EOT cranes are commonly used lifting equipment in industrial plants and warehousing logistics for the horizontal transportation and lifting of heavy loads. The precise movement of heavy loads relies on the coordinated operation of numerous EOT crane parts, making an understanding of these parts essential for equipment maintenance and safe operation. This article will break down the key components of an EOT crane.

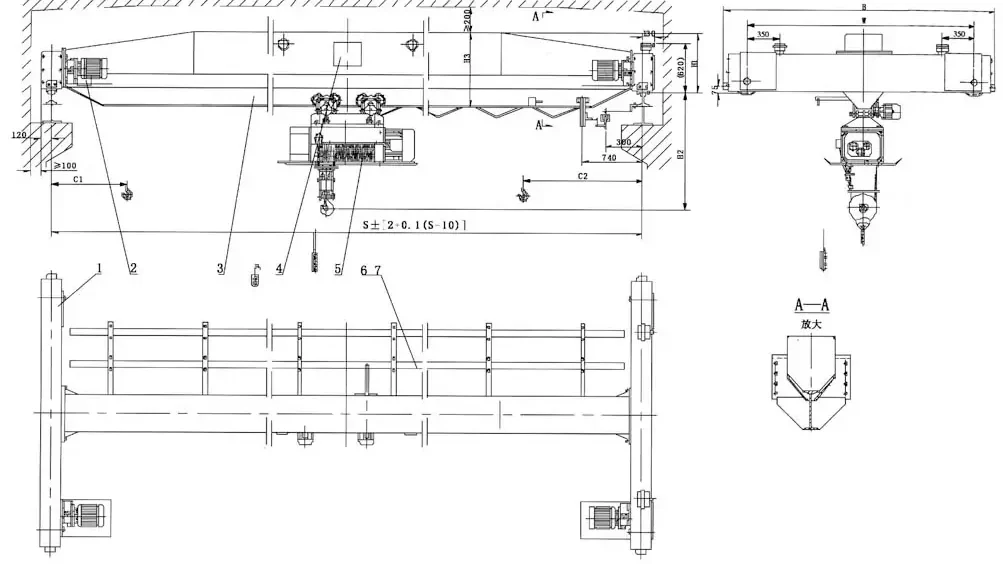

EOT Crane Design

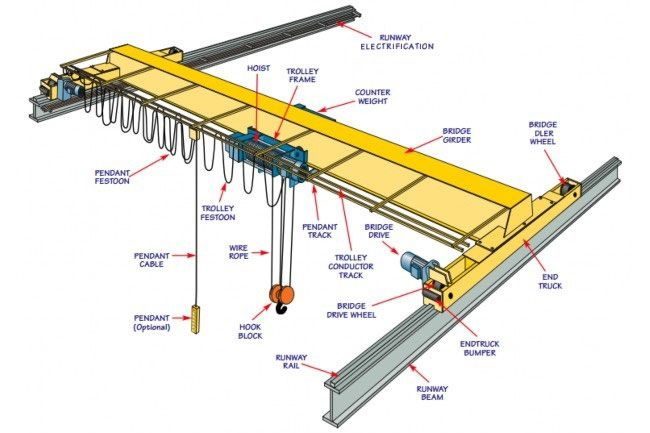

The crane's structure and design cleverly integrate several key components: the bridge, the main load-bearing structure, supports the laterally movable trolley, which in turn carries the hoist for lifting and lowering. End beams at each end drive the entire structure along the track, a control system coordinates all movements, and safety devices such as buffers provide protection. These components work together to achieve efficient handling of heavy objects.

EOT Crane Parts

After gaining a thorough understanding of the structure of an EOT crane, we can proceed to dissect its key components. The following sections will systematically explain the functions and roles of each major part, from the bridge structure to the control system, helping you fully grasp the core construction of an EOT crane.

Bridge

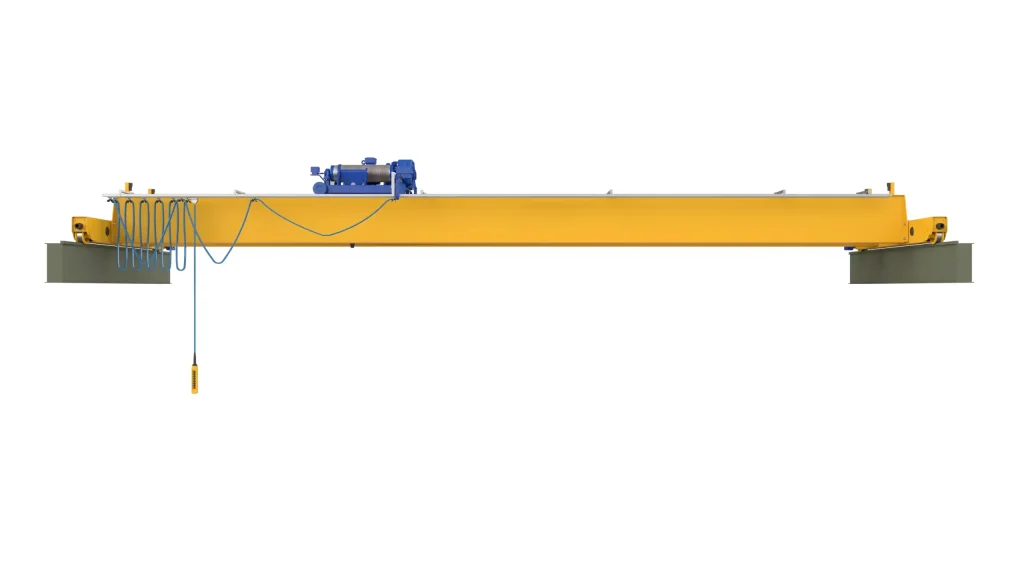

The bridge is a key EOT crane part, serving as the main structure of the crane. It spans the working area, supports the trolley and winch, and bears the weight of hoisted objects.Types of this EOT crane part include single beam, double beam and box beam. Single beam is suitable for light-duty operations, double beam for heavy-duty operations, and box beam offers both high strength and rigidity.The bridge is usually made of high-strength steel, and some main beams are designed to be arched to increase load-bearing capacity and reduce trolley operation problems.

End Beam

The end beams are an important EOT crane part located at both ends of the bridge. They contain wheels, motors and drive devices inside to drive the crane to move along the track. This EOT crane part consists of wheels, motors, and limit switches. The number of wheels depends on the load capacity, the motors provide power for movement, and the limit switches prevent the crane from crashing into buildings. There are two driving modes for this EOT crane part: separate drive and centralized drive. Separate drive relies on the rigidity of the bridge to maintain synchronization, while centralized drive has good synchronization and is suitable for small tonnage cranes.

Trolley

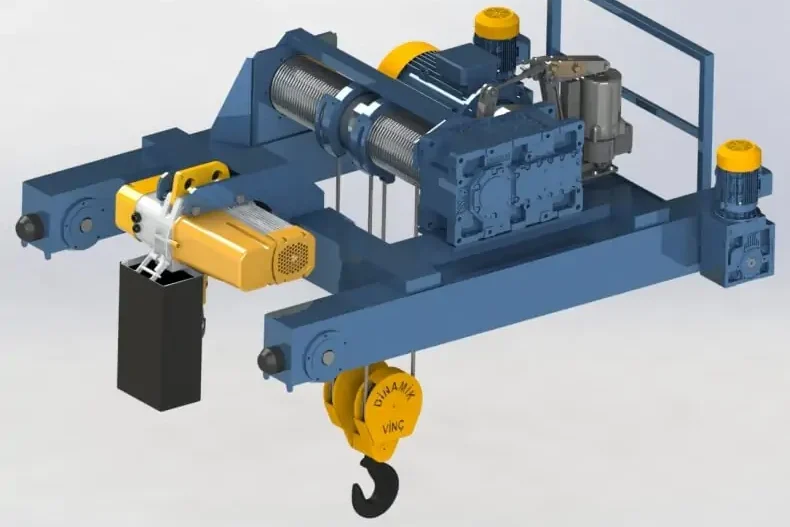

The trolley is a vital EOT crane part, functioning as the laterally moving component that carries the winch. It can move along the bridge to achieve horizontal transportation of heavy objects. The trolley has two types: upper running and lower hanging, running on the top track of double beams and the lower flange of single beam respectively. It consists of a trolley frame, a running mechanism, and a limit switch. The trolley frame supports the weight, the running mechanism drives it to move, and the limit switch prevents collisions—all integral to this EOT crane part.

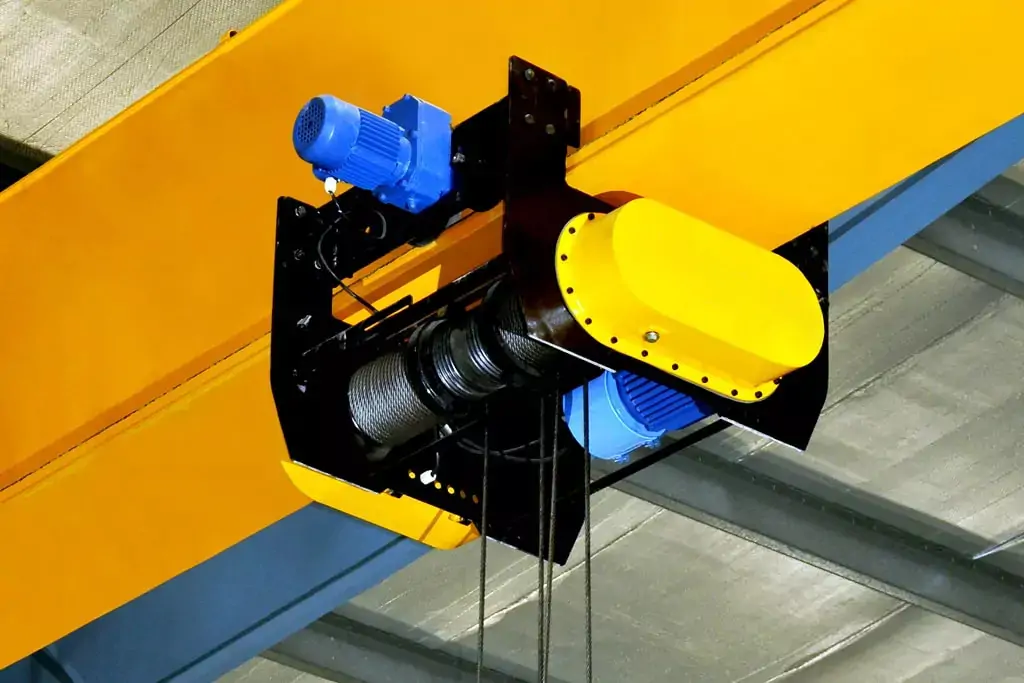

Winch

The winch is a core EOT crane part for lifting, responsible for lifting and hovering heavy objects, and installs on the trolley. The winch mainly consists of a motor, a drum, a wire rope or chain, and a hook assembly. The motor provides power, the drum winds the rope, the hook assembly hangs the load, and it has a safety device to prevent the load from falling off. The hooks in large-tonnage EOT cranes usually include a main hook and an auxiliary hook. The main hook is used to lift heavy objects, while the auxiliary hook is used to lift light objects, thereby improving work efficiency.

Track System

The track system is a supporting EOT crane part, made up of rails and support structures that provide a path for the crane to move. Rails of the track system mount on track beams, which guide the crane's movement, while the track beams distribute the weight to the building. The tracks of the track system need alignment to prevent derailment, and stops at the ends limit the crane's travel.

Control System

The control system is an operational EOT crane part that manages the crane's movement and speed to ensure safe operation. EOT crane control systems generally use button boxes, remote controls and driver's cabs for control. The button box suits close-range operation, the remote control offers flexibility, and the cab works for precise control of heavy cranes. This EOT crane component must include safety features such as a main contactor to cut power in an emergency and a variable frequency drive for smooth acceleration and deceleration.

Buffers and Safety Devices

Buffers and safety devices are protective EOT crane parts. As part of these components, buffers are installed at the end of the bridge, trolley or track to reduce the impact of collisions. A passive safety component of the EOT crane, the overload limiter can prevent the lifting of overweight cargo and ensure construction safety. Wheels are of course an important part of the EOT crane components. When the wheels have cracks, excessive wear, etc., they need to be replaced in time.

Conclusion

In summary, the efficient operation of a crane depends on the precise coordination of its various components—from the load-bearing bridge and the end beams that drive its movement, to the trolleys that enable lateral movement and the winches that perform lifting and lowering operations, to the track systems that guide the path, the control systems that regulate and control operations, and the buffers and limiters that ensure safety. Each component plays an irreplaceable role in its design and positioning. It is this organic unity of structure and function that enables cranes to adapt to diverse industrial scenarios and reliably complete various heavy-lifting tasks. Understanding these EOT crane parts can help us better maintain and operate electric overhead cranes, ensuring their safe and efficient operation.If you need to replace parts on your overhead crane, consult Nucleon to meet your equipment needs.