Electric winches are professional material handling equipment designed for lifting and traction of heavy objects, and are used in harsh working environments such as construction sites, mines, ports and factories.

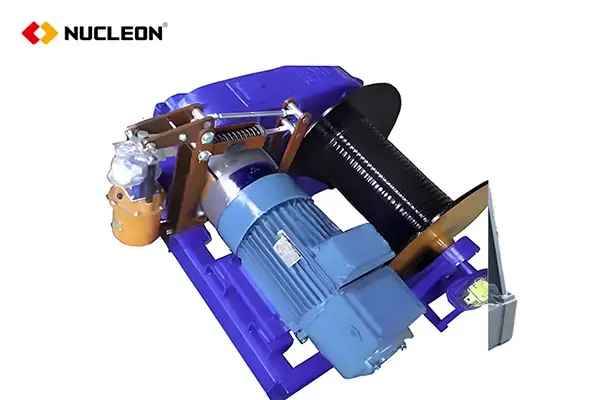

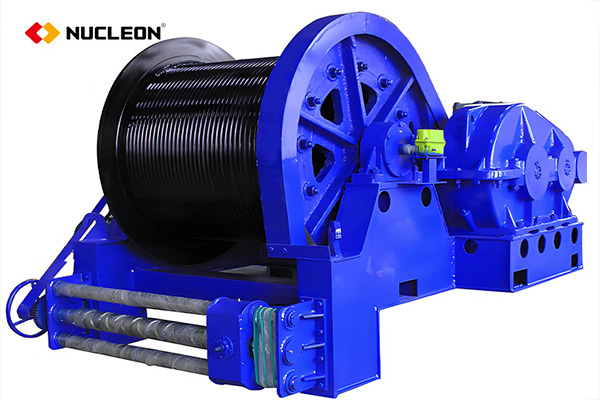

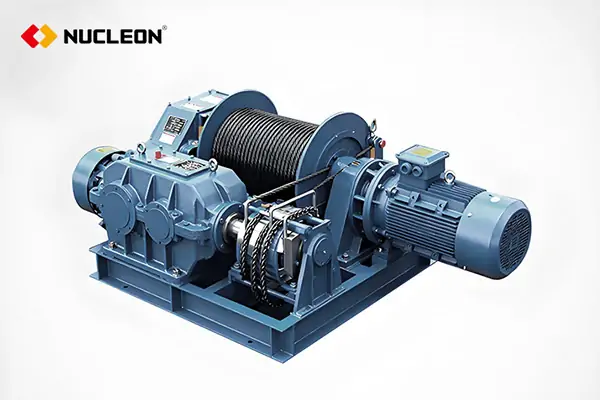

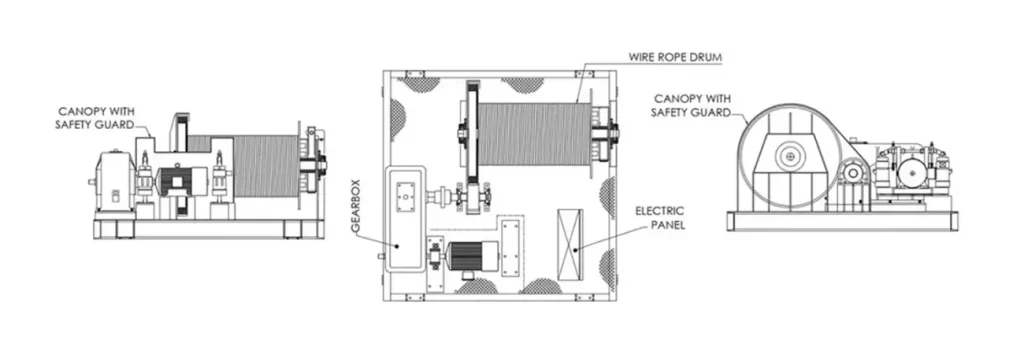

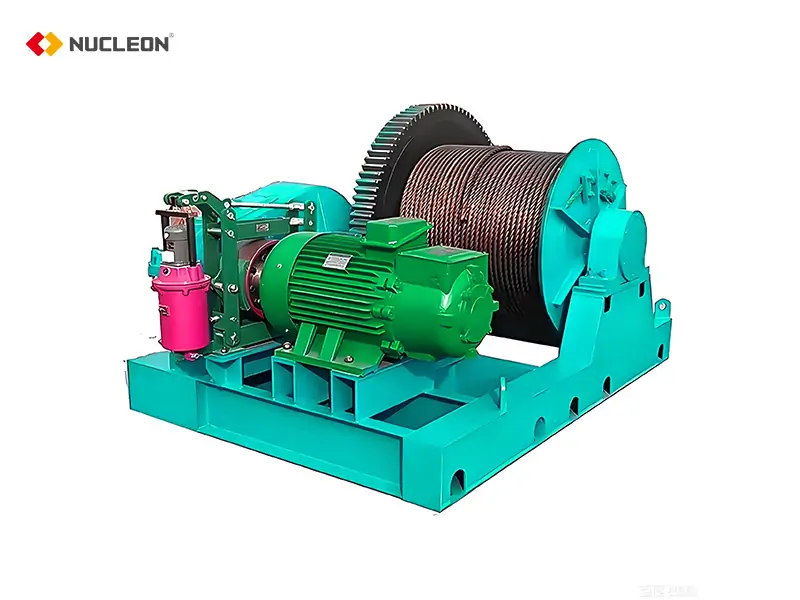

The electric winch machine is a professional-grade heavy-duty material handling equipment suitable for various lifting and traction operations. It utilizes a high-efficiency copper-core motor and a precision reducer to ensure stable torque and smooth operation, adapting to harsh environments such as mines, ports, and factories.

Equipped with both electromagnetic and mechanical braking systems and high-strength steel wire ropes, it provides multiple layers of safety protection. The control panel supports local/remote operation and features speed adjustment and direction switching functions, making it easy to use. With its compact structure, durability, and reliability, the machine effectively improves operational efficiency and reduces operating costs, making it an ideal solution for industrial heavy-duty material handling.

Hydropower Stations: Used for the opening and closing control of heavy-duty gates, the hoisting and maintenance of turbine components, supporting the efficient operation and safe maintenance of the power station.

Mining Transportation Systems: Equipped with hoisting equipment both above and below ground, enabling the safe and efficient transportation of ore, waste rock, and personnel, supporting continuous mining operations.

Construction Sites: Completes the vertical and horizontal transportation of building materials such as steel bars, formwork, and concrete, assisting tower cranes in construction and component installation.

Slipway and Launching Systems: Controls vessels to smoothly enter or exit the water along slipways using winch traction systems, ensuring safe and controllable operations.

Cable and Pipe Laying: Pulls cables, fiber optic cables, and pipes through underground utility tunnels, tunnels, or overhead lines, improving laying efficiency and accuracy.

Forestry and Agricultural Operations: Assists in timber hauling, agricultural machinery hoisting, greenhouse structure construction, and other scenarios, increasing the level of mechanization in operations.

| Category | Main Types | Rated Pull Capacity | Power Parameters | Wire Rope Spec. | Speed Range | Typical Applications | Key Features |

|---|---|---|---|---|---|---|---|

| Drum Config. | Single Drum | 0.5–50 tons | All types | Matched to tonnage | Varies by type | General lifting/pulling | Simple, widely used |

| Double Drum | 3–32 tons | Electric/hydraulic | φ8–40 mm | 10–80 m/min | Dual operations, construction | Simultaneous two-point lifting |

| Category | Main Types | Rated Pull Capacity | Power Parameters | Wire Rope Spec. | Speed Range | Typical Applications | Key Features |

|---|---|---|---|---|---|---|---|

| Speed Type | High-speed | 0.5–16 tons | Mostly electric | φ6–28 mm | 30–150 m/min | Light material handling | High efficiency |

| Low-speed | 5–50 tons | Electric/hydraulic | φ16–65 mm | 1–10 m/min | Heavy installation | High torque | |

| Variable-speed | 3–32 tons | VFD electric / hydraulic | φ10–40 mm | 0–100 m/min | Precision tasks, automation | Smooth adjustable speed |

Note: Specific selection should consult professionals based on actual working conditions. This table is for general reference only.

Nucleon Cranes specializes in providing highly customized material handling solutions to meet diverse customer needs. Our modular design allows for flexible adaptation to various application scenarios.

Rated Lifting Capacity: 0.5–100 tons (customizable)

Span Length: 20–3600 meters

Lifting Speed: 2–40 meters/minute

Power Supply: 220–690V, 50/60 Hz, three-phase power

Product Certifications: CE, ISO, EAC, and other international certifications

Please inform our expert team of your specific working conditions and requirements. We will tailor a material handling solution for you and provide comprehensive professional services.

As a professional supplier of electric winches in China, Nucleon adhere to technology-driven innovation and quality-based core competencies, committed to providing global customers with highly reliable and adaptable lifting solutions.

We possess a complete material handling equipment system, covering a full range of products including electric winches, overhead cranes, gantry cranes, electric hoists, and jib cranes. Leveraging our modular design and customized service capabilities, we can precisely adapt to different scenario requirements, providing professional and efficient technical support and equipment assurance from standardized operations to special working conditions.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China