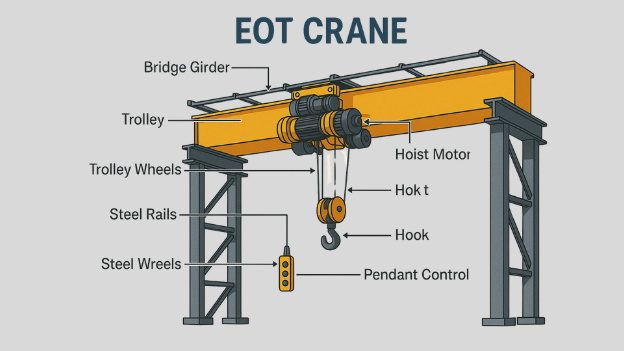

The 5-ton EOT crane is an electric lifting device suitable for factories, warehouses and other places. It uses a large truck, a trolley and a lifting mechanism to lift and transport heavy objects. It has various types and is an important equipment for improving industrial handling efficiency.

The 5 ton EOT crane is an electric lifting device with a rated lifting capacity of 5 tons. It is suitable for factories, warehouses and other places. It uses a large cart, a trolley and a lifting mechanism to achieve the lifting and transport of heavy objects. There are many types of EOT cranes, which are important equipment for improving industrial handling efficiency.

As a core equipment in material handling, grab bucket EOT cranes are widely used in ports, docks, mines, metallurgical plants, cement factories, waste treatment centers, and power plants. They excel in handling materials such as coal, minerals, sand, gravel, grain, scrap steel, garbage, and biomass, making them indispensable for bulk material-intensive industries.

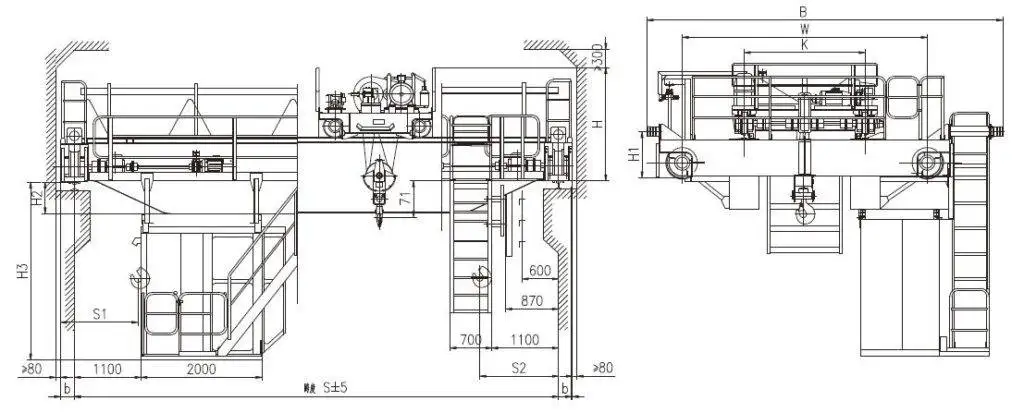

Main beam: The main beam typically adopts a box-type structure. For example, 5-ton EOT cranes also use a non-track box-type main beam, with a truss structure for enhanced wind resistance. Before welding the main beam, the cover and web plates are typically derusted using a roller conveyor and shot blasting machine. During the manufacturing process, U-shaped welded assemblies are used to prevent deformation of the main beam and ensure that indicators such as vertical deflection meet standards.

End beams: Typically adopt a European-style structure, with a series of mature wheel sets. The end beams utilize a center shaft spline drive and a three-in-one drive mechanism, offering advantages such as compact size, light weight, low noise, high efficiency, easy installation, smooth operation, and sensitive braking.

Hoisting mechanism: Consists of an electric motor, brake, reducer, drum, wire rope, and hook. The motor typically uses a conical brake motor, which offers high starting torque and adaptability to frequent starts. The reducer utilizes a multi-stage helical gear transmission. The hoisting mechanism must be equipped with a load limiter and stoppers to ensure safety.

Operating Mechanism: The trolley and trailer operating mechanisms are similar, consisting of a motor, reducer, and roller assembly. A frequency converter can be added for stepless speed regulation, ensuring smooth operation and precise positioning.

Electrical System: Equipped with a phase loss protection device and crane-specific anti-vibration contactors. The electrical control box must be corrosion-resistant and well-planned for easy maintenance. The trolley's mobile power supply system utilizes flat cables, galvanized rails, and cable pulleys to ensure smooth operation.

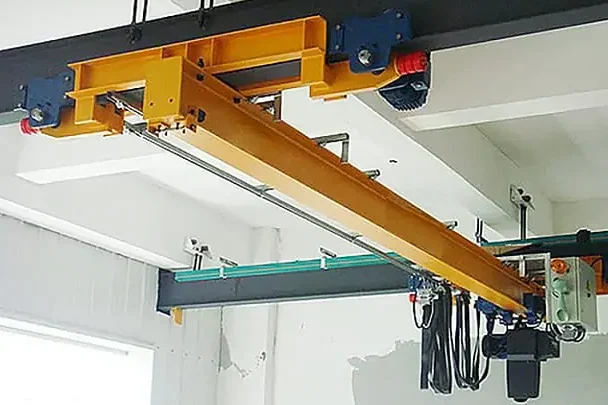

They have a relatively simple structure and are relatively low-cost, suitable for general material handling scenarios with low lifting frequency, small spans, and a 5-ton lifting capacity, such as small machining workshops. Their lifting mechanism is usually equipped with an electric hoist for flexible operation.

A 5-ton EOT crane with a grab bucket beneath its hoist mechanism. The bucket can be opened and closed hydraulically or mechanically, specifically designed for grabbing bulk materials like coal, ore, and grain. It is suitable for loading, unloading, and handling bulk materials in ports, mines, and material yards, significantly improving handling efficiency and reducing manual labor.

Their tracks are typically suspended from the load-bearing structure of the factory ceiling, with the crane body hanging below the tracks. This compact design saves floor and lower factory space, making them suitable for locations with limited height and floor space, such as small workshops and laboratories, to enable flexible material handling in confined spaces.

For accurate customization of your 5 Ton EOT Crane, please provide the following technical specifications so our engineering team can design the most efficient and reliable solution for your needs:

| Parameter name | Parameter range |

| Rated lifting capacity | 5 tons |

| Span range | 7.5 - 28.5 meters |

| Lifting height | 6 - 30 meters |

| Lifting speed | 0.8 - 8m/min |

| Car running speed | 20 - 30m/min |

| Cart running speed | 20 - 30m/min |

| Total motor power | 8.3kw |

| Total weight range | 2220 - 8990kg |

| Maximum wheel pressure | 28.7 - 47.9 kN |

| Recommended track models | 24kg/m |

Send us your project details today, and we will provide a tailor-made 5 Ton EOT Crane solution with professional recommendations.

| Crane type | Price range |

| 5 ton EOT crane | $3,100 - 16,700 |

| Single girder 5 ton crane | $15,500 - 29,000 |

| Double girder 5 ton crane | $15,500 - 29,500 |

| Grab bucket EOT crane | $7,400 - 8,200 |

| Underslung EOT crane | $5,000 |

The above prices are for reference only. The actual prices will be affected by specific configurations, accessories and other factors. If you need an accurate quotation, please contact us and explain your actual needs. We will provide you with a more accurate and affordable price.

5-ton EOT cranes are versatile and suitable for material handling. With over 20 years of experience, Nucleon offers a variety of custom designs, including suspended, grab, and explosion-proof models. Our cranes are sold in over 160 countries. If you require a 5-ton EOT crane, our engineers will provide you with a precise product solution and quote.

The span of a 5-ton EOT crane typically ranges from 7.5 to 28.5 meters, and the space required depends primarily on its span and structure. Vertically, the space required includes the lifting height and the height above the track. Underslung cranes save floor space, but still require overhead clearance. The actual space required will vary depending on the span, lifting height, and installation type.

According to some crane specification guides, the lifting height of a 5-ton EOT crane is generally between 6 meters and 30 meters. The specific height depends on the specific model and configuration of the crane.

Yes, a 5-ton EOT crane can be upgraded to a higher load capacity in the future. If the mechanical, electrical, and structural components of the existing crane can withstand the increased stress, then upgrading the EOT crane to handle the larger load may be more cost-effective than replacing the entire crane system.

Proper maintenance is essential to ensure the safe, efficient, and long-term operation of your 5-ton EOT crane. Below is our guide to key parts maintenance.

All maintenance items must be recorded in detail, including maintenance time, component status and replacement accessory model, to facilitate tracing changes in equipment performance.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China