Choosing the right lifting equipment for any lifting operation is crucial for improving construction efficiency and reducing operating costs. Portal cranes and gantry cranes are two of the most common types of lifting equipment, each offering unique advantages and suiting different operating scenarios. This article aims to help readers understand the differences between portal crane VS gantry crane, enabling decision-makers to make more informed choices and ultimately gain new competitive advantages.

Basic differences between portal cranes and gantry cranes

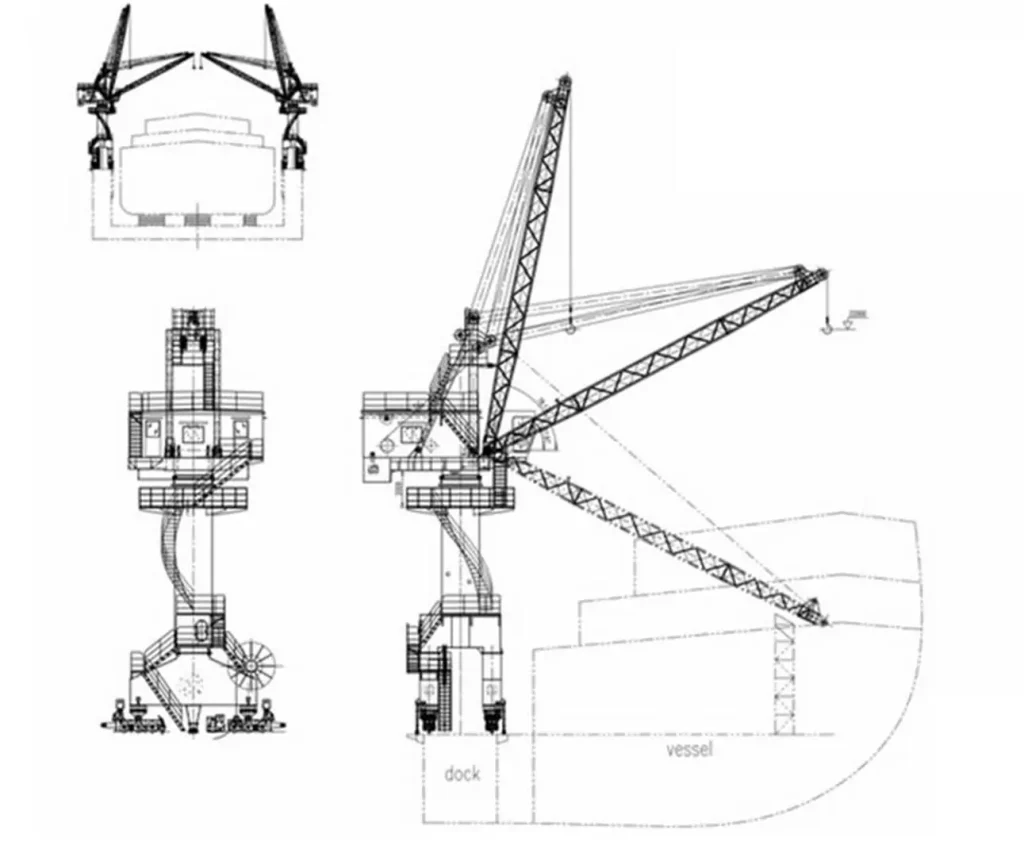

Portal cranes are based on a rotating gantry structure with 360° rotation. A portal crane's characteristic is that its rotating boom adjusts the operating radius through luffing motion. Its motion path follows a fan-shaped or cylindrical footprint centered on the portal base, enabling multi-directional operations from a fixed point. Its design emphasizes flexibility and adaptability to unstable terrain. It has less stringent requirements for track parallelism and straightness, and its gantry can accommodate railroad cars or other ground vehicles underneath.

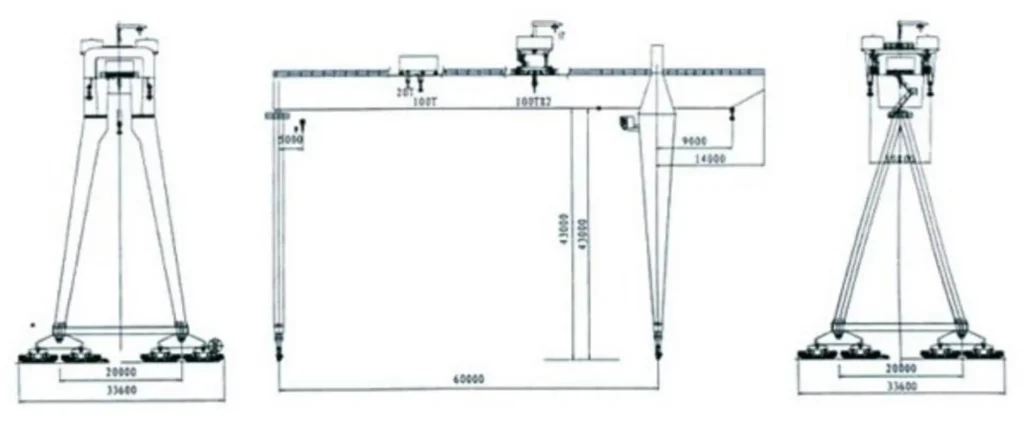

Gantry cranes, on the other hand, have a "gate"-shaped frame consisting of two legs and a crossbeam. They lack a rotating mechanism and rely on the trolley's linear motion along the track and the trolley's translation along the crossbeam. Their motion path follows a rectangular, linear footprint. Gantry cranes typically have larger spans and greater structural stability, but they also demand higher track parallelism and foundation strength, resulting in a more fixed operating path.

Application Scenarios and Industries

Portal cranes are suitable for applications requiring frequent transfers and multi-directional operations, where their flexibility is particularly advantageous.

Ports and docks: Portal cranes are suitable for loading and unloading breakbulk, bulk cargo, and containers. They particularly excel at navigating height differences between vessels of varying tonnage due to tides or cargo loads, enabling more efficient ship-to-shore cargo transfers.

Shipyards and hydropower stations: They lift ship sections, install equipment, and lift prefabricated components in dam construction. The multi-directional rotation of portal cranes allows them to cover slipways or construction areas.

Forest Products and Biomass Industry: Portal cranes are suitable for stacking, loading, unloading, and feeding materials in lumber and biomass yards, adapting to irregular cargo distribution.

Gantry cranes are suitable for fixed locations and single-direction movement.

Container yards and railway freight yards: Gantry cranes can stack and transfer cargo in rows along the tracks, while also covering large storage areas with their long-span crossbeams. Factory production lines and heavy-duty

workshops: Due to their high load capacity, they often serve industries such as steel and machinery to move heavy equipment and transfer steel billets, adapting to fixed material flow processes.

Construction sites and bridge construction: They hoist building materials, precast beams, and other components. Their more stable gantry structure suits heavy construction sites.

Structure and Support Method

The portal crane structures around a rotating gantry, consisting of a portal base, a rotating tower, and a luffing boom. The main beam is typically a truss structure. It adopts a simple support method, requiring only a standard ground track laid on a gravel bed or simple concrete foundation. The track can adapt to unstable terrain and eliminates the need for complex foundation preparation. The gantry typically has four legs in its design, forming a portal structure that allows rail or ground vehicle access. The center of gravity concentrates in the portal base area, and bearings connect rotating components to ensure stability.

Gantry cranes consist of two rigid legs and a box-shaped crossbeam, on which a movable trolley mounts for lifting operations. They rely on fixed tracks laid along the ground for support. Wheel assemblies connect the outriggers to the tracks. The tracks must be strictly parallel and have a solid foundation. The wide spacing between the outriggers provides strong load-bearing capacity. Some models feature a cantilever structure to expand the operating range. While the overall structural stability is outstanding, gantry cranes demand relatively high foundation flatness.

Maintenance

Maintenance for portal cranes focuses on the swivel and luffing mechanisms. Operators must regularly inspect the swivel bearing lubrication and gear meshing clearance to prevent component wear caused by swivel jamming. They should also pay special attention to the cylinder seals of the luffing boom hydraulic system to prevent oil leaks that could cause safety incidents and affect operational accuracy. Portal cranes utilize regenerative braking technology, which returns energy during descent or deceleration to the grid, reducing energy consumption and brake component wear. The structural design also minimizes long-term maintenance requirements for the tracks and gantry, resulting in a moderate level of overall operation and maintenance complexity.

Gantry crane maintenance hinges on its linear motion components. Operators must frequently inspect the track parallelism between the gantry crane and the trolley to prevent track gnawing caused by track misalignment. The gantry crane's dual-rigid outrigger structure is particularly sensitive to lateral loads, making it susceptible to track wear due to uneven force distribution. They must also carefully monitor the tightness of the bolts connecting the crossbeam and outriggers to prevent loosening due to vibration. While gantry cranes are more complex to install, their structural stability allows for long-term operation, requiring less maintenance than the rotating mechanism of a portal crane.

Cost

Portal cranes have lower initial investment and operating costs than gantry cranes. Initially, they require only standard ground tracks, eliminating the need for deep, heavy foundations, making installation significantly less expensive than gantry cranes. During operation, their regenerative braking technology reduces energy consumption, and the rotating and luffing mechanisms require less maintenance than the track system of a gantry crane. Furthermore, they can integrate multiple operations, such as loading, unloading, transport, and stacking, reducing equipment and personnel investment and further reducing operating costs.

Gantry crane costs are primarily concentrated in the initial stages. Constructing the deep, heavy foundations and high-precision rails required for them is expensive, resulting in a significantly higher initial investment than portal cranes. While their structural stability is strong during long-term maintenance, costs for repairing rail wear and calibrating rigid outriggers are still higher than for regular portal crane maintenance. However, their long-span design allows for a wider operating range, and their high efficiency in heavy, high-frequency linear operations reduces unit costs.

Customization and Control Methods

Portal cranes generally offer a high degree of customization, focusing on adaptability to specific workloads. They can customize spreaders for different cargo types, such as lumber, bulk cargo, and containers. To accommodate spatial constraints in locations like ports and shipyards, operators can adjust the rotation angle and boom length. Some models have anti-sway systems to enhance high-precision operations.

Operators primarily control portal cranes from the operator's cab, which integrates intelligent sensing technology to optimize operating paths and adapt to multi-directional operations in complex environments.

Gantry cranes offer customization in both their structural form and expanded functionality. Manufacturers can customize gantry cranes with double, single, or no cantilever configurations depending on the operational scope, and design them with varying spans and tonnages based on load-bearing requirements.

Manufacturers design gantry cranes for applications such as container yards and workshops, offering a variety of control options, including ground-based wireless remote control and cab-operated operation. Some models integrate automated dispatching systems, adapting to large-scale, standardized linear operations. Their versatility allows them to adapt to diverse needs, from light warehousing to heavy engineering projects, through structural adjustments.

Conclusion

Portal cranes and gantry cranes each offer advantages in their structure and application. Choosing the right crane not only improves operational efficiency but also significantly optimizes operating costs. Whether pursuing optimal and superior lifting performance or improving overall logistics efficiency, choosing the crane that best suits your needs is a wise decision for business growth.