EOT cranes are indispensable in modern industrial operations, effectively facilitating efficient material handling across a wide range of industries. Among the most widely used variants, single-girder and double-girder EOT cranes each offer unique designs tailored to specific operational requirements. Making an informed choice between the two ensures safe and efficient operation of the equipment. Key to this selection lies in understanding their infrastructure, application scenarios, equipment specifications, maintenance requirements, and overall suitability. This article will explore these aspects in detail to help industry professionals select the crane that best suits their needs.

Crane Structure And Design

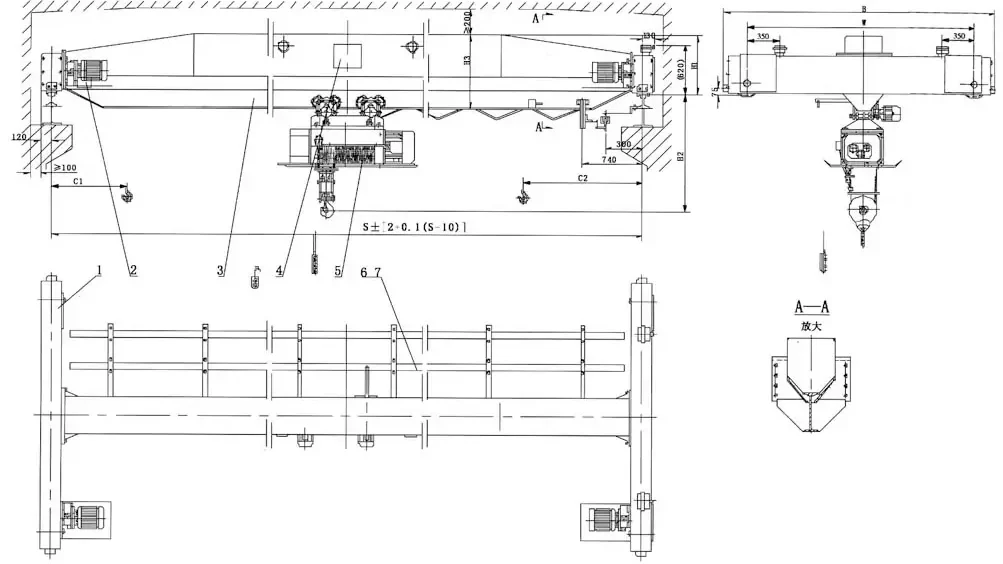

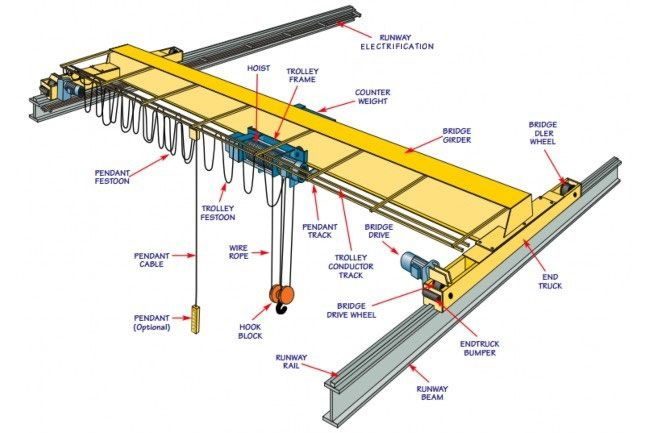

Single-girder EOT cranes feature a main beam that spans the width of the work area. The main beam is typically box-type or pergola-type, the latter offering greater wind resistance. The main beam is typically constructed of rolled steel or high-quality steel plate. The hoisting mechanism consists of a crane that travels along rails attached to the ground or floor, and a wire rope hoist that moves along the single beam. There are no dedicated maintenance platforms, only small access hatches for motor maintenance, and generally no underbridge lighting.

Double-girder EOT cranes consist of two parallel main girders spaced a certain distance apart and connected by a crossbeam. The hoisting mechanism is mounted atop the two main girders and runs along rails mounted on their upper flanges. Double-girder EOT cranes are equipped with continuous maintenance platforms along both girders and are often equipped with underbridge lighting. The drive system typically utilizes a base-mounted motor and a horizontal gearbox.

Toepassing

The structural and strength differences between single-girder and double-girder EOT cranes make them suitable for different applications, each suited to specific operational requirements.

Single-girder EOT cranes are primarily designed for light-to-medium loads, where cost-efficiency and space efficiency are paramount. Single-girder EOT cranes are commonly found in small and medium-sized factories, warehouses, and assembly lines. In warehouses, they excel at handling palletized cargo, boxes, and small mechanical parts, where load requirements are relatively modest. Their compact design makes them ideal for facilities with low headroom, such as workshops with low ceilings or buildings that cannot accommodate larger cranes. Single-girder cranes are also popular in industries with intermittent operations, such as auto repair shops, where they are used intermittently to lift engines or other components. Additionally, due to their low initial cost and quick installation, single-girder EOT cranes are well-suited for temporary installations or projects with short-term material handling needs.

Double-girder EOT cranes, on the other hand, are designed for heavy-duty, high-frequency operations in demanding industrial environments. They are widely used in large manufacturing plants, including steel mills, automotive plants, and aerospace facilities. Ports and rail yards rely on double-girder cranes to load and unload containers, bulk cargo, and heavy equipment, as their robust construction withstands the rigors of continuous use. Mining operations also use these cranes to move ore, coal, and large mining machinery under harsh conditions. Double-girder cranes are also common in high-temperature, highly corrosive environments such as power plants, foundries, and chemical facilities. Their stronger construction allows them to accurately and reliably handle heavy loads in these harsh environments. Equipment Specifications

Specificaties

| Parameter | Single Girder EOT Crane | Double Girder EOT Crane |

| Hefcapaciteit | Usually 1-32 tons | 5-800 tons |

| Span Length | 7.5-31.5 meters | 10.5-40.5 meters |

| Hefhoogte | 3.2-40 meters | 12-60 meters |

| Arbeidersklasse | A1-A5 | A3-A8 |

| Speed Parameters | Lifting speed: 0.32-16 m/min; Travel speed: 3.2-50 m/min | Lifting speed: 0.63-63 m/min; Travel speed: 16-110 m/min |

Maintenance

Proper maintenance is essential to ensure the lifespan, safety, and efficiency of both single-girder and double-girder EOT cranes. While maintenance requirements vary depending on the complexity of their design, regular maintenance is crucial for both types of cranes.

Single-girder EOT cranes are relatively easy to maintain due to their simple structure. Regular inspections should focus on the electric hoist, trolley system, and main girder. Hoist components, such as the motor, brake, and gearbox, should be inspected for wear and lubricated according to the manufacturer's recommendations. Trolley wheels and rails must be checked for alignment and signs of damage, as trolley derailment can cause excessive wear and reduce operating efficiency. Main girder inspections should be conducted for cracks, deformation, or corrosion, particularly at connection points. Since single-girder cranes lack dedicated maintenance platforms, inspections may require the use of ladders or scaffolding, which should be performed with caution to ensure safety. It is also important to inspect the electrical system for signs of damage or overheating.

Double-girder EOT cranes require more comprehensive maintenance due to their complex design and heavy use. Maintenance platforms along the main girder provide easy access to critical components, making inspections more efficient. Key areas requiring inspection include the trolley or winch, main girder, crossbeam, and operator's cab. Trolley wheels, gears, and bearings should be regularly lubricated and inspected for wear, and winch ropes or chains must be inspected for wear, corrosion, or stretch. Inspect the main and cross beams for cracks, deformation, or corrosion, paying particular attention to welds and joints. Check the underbridge lighting system to ensure proper operation, as it is crucial for safe operation in low-light conditions. Electrical systems require regular testing to ensure proper operation and prevent malfunctions. Additionally, attention should be paid to the controls, seats, and safety devices in the operator's cab to ensure operator safety.

For both types of cranes, a regular maintenance schedule should be established based on the manufacturer's guidelines and the frequency of crane use. Daily, weekly, monthly, and annual inspections should be rigorously performed, with more detailed inspections required the longer the equipment is in operation. Any issues discovered during inspections should be addressed promptly to prevent further problems. Keep detailed maintenance records, including inspection dates, repairs performed, and replacement parts used, so that subsequent operators can track crane performance and plan future maintenance.

Conclusie

When choosing between single-girder and double-girder EOT cranes, factors such as load requirements, span length, available space, frequency of operations, and budget must be considered. By carefully evaluating these factors and understanding the unique characteristics of each type, industry professionals can select the crane that best meets their operational needs, ensuring safe, efficient, and cost-effective material handling for years to come. Ultimately, both types of cranes play an important role in modern industry, contributing to increased productivity and operational success across a wide range of sectors.