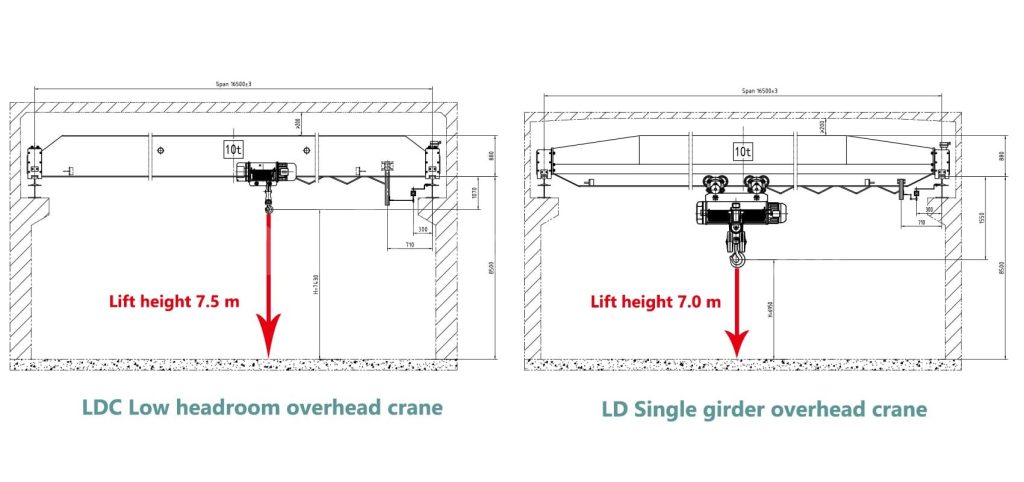

Low-headroom overhead cranes are lifting equipment specifically designed for low-ceiling factories. By highly integrating the hoist trolley with the pulley block, they maximize the effective lifting height achievable within the same factory height.

Low-headroom overhead cranes are an ideal solution for addressing insufficient headroom in factory buildings. Through a unique structural design, they significantly reduce the height of the lifting mechanism, making their overall height approximately 0.3 to 0.5 meters lower than standard single-girder cranes. This advantage directly maximizes the utilization of vertical space in the workshop, effectively increasing storage capacity and improving material handling efficiency without requiring expensive structural modifications. They are particularly suitable for space-constrained factories, workshops, and warehouses, helping users maximize space efficiency in a more economical way.

Nucleon Crane offers various types of low-headroom overhead cranes and customized design solutions to meet your lifting requirements. Contact us today for a tailored lifting solution.

Low-headroom overhead cranes are categorized into two three types based on main girder structure and rail support methods.

The HD type single-girder eot crane adopts an electrified, lightweight, modular, and parametric design. It boasts advantages such as high rigidity, compact structure, and excellent structural design, effectively saving factory space and investment costs.

Product Features

Applications: Suitable for lifting and handling operations in workshops, warehouses, and power plants.

_看图王-768x539.webp)

_看图王-768x539.webp)

The NLX European-style single-girder underhung crane uses I-beams suspended from steel structures or precast roof beams as its running track. This unique design makes it ideal for low-headroom buildings, enabling efficient material handling operations in various industrial environments.

Product Features

Applications: Used for transport and stacking operations in warehouses, logistics centers, and production workshops.

The QDXX type double-girder eot crane is a widely used lifting machine. It mainly consists of two main beams, a hoisting trolley, an operating mechanism, and an electrical control system. Designed specifically for medium to heavy loads and large span applications, its working class is approximately A3 to A7, and its commonly used lifting capacity ranges from 3 to 250 tons.

Product Features

Applications: Suitable for heavy loading, unloading, and lifting operations in factories, warehouses, and freight yards.

_看图王-768x539.webp)

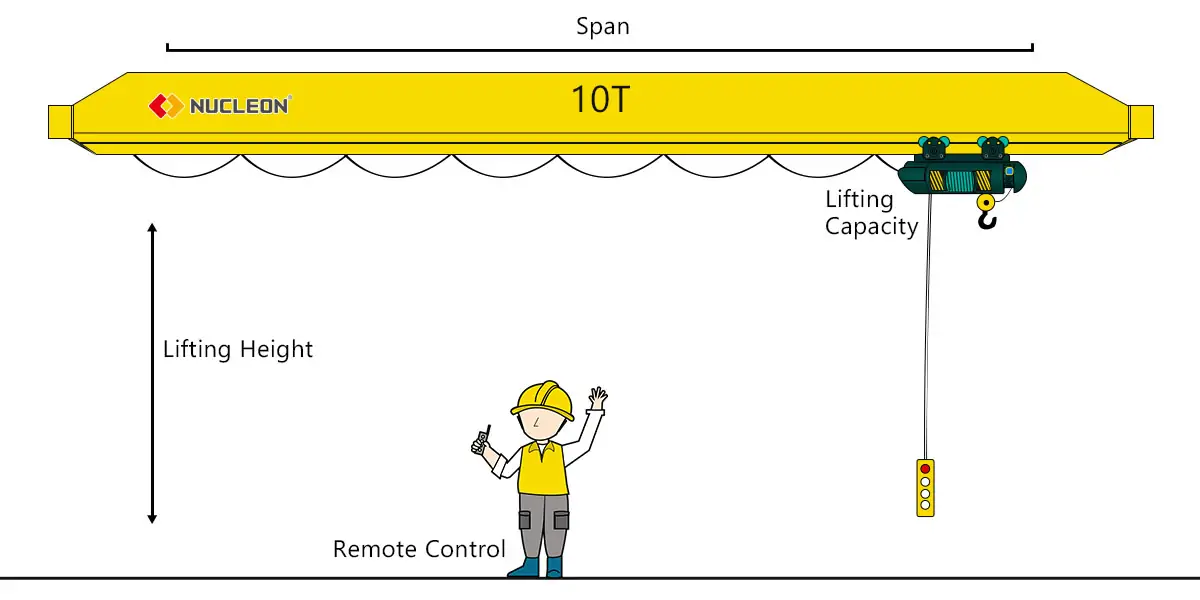

Low-headroom overhead cranes are compact lifting devices that optimize pulley arrangements to enable hooks to operate closer to the ceiling, effectively maximizing vertical space utilization in industrial facilities. Their primary components include:

Simple and Compact Appearance: Maintains a modern architectural style while minimizing space required in the work area.

Easy Maintenance: The relatively simple structure makes maintenance more convenient and quick.

Highly Customizable: Parameters such as span, lifting capacity, and lifting speed can be adjusted according to specific needs to meet the requirements of different application scenarios.

Multiple Safety Measures: Real-time monitoring and overload protection devices automatically alarm and shut down in case of overload.

Space Saving: Suspended directly from the roof beams of the factory/warehouse via end beams, eliminating the need for additional ground tracks or support columns, saving ground space.

Low-headroom overhead cranes are characterized by their compact structure, space-saving design, and moderate load capacity, making them suitable for various industrial scenarios with strict vertical space limitations. Their main application areas include:

Small to medium-sized machining workshops: Lifting small parts or semi-finished products such as gearboxes and shafts; the compact design avoids interfering with ground-based processing equipment.

Electronics and instrument factories: Moving light and precision equipment such as circuit boards and test benches; smooth operation with low vibration protects sensitive electronic components.

Medium-sized logistics warehouses: Loading and unloading small pallets, cartons, and bulk materials; the low headroom design maximizes the preservation of ground storage space.

Equipment repair workshops: Lifting small to medium-sized repair parts such as motor housings and pump bodies; flexible coverage of multiple workstations reduces the risks associated with manual handling.

| Span (m) | 10.5m | 13.5m | 16.5m | 19.5m | 22.5m | 25.5m | 28.5m | 31.5m | |

| Lifting capacity (t) | Main hook | 80 | |||||||

| Auxiliary hook | 20 | ||||||||

| Lifting height (m) | Main hook | 28 | |||||||

| Auxiliary hook | 30 | ||||||||

| Hoisting speed (m/min) | Main hook | 0.15~1.5 | |||||||

| Auxiliary hook | 0.63~6.3 | ||||||||

| Travel speed (m/min) | Crab travelling | 1.5~15 | |||||||

| Crane travelling | 3~30 | ||||||||

| Working class | A3,A4 | ||||||||

| Installed power (KN) | 57.5 | 61.5 | |||||||

| Max. wheel load (KN) | 231 | 245 | 256 | 266 | 269 | 278 | 288 | 296 | |

| Dimensions (mm) | H | 2196 | |||||||

| H1 | 2616 | 2618 | 2718 | 2968 | 2970 | 3170 | 2172 | 3472 | |

| H2 | 196 | 198 | 298 | 548 | 550 | 750 | 852 | 1052 | |

| H3 | 200 | ||||||||

| H4 | 330 | ||||||||

| H5 | 50 | ||||||||

| L | 1080 | ||||||||

| L1 | 956 | ||||||||

| L2 | 2226 | ||||||||

Based on your specific facility layout and operational requirements, we offer professional customization services for low-headroom ovehead cranes, delivering the safest and most efficient space solutions. Please provide details such as your facility's clear height, span, lifting capacity, usage frequency, and duty cycle. We will recommend the most suitable single-girder or double-girder structure along with the optimal hoist configuration. Contact us today for a free quote.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China