Tunnel boring machine lifting gantry crane, also called shield gantry crane is a special lifting equipment specially for tunnel shield construction.

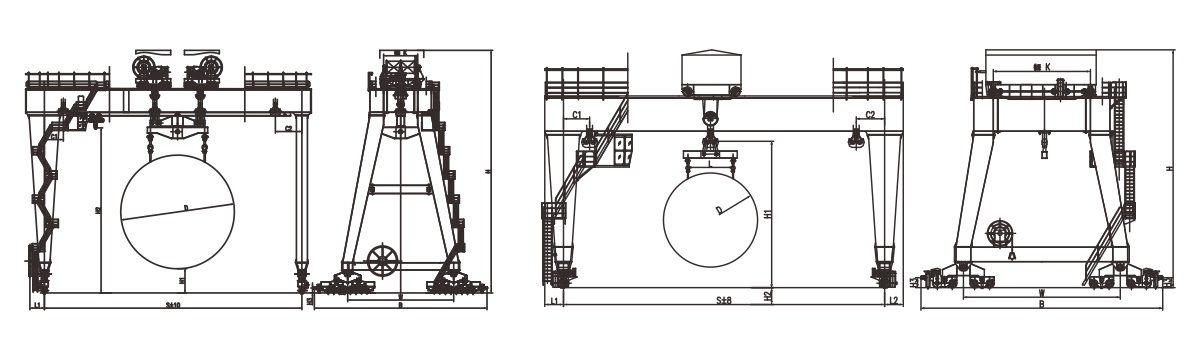

Tunnel boring machine (TBM) lifting gantry crane, also called shield gantry crane and tunnel crane, is specially designed for tunnel shield construction. It is mainly for material lifting and pipe sheet installation in underground projects. The lifting gantry crane adopts a door-type steel structure frame, which has the characteristics of high stability and strong load-bearing capacity. Its main structure consists of rigid legs, main beam, and lifting trolley, which usually move along prepaved tracks. The working mechanism includes lifting, running, and fine-tuning systems, which can achieve precise positioning.

The main functions of lifting gantry crane include the lifting of shield machine components, the transportation and installation of pipe pieces, and the transfer of construction materials. The lifting mechanism adopts frequency conversion control, and operates smoothly and reliably. The span of the gantry can be customized according to the tunnel size, and the common range is 10-34 meters. The rated lifting capacity is generally 50-400 tons.

The advantage of lifting gantry crane is that it adapts to small construction spaces and has flexible and efficient operations. Its low clearance design is particularly suitable for underground engineering environments. The control system can realize manual and semi-automatic operation, and some advanced models have remote monitoring functions. This equipment is widely applied in large-scale underground engineering projects such as subway construction and cross-river tunnels, and is an indispensable key equipment for shield construction.

Ultra-high load capacity and long-span design: Specifically designed for heavy TBM components (cutterhead/shield body, etc.), with a maximum lifting capacity of hundreds of tons. The special long-span structure (up to tens of meters) is tailored to accommodate the spatial constraints of tunnel construction.

Intelligent Precision Lifting System: Equipped with a high-precision control system and anti-swing technology to achieve precise positioning.

Tunnel Adaptability: Modular segmented design facilitates quick assembly and disassembly within tunnels, with dust-proof and moisture-resistant design to withstand harsh tunnel environments.

Multi-layered safety protection system: Overload protection + anti-derailment limit switches provide dual safeguards, along with hydraulic/electric emergency braking systems, etc.

Multi-functional operation configuration: Supports interchangeable lifting tools such as electric hoists/balancing cranes, enabling diverse applications including tunnel segment assembly and equipment maintenance.

Intelligent control options: Optional remote control or automated operation, with intelligent mode switching (suspension/locking, etc.).

| Capacity | T | 100 | ||

| Span | m | 20 | 22 | 24 |

| Lifting height | m | 20 | ||

| Lifting speed | m/min | 0.37-3.7-6 | ||

| Trolley travelling speed | m/min | 0.5-25 | ||

| Crane travelling speed | m/min | 1.4-14 | ||

| Max. Wheel load | KN | 230 | 235 | 240 |

| Rail recommended | Model | QU80 | ||

| Total motor power | kw | 145 | ||

| Main dimension (mm) | Span(m) | 20 | 22 | 24 |

| Crane base distance | W | 10700 | ||

| Crane width | B | 16380 | ||

| Hook left limitation | S1 | 1750 | ||

| Hook right limitation | S2 | 1900 | ||

Nucleon is China's leading manufacturer of lifting gantry cranes, specializing in providing customized gantry crane solutions for you. With extensive global project experience, our products have been successfully deployed in over 30 countries, including Switzerland, Italy, and South Korea, across various industries such as tunnel construction, subway development, and industrial logistics.

We offer a one-stop service system and a professional technical team, capable of providing personalized designs tailored to customer needs, along with comprehensive installation guidance and after-sales service. Whether for standard lifting requirements or special application scenarios, Nucleon can provide you with reliable and efficient solutions. Feel free to contact our professional team at any time to receive customized service support!

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China