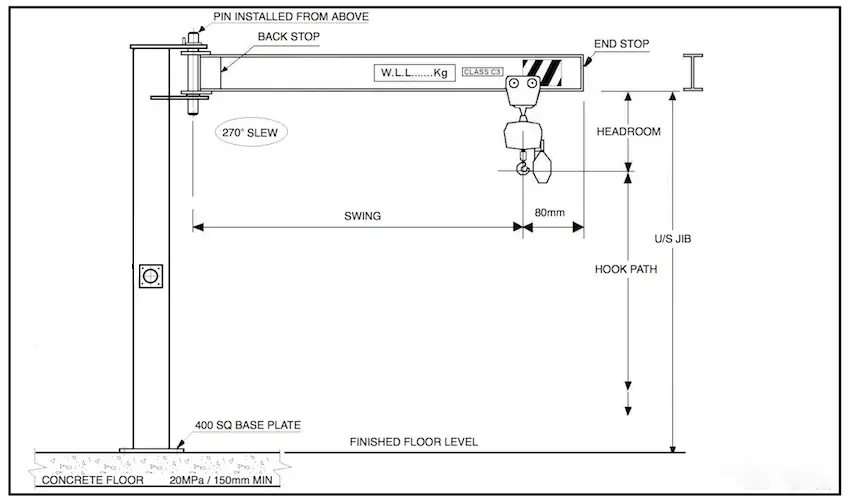

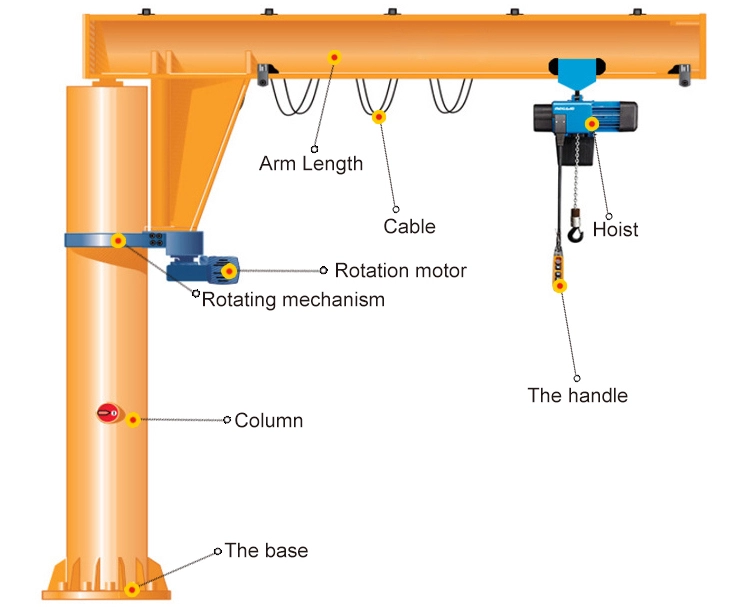

Main support structure

As the foundation for the stable operation of the equipment, it consists of columns and cantilever beams. The columns are firmly connected to the ground, transmitting the weight and load of the equipment while also providing rotational support for the cantilever beams. The cantilever beams provide a running track for the trolley, guiding its horizontal movement. They rotate with the columns to form a circular working area, and some are adjustable in length to accommodate different spaces.

Drive mechanism

It undertakes the task of providing the equipment with operating power and includes a hoisting mechanism and a slewing mechanism. The hoisting mechanism is responsible for lifting and lowering materials, controlling the material's height through power transmission to ensure smooth up and down movement, thus meeting the requirements of loading, unloading, and stacking at different heights. The slewing mechanism, installed at the junction of the column and the cantilever beam, drives the cantilever beam to rotate at multiple angles, breaking the constraints of a fixed operating direction and enabling flexible material transfer within the circular area.

Mobility Auxiliary Structure

Mainly used to expand the equipment's operating range, it consists of a chassis and tracks. The chassis, combined with tires or tracks, provides the equipment with overall mobility, allowing it to travel flexibly on flat surfaces, which makes it ideal for temporary work sites or frequent relocations. The tracks, when combined with the wheel assembly, provide a fixed travel path for the equipment, ensuring stable movement along the track. This feature makes it suitable for long-distance, fixed-route material transfers, such as connecting processes along a production line.

Safety devices

Serving as a crucial component for ensuring the safe operation of free-standing jib cranes, it includes a load limiter, a lift height limiter, and an emergency stop button. The load limiter monitors the load weight, and if overloaded, it triggers an alarm and shuts off power. The lift height limiter controls the lifting limit to prevent damage to the equipment caused by excessive lifting. In an emergency, the emergency stop button can disconnect the main power supply and quickly stop all mechanisms.

Operational Controls

It functions as the device for enabling human-machine interaction and includes both manual and remote control. Manual control integrates multi-action control via a joystick, offering intuitive operation and fast response, which makes it ideal for close-range operations. Remote control utilizes a wireless remote controller that is waterproof, dustproof, and resistant to interference, supporting remote operation. This allows operators to observe operations from a safe distance, enhancing safety and accuracy.

Features And Advantages

High space utilization

The overall structure is compact and does not require too much working space. Especially in space-constrained areas such as workshops and warehouses, it can make full use of vertical and horizontal space to avoid space conflicts between equipment and surrounding facilities.

Strong operational flexibility

It can realize multi-directional material transportation , cover the circular working area centered on the column or the long strip working area along the track, and flexibly respond to material handling needs in different locations.

Convenient and efficient operation

Free standing jib cranes are generally equipped with both manual and remote control modes, allowing operators to choose the appropriate method based on the operating environment . Manual control is responsive and suitable for close-range operations; remote control supports remote operation, allowing operators to observe the entire operation from a safe distance, improving operational accuracy and efficiency.

Reliable safety performance

Equipped with complete safety protection devices, it can monitor the equipment's operating status in real time. When abnormal conditions such as overload and overtravel occur, it can trigger alarms or shutdown protection in time to reduce material falling and the risk of equipment damage.

Low maintenance cost

The structural components do not have complex nesting designs, and the subsequent inspection and maintenance process is simple. There is no need for frequent maintenance by a professional team, which can reduce the company's equipment maintenance costs and extend the service life of the equipment.

Aplicações

The application scenarios of free standing jib cranes cover multiple industries and can be adapted to various scenarios according to different operational requirements:

Industrial production scenarios

Used for material transfer between production line processes within a workshop, such as transferring metal raw materials to machine tool processing stations, transferring processed parts to assembly areas, or transferring finished products from the assembly line to storage warehouses, to achieve continuous connection of the production process.

Warehousing and logistics scenarios

Responsible for the loading, unloading, and stacking of goods in warehouses. They can lift containers and pallets from the ground to high-rise shelves, and can also remove goods from shelves and transfer them to transport vehicles. In logistics parks, they can handle temporary cargo transfer needs, such as short-distance transportation of express parcels and fresh goods.

Construction scenarios

To meet the temporary material handling needs of construction sites, the system can transport steel bars, cement, sand and gravel and other construction materials from the material storage area to the construction floor or work surface, adapting to the material supply needs of different construction stages.

Conclusão

Choosing the right EOT crane is crucial to the efficient operation of any material handling process. Different cranes are suited to different working environments and have unique characteristics. Understanding these factors allows decision-makers to make more informed decisions about which electric overhead crane best suits their needs, ultimately improving workplace efficiency and safety.