Rail mounted container gantry cranes are mainly used for loading and unloading of various containers or railroad wide boxes in container yards such as ports, wharves, railroads and logistics. It can be equipped with various types of container spreaders to meet different lifting needs.

Rail-mounted container gantry cranes (RMG) run on rails using multiple sets of steel wheels and are driven by electric power. They are widely used in container yards or transfer stations in ports, terminals, railroads, and logistics centers, and are capable of efficiently handling and loading and unloading of ISO standard containers as well as railroad-wide containers. The RMGs are featured with multi-functionality, high efficiency, stable operation, ease of operation, and maintenance etc. They are also equipped with comprehensive safety indicators.

Nucleon specializes in providing a wide range of container handling gantry cranes, including top slewing (trolley slewing) and bottom slewing (spreader slewing) designs, with optional cantilevered or non-cantilevered configurations, as well as customized models for railroad scenarios. Our products can be adapted to various general or specialized container spreaders, meeting the lifting needs of standard and non-standard containers in diverse operating environments. This provides customers with flexible and efficient solutions.

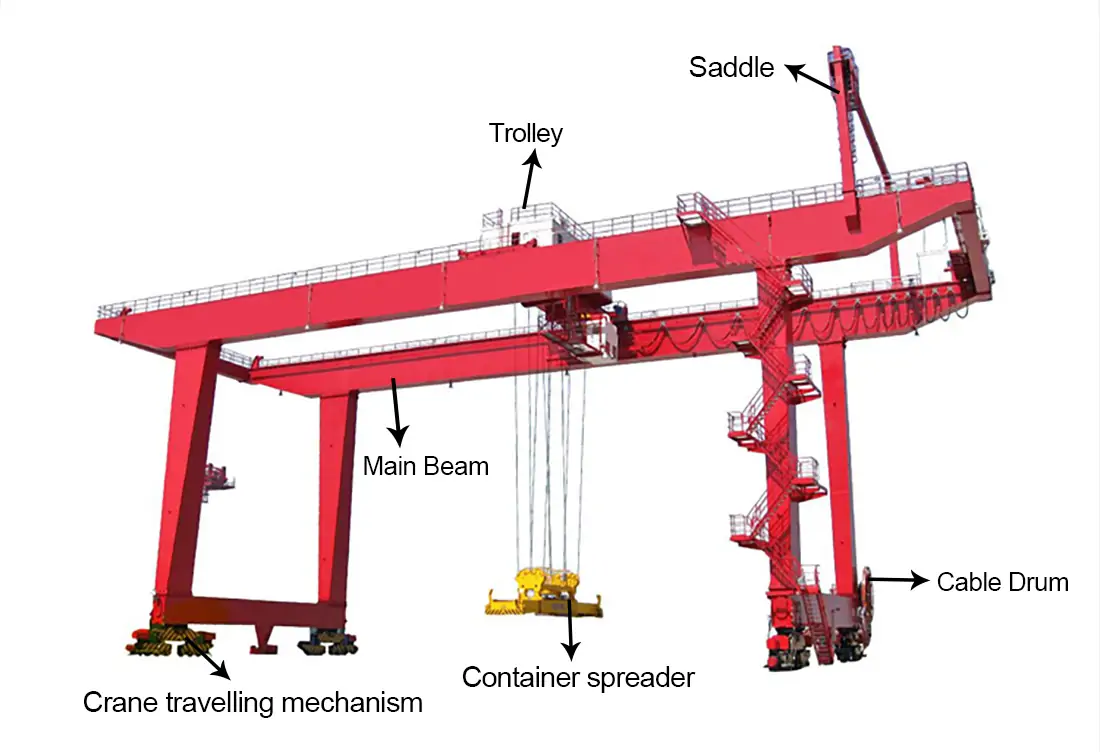

RMG rail-mounted container gantry crane adopts double main girder gantry structure, supported by several steel wheels, and equipped with single trolley winch system (optional mobile driver's room). The entire machine primarily consists of a gantry structure, hoisting mechanism, trolley running mechanism, power supply system, and special container spreader, as well as other components.

| Lifting weight (t) | 10 | 16 | 20 | 10-32 | 36/16 | 10-50 | ||

| Span (m) | 18~35 | 18~30 | 18~35 | 22 | 26 | 22~35 | 35 | |

| Lifting height (m) | Main hook | 11.5 | 10.5,12 | 10.5 | 11.5 | 11.5 | 12 | |

| Auxiliary hook | 11 | 12 | 12 | 13 | ||||

| Speed (m/min) | Main hook | 8.5 | 7.9 | 7.2 | 7.5 | 7.8 | 6 | |

| Auxiliary hook | 10.4 | 10.4 | 10.5 | 10.4 | ||||

| Trolley travel | 43.8 | 44.5 | 44.5 | 41.9 | 41.9 | 38.13 | ||

| Long travel | 37.6,40 | 38,36 | 38,36 | 40 | 40,38 | 38 | ||

| Working Grade | A5 | |||||||

| Power source | Three-phase AC. 127~480V 50/60Hz | |||||||

Nucleon offers tailor-made solutions to meet the different operational needs of a wide range of industries.

Nucleon has over 20 years of manufacturing and project experience, dedicated to providing customers with efficient, reliable, and customized rail-mounted gantry crane solutions. We have a team of experienced professional engineers who are well-versed in the technical details and diverse application requirements of RMG cranes. Whether it's efficient container handling in ports or precise material transportation in manufacturing plants, we can provide tailored designs that precisely meet your needs. Feel free to contact us anytime for customized solutions and quotes.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China