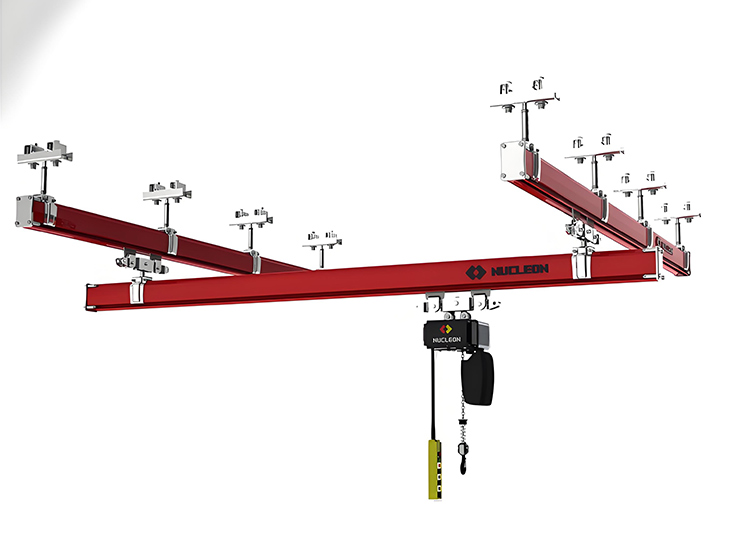

KBK cranes are important handling equipment in modern industrial production, and their safety and reliability directly affect production efficiency and operational safety. Regular daily inspections and periodic maintenance not only prevent sudden failures but also effectively extend the service life of the equipment. This article will systematically outline the key inspection items and maintenance points for KBK cranes to help you achieve safe and efficient operation of the equipment. Please continue reading.

1. Daily Inspection (We suggest doing this before using it every day)

| Inspection Items | Inspection Items |

| Appearance Inspection | Inspect the equipment for deformation, cracks, rust, and other abnormalities, paying particular attention to moving parts and support structures. |

| Tracks and Pulleys | The track should be straight and free of foreign objects, the pulleys should rotate smoothly, and lubrication should be adequate. |

| Electrical System | Inspect the cable insulation, check that the joints are secure, ensure that the switches are sensitive, and verify that the control panel indicator lights are functioning normally. |

| Load Test | Operate the equipment under no load or rated load conditions and observe whether it runs smoothly. |

2. Regular Maintenance (We suggest doing this monthly or quarterly)

| Maintenance Projects | Maintenance Details: | Maintenance Recommendations |

| Cleaning and Lubrication | Remove dust and dirt, and lubricate moving parts such as pulleys and guide rails. | Use lubricants recommended by the manufacturer to reduce wear and extend service life. |

| Mechanical Component Inspection | Check the operating status of key components such as motors, reducers, and brakes. | Pay close attention to any abnormal noises or overheating. |

| Safety Device Inspection | Verify that limit switches and overload protection devices are functioning properly. | Ensure that the equipment can automatically shut down in the event of an abnormality to prevent accidents. |

| Electrical System Maintenance | Check electrical connections and perform insulation tests if necessary. | Prevent faults caused by electrical short circuits or poor contact. |

| Records and Feedback | Create an equipment inspection and maintenance log to record any issues and their resolution. | Establish a traceability mechanism to facilitate subsequent optimization of maintenance strategies. |

3. Professional Technical Support Recommendations

During inspection or maintenance, if you encounter issues where the cause of the fault is unclear or the technical difficulty is high, it is recommended to contact professional personnel promptly.

Nucleon Crane, a professional KBK crane manufacturer with over 20 years of industry experience, specializes in customized services for KBK lifting systems, jib cranes, and intelligent lifting solutions. Our products are widely applied across various industries such as precision manufacturing, automotive assembly, and new energy. We not only provide lifting equipment solutions but also offer comprehensive technical support and services throughout the entire lifecycle of your equipment.

IV. Conclusion

In summary, the safe and stable operation of KBK cranes is inseparable from daily inspections and long-term maintenance management. Through scientific maintenance, enterprises can not only improve operational efficiency and reduce equipment downtime, but also effectively control operating costs. If you would like to learn more about our products or obtain a professional customized solution, please feel free to contact us at any time.