The 3 ton overhead crane adopts a lightweight structure, is flexible and easy to operate, and is equipped with an electric hoist/trolley, which can run stably on the track and efficiently complete material handling.

A 3 ton overhead crane is a lightweight lifting system designed for handling small to medium loads in workshops, warehouses, and light manufacturing facilities.

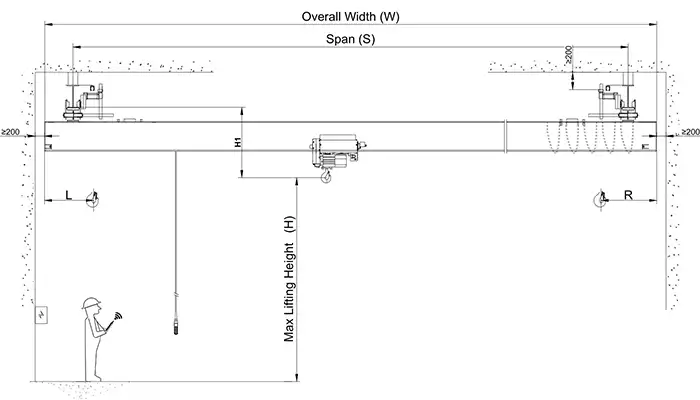

It consists of a stable bridge running along fixed rails, equipped with an electric hoist or trolley, enabling smooth horizontal and vertical material movement.

Different work environments require different lifting solutions. We provide several types of 3 ton overhead cranes to meet diverse needs.

The price of a 3 ton overhead crane depends on several factors, including span, lifting height, power supply, working environment, and special configurations (e.g., explosion-proof, corrosion-resistant, low headroom).

| Types | Capacity (t) | Span (m) | Lifting Height (m) | Power Supply Voltage (V) | Application | Reference Price (USD) |

| 3-ton single-girder overhead crane | 1 - 32 | 7.5 - 28.5 | 6 - 30 | 220V-660V, 50-60Hz, 3ph AC | General material handling in workshops, warehouses, assembly lines, etc. | 2,000 - 7,500 |

| 3 ton low headroom overhead crane | 1 - 32 | 7.5 - 28.5 | 6 - 30 | 220V-660V, 50-60Hz, 3ph AC | Workshops and warehouses with limited factory height | 2,100 - 8,000 |

| 3 ton suspension overhead crane | 0.5 - 10 | 7.5 - 31.5 | 6 - 30 | 220V-660V, 50-60Hz, 3ph AC | Lightweight factories and small warehouses without track support, where lightweight materials are frequently transported | 2,000 - 7,500 |

| 3-ton European standard overhead crane | 1 - 30 | 7.5 - 28.5 | 6 - 12 (customizable) | 220V-660V, 50-60Hz, 3ph AC | Precision processing workshops and automated production lines require high precision and durability | 4,800 - 10,900 |

| 3-ton grab overhead crane | 3 - 50 | 7.5 - 28.5 | 13/16 (customizable) | 220V-660V, 50-60Hz, 3ph AC | Garbage disposal, mines, sand fields and other places where bulk material handling is required | Customized on demand |

| 3 ton explosion-proof overhead crane | 1 - 20 | 7.5 - 28.5 | 6 - 12 (customizable) | 220V-660V, 50-60Hz, 3ph AC | Chemical plants, refineries, gas stations, and other sites where materials in flammable and explosive environments are handled | Customized on demand |

Contact us with your working conditions (span, height, voltage, etc.) for an accurate quote and technical proposal.

The design of a 3-ton overhead bridge crane usually requires the following technical parameters:

Lifting capacity: 0.5~10 tons (3 tons is a common lifting capacity, and the lifting capacity range of this type of crane is generally within this range)

Span: The distance from the center of the track to the center, usually between 3 meters and 16 meters, and some can reach 32 meters. The common range is 7.5 meters to 22.5 meters (depending on different structural designs and application scenarios).

Lifting height: the maximum height of the hook from the ground, generally 6-30 meters, can be customized according to the workshop height and usage requirements (for example, low factories can be adapted to lower specifications, and tall industrial sites support special heightened solutions).

Working level: For example, A3 and A4, with A3 being the most common. A3 is suitable for working scenarios with low frequency of use and relatively infrequent loads; A4 is suitable for working conditions with certain frequency of use and load requirements.

Power supply configuration: The standard power supply is 380V/50Hz/three-phase AC power. Customization is supported based on power supply standards in various regions around the world. Typical optional voltage specifications include 220V and 415V.

Ground-wired button control: adopts a direct operation mode, suitable for fixed working scenarios with stable working conditions and a limited control radius.

Wireless remote control device: Integrates advanced radio frequency technology to support barrier-free control within a range of 150 meters (breaking the limitations of physical cables and significantly improving the mobility of station operations).

Indoor: Generally, a standard design can meet the requirements. However, factors such as the size of the indoor space and the presence of obstacles need to be considered to influence the operation of the overhead crane.

Outdoor: We must consider protective measures like windproof, rainproof, and sunproof solutions—for example, installing windproof anchoring devices and rain covers. This ensures the 3-ton overhead crane operates safely and stably in adverse weather conditions.

Explosion-proof requirements: If used in chemical plants, refineries, or other environments with flammable and explosive media, we must configure electrical systems and structural designs that meet explosion-proof standards. These include, but are not limited to, explosion-proof motors and intrinsically safe control boxes, which help eliminate potential explosion risks caused by electrical sparks.

Anti-corrosion requirements: When used in environments with corrosive media, such as electroplating workshops and coastal areas, professional anti-corrosion processes should be implemented on the overhead crane's metal components and parts. This includes using corrosion-resistant alloy materials such as stainless steel/weathering steel, or enhancing equipment durability through surface treatment technologies such as hot-dip galvanizing and multi-layer heavy-duty anti-corrosion coatings.

Temperature requirements: In high-temperature environments, such as specific work areas in steel smelting and other industrial sites, we should prioritize the use of high-temperature-resistant special alloys and heat-resistant functional components. For the overhead crane's electrical control unit, we need to equip it with multi-layer composite thermal insulation protection. By implementing enhanced thermal management measures, we can effectively ensure the stable operation of the equipment under extreme heat radiation conditions and eliminate operational hazards caused by abnormal temperature rise.

Please provide your basic information, such as application scenario, lifting height, span, voltage, etc., according to the above parameter requirements. We will design the most suitable lifting solution for you and provide detailed drawings and quotations.

| Item | Data |

| Capacity | 0.5-10 ton |

| Span | 3-28.5 m |

| Lifting height | 4-30 m |

| Lifting speed | 0.8-8 m/min |

| Cross-traveling speed | 5-30 m/min |

| Long travelling speed | 10-45 m/min |

| Working class | ISO A3-A5/FEM 1AM-FEM 2M |

| Power source | As your demands |

Newcore specializes in providing comprehensive solutions for 3-ton overhead cranes, including European standard, suspended, and low-headroom configurations. We also offer custom designs tailored to your specific application. With over 20 years of industry experience and extensive technical expertise, our products have been exported to over 160 countries and regions worldwide, establishing a strong reputation in the global lifting equipment market.

We are committed to providing efficient, low-maintenance, and reliable lifting systems to customers across various industries, helping them optimize their handling processes and improve operational efficiency. If you require a custom 3-ton overhead crane, please feel free to contact us for a customized solution and quote.

Q1: What is the lifting height of a 3-ton overhead crane?

A: Typically 6–30 meters, but can be customized based on your workshop space.

Q2: How much does a 3-ton overhead crane cost?

A: Prices start from USD 2,000 and vary depending on configuration and features.

Q3: Can you design a crane for outdoor use?

A: Yes, we provide weatherproof and wind-resistant outdoor designs.

Q4: What power supply does it require?

A: Standard is 380V/50Hz/3ph AC, but we customize it to your regional voltage.

Q5: Do you provide installation and after-sales service?

A: Yes, we offer on-site installation guidance and lifetime technical support.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China