50 ton gantry crane is a high capacity lifting equipment suitable for both indoor and outdoor operations. They are widely used in construction sites, shipyards, quarries and steel mills.

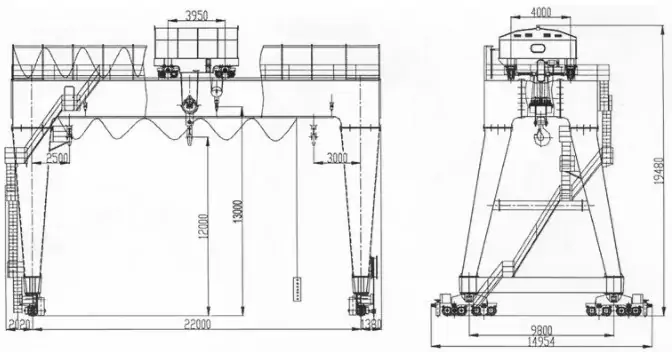

The 50-ton gantry crane is a large-scale, high-efficiency heavy-duty industrial lifting equipment. Its primary structure consists of a “gantry” formed by dual rigid legs and a lifting trolley. The gantry travels longitudinally along ground rails, creating an expansive rectangular working area. It is widely employed in open-air cargo yards, material yards, port terminals, power plants, large-scale equipment manufacturing facilities, and logistics transfer stations for material loading/unloading, transportation, and precise positioning installation.

Nucleon offers various types of 50-ton gantry cranes, customizable to suit different operating environments, cargo types, and production processes to meet diverse operational requirements. Below are several common types and their application scenarios:

Double-girder gantry cranes are the most common cranes used in heavy-duty industrial applications. They feature two parallel horizontal girders, providing greater stability and superior load-bearing capacity, making them suitable for applications requiring large spans and high lifting heights.

Main parameters: The span is usually between 7.5-31.5 meters, and the lifting height is 6-30 meters, which can meet the needs of medium and high-intensity operations.

Applications: Commonly used in manufacturing plants to move large machinery, steel mills to lift steel coils, and quarries to transfer stone. It can also be used to lift heavy smelting equipment and stone raw materials in steel mills and stone processing plants.

Price range: $15,000 to $130,000. The specific price will vary depending on the span, lifting height, and whether customized features such as intelligent control systems and special coatings are required.

Rail-mounted gantry cranes are primarily used for container handling. They operate along fixed tracks and are very stable along planned routes, making them ideal for operations requiring high cargo throughput and high precision.

Main parameters: lifting capacity can reach 25-100 tons, span is 7.5-31.5 meters, power adaptability range is wide, and it is also equipped with an advanced synchronous lifting control system.

Applicable scenarios: Ports, container yards and logistics hubs are its main application places, where it can quickly and repeatedly complete container loading and unloading operations, greatly improving efficiency.

Price range: US$500,000 to US$1,000,000. Costs are relatively high due to the need for complex track facilities and high-precision components.

Rubber-tyred gantry cranes are ideal for applications requiring frequent movement. Equipped with rubber tires, they eliminate the need for fixed tracks and can travel freely on hardened surfaces. They are particularly well-suited for outdoor locations with variable operating paths, such as construction sites and temporary storage areas.

Main parameters: span 20-30 meters, lifting height 12-18 meters, power source can be selected from diesel or electricity to adapt to different outdoor conditions.

Applicable scenarios: Commonly used for stacking containers in ports, moving precast concrete slabs at construction sites, and handling heavy equipment in shipyards.

Price range: $250,000-$500,000. RTG cranes offer a good balance between maneuverability and heavy-load handling capabilities.

The main beam of the truss gantry crane adopts a triangular truss structure, which significantly reduces the weight of the equipment while ensuring strength. Its excellent wind resistance makes it very suitable for outdoor operations. Its lightweight design also reduces installation and maintenance costs.

Main parameters: span 12-35 meters, lifting height 6-18 meters, and stable operation in windy environments such as coastal quarries and open-air construction sites.

Applicable scenarios: Windy working environments such as ports and coastal quarries. It also plays an important role in wind power projects and can be used to lift heavy materials such as stone and wind turbine components.

Price range: $10,000-$100,000. A very cost-effective option for windy conditions.

Solid construction, long-lasting durability

50-ton gantry cranes typically use high-strength steel for their frames, which are sandblasted to remove rust and stress, and then coated with a zinc-rich epoxy coating to prevent corrosion. The high-strength material of the crane itself determines the stability and durability of its lifting capacity.

Multiple safety configurations to reduce risks

The crane will be equipped with various protection measures, including overload protection, emergency stop button, limit switch and anti-sway system, to ensure the safety of technicians and equipment.

Flexible equipment control

Technicians can choose to operate the crane remotely using a wireless remote control device, or perform more precise and specialized operations from within the cab. The most suitable crane operation method can be selected based on needs and construction environment.

Customized adaptation to special needs

50-ton gantry cranes can be customized to meet the diverse needs of various industries by replacing or adding accessories and adding protective coatings. For example, outdoor models can be equipped with waterproof casings, heating control systems, or wind sensors to adapt to rain, snow, and high winds. Specialized accessories such as magnetic chucks, lifting beams, or stone clamps can be added to expand the equipment's functionality. The power supply system can also be adjusted to accommodate specific voltage requirements, meeting the power requirements of different regions or locations.

Custom 50-ton gantry cranes require consideration of operational requirements, environmental conditions, and long-term development plans. The following key factors should be taken into account:

Custom 50-ton gantry cranes require consideration of site space and layout, environmental factors, power supply methods, control systems, structural design, and hook types in addition to the parameters listed above. For tailored solutions and quotations, please contact our professional team.

Nucleon is a manufacturer and supplier of gantry cranes, with 20 years of production and R&D experience and a team of professional engineers. We support customization of various crane types, including single-girder gantry cranes, double-girder gantry cranes, truss gantry cranes, and semi-gantry cranes. If you wish to purchase a 50-ton gantry crane, please contact us for solutions and quotations.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China