The 2-ton gantry crane is a lightweight lifting device widely used in workshops, warehouses, maintenance stations, and construction sites, primarily for lifting and moving heavy materials.

The 2-ton gantry crane is a lightweight lifting device widely used in workshops, warehouses, maintenance stations, and construction sites, primarily for lifting and moving heavy materials. Its exceptional maneuverability and flexibility adapt to a variety of operational needs, making it particularly suitable for applications requiring flexible positioning and where fixed lifting equipment is impractical. It is a practical device for improving material handling efficiency.

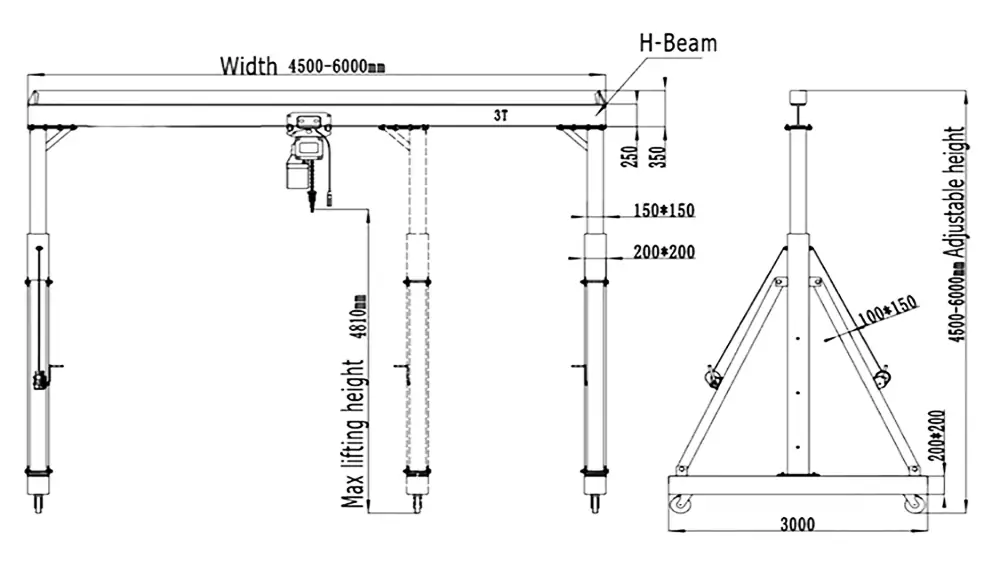

The 2-ton gantry crane has a simple and stable structure. Its core components include:

Horizontal beam : As the main load-bearing component, it supports the lifting load and ensures the stable movement of materials in the horizontal direction.

Support legs : symmetrically distributed on both sides of the beam, providing stable support for the entire equipment and ensuring that the equipment does not tilt during lifting.

Travel wheels : installed at the bottom of the outriggers, most of which are equipped with braking function to facilitate the movement or fixation of the equipment in the work site, and improve the maneuverability and safety of the equipment.

Equipped with an electric hoist and electric drive system, it enables automatic material lifting and motorized travel, resulting in high operational efficiency. Suitable for high-frequency, heavy-load lifting operations in industrial production scenarios (such as production lines and material turnover in large warehouses), it effectively reduces labor costs and improves work efficiency. However, it relies on a mains power supply, resulting in a higher initial purchase cost than manual gantry cranes.

Relying on manual operation to move equipment and lift materials, this type of lift typically works with a chain hoist and does not require a power source. Suitable for light-load, low-frequency lifting operations (such as small repair stations and temporary material handling in small factories), it offers low cost, simple maintenance, and independence from power constraints. However, it offers lower efficiency and is unsuitable for high-frequency, heavy-load operations.

The height and span of the crossbeam can be flexibly adjusted to meet actual operational needs, adapting to the lifting needs of materials of different sizes and varying operating spaces (such as multi-purpose workshops and multi-material handling scenarios). Its advantage lies in its adaptability and ability to handle diverse lifting tasks, but its structure is relatively complex and its cost is slightly higher than that of a fixed gantry crane.

Typically constructed from aluminum alloy, these cranes are lightweight, corrosion-resistant, and easy to disassemble and reassemble. They are particularly well-suited for applications requiring frequent equipment transfers. Aluminum alloy resists rust and can withstand humid or dusty environments, but its load-bearing capacity is lower than that of steel models , making it more suitable for lighter loads and high-precision operations.

| Specificaties | General Parameters |

| Hefcapaciteit | 0.5-10 tons |

| Hefhoogte | 1 meter - 10 meters |

| span | 2 meters - 12 meters |

| Lifting mechanism | kettingtakel |

| Protection level | IP55 |

| Operating temperature | normal temperature |

Work site conditions: The size of the site, the flatness of the ground, and whether there is power supply need to be considered.

Lifting demand intensity: Select the matching drive mode and structural strength based on the operation frequency , single lifting weight and single lifting time .

Material characteristics: Determine the appropriate lifting capacity, lifting height and span based on the material's weight, size and handling path .

Mobility: If you need to frequently move your work location, you should give priority to models that are lightweight and easy to assemble and disassemble .

Environmental adaptability: For outdoor operations, the equipment's rain and sun protection performance must be considered. If the environment is a long-term humid environment such as a port or dock, attention must be paid to whether the protection level meets the standards.

Nucleon is a professional gantry crane manufacturer and supplier, we have 20 years production experience. If you're looking for the right lifting equipment for your application, or have questions about model selection or parameter customization, please feel free to contact Nucleon. Fill out the online inquiry form or call our customer service hotline. Our professional design team will provide you with a customized selection plan and preferential quote. Let professional lifting equipment become your partner in improving operational efficiency and ensuring production safety.

Professionele hijskraanleverancier, toegewijd aan de productie van bovenloopkranen, portaalkranen, zwenkkranen en elektrische takels enz.

Crane Industry Zone, Changyuan City, provincie Henan, China