Choosing between a single girder EOT crane and a double girder EOT crane is a critical decision that impacts your operation's safety, efficiency, and cost.

This article will analyse the differences between the two in terms of structure, application scenarios, technical specifications, and maintenance, helping you to precisely select the most suitable bridge crane for your requirements.

Crane Structure And Design: A Comparative Look

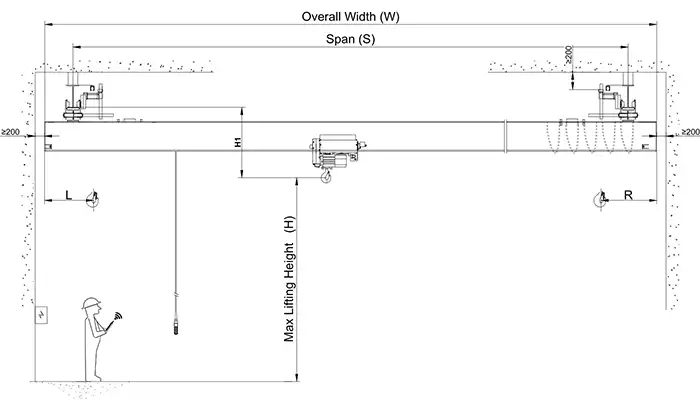

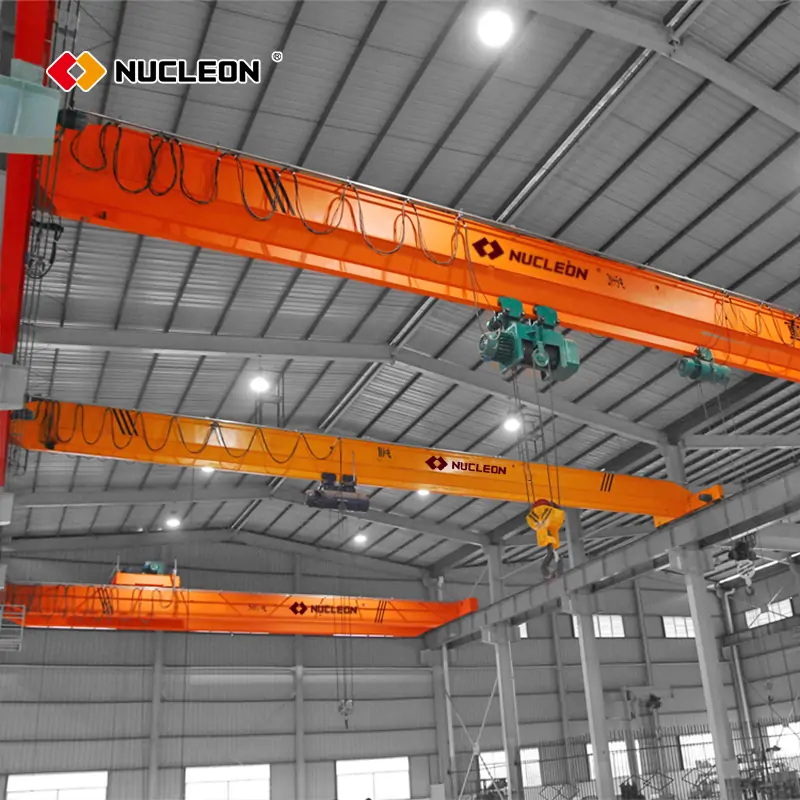

Single Girder EOT Crane Design

Single-girder EOT cranes feature a main beam that spans the width of the work area.

The main beam is typically box-type or pergola-type, the latter offering greater wind resistance. The main beam is typically constructed of rolled steel or high-quality steel plate. The hoisting mechanism consists of a crane that travels along rails attached to the ground or floor, and a wire rope hoist that moves along a single beam.

There are no dedicated maintenance platforms, only small access hatches for motor maintenance, and generally no underbridge lighting.

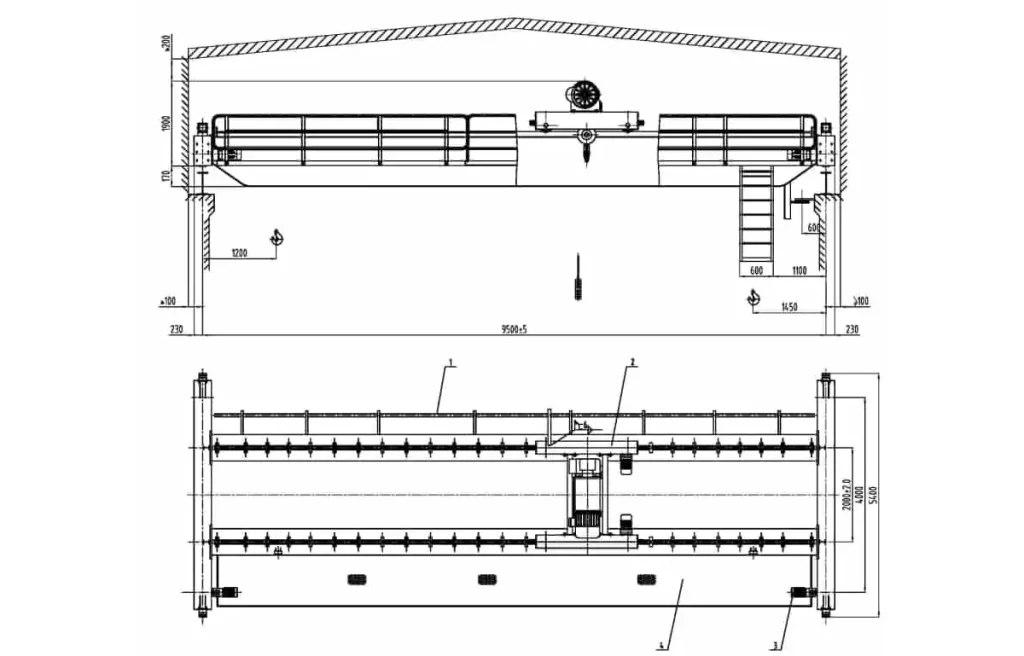

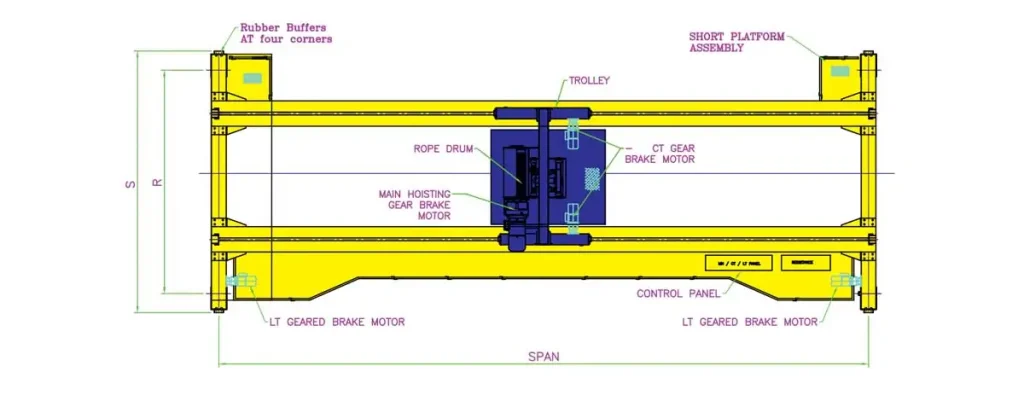

Double Girder EOT Crane Design

Double-girder EOT cranes consist of two parallel main girders spaced a certain distance apart and connected by a crossbeam.

The hoisting mechanism is mounted atop the two main girders and runs along rails mounted on their upper flanges. Double-girder EOT cranes are equipped with continuous maintenance platforms along both girders and are often equipped with underbridge lighting.

The drive system typically utilizes a base-mounted motor and a horizontal gearbox.

Application Scenarios: Matching the Crane to Your Needs

The structural differences directly translate to distinct application scenarios for each EOT crane type.

Where to Use a Single Girder EOT Crane

Single-girder cranes are ideal for light-to-medium duty applications where cost and space are key factors. Common uses include:

Small to Medium Workshops & Warehouses: Handling pallets, boxes, and mechanical parts.

Low-Headroom Facilities: Their compact design is perfect for buildings with height restrictions.

Intermittent Operations: Ideal for auto repair shops, maintenance bays, and production lines with sporadic lifting needs.

Temporary or Short-Term Projects: Thanks to their lower initial cost and quicker installation.

Where to Use a Double Girder EOT Crane

Double-girder cranes are the workhorses for heavy-duty, high-frequency operations.

Demanding Environments: Power plants, foundries, and chemical plants where high temperatures and corrosion resistance are required.

Heavy Industries: Steel mills, automotive manufacturing, and aerospace facilities.

Logistics Hubs: Ports and rail yards for loading/unloading containers and heavy machinery.

Mining & Raw Materials: Moving ore, coal, and large equipment in harsh conditions.

Equipment Specifications: At a Glance

The table below summarizes the key equipment specifications to help you compare single-girder and double-girder EOT cranes technically.

| Parameter | Single Girder EOT Crane | Double Girder EOT Crane |

| Lifting Capacity | Usually 1-32 tons | 5-800 tons |

| Span Length | 7.5-31.5 meters | 10.5-40.5 meters |

| Lifting Height | 3.2-40 meters | 12-60 meters |

| Working Class | A1-A5 | A3-A8 |

| Speed Parameters | Lifting speed: 0.32-16 m/min; Travel speed: 3.2-50 m/min | Lifting speed: 0.63-63 m/min; Travel speed: 16-110 m/min |

Maintenance Requirements: Simplicity vs Comprehensiveness

Proper maintenance is essential for the safety and longevity of any overhead crane.

Maintaining Your Single Girder Crane

Due to their simpler design, single-girder EOT cranes are relatively straightforward to maintain.

Focus Areas: Electric hoist (motor, brake, gearbox), trolley wheels, and main girder.

Inspections: Check for wear, misalignment, cracks, or corrosion. Pay attention to connection points.

Access: As they often lack platforms, inspections may require ladders or scaffolding. Always prioritize safety.

Maintaining Your Double Girder Crane

The complexity and heavy-duty nature of double girder EOT cranes demand more comprehensive maintenance.

Focus Areas: Trolley/winch system, main & cross beams, electrical systems, and operator's cab.

Advantages: Integrated maintenance platforms provide safer and easier access to key components.

Detailed Checks: Regularly inspect winch ropes, gears, bearings, underbridge lighting, and all safety devices.

Universal Maintenance Tips

Act Promptly: Address any issues immediately to prevent downtime and ensure safe operation.

Schedule: Establish a regular schedule (daily, weekly, monthly, annual) based on manufacturer guidelines and usage intensity.

Record Keeping: Maintain detailed logs of all inspections and repairs for tracking performance and planning.

Conclusion

Choosing between a single and double girder EOT crane ultimately depends on your specific operational requirements.

Choose a Single Girder EOT Crane if: Your needs involve light-to-medium loads, you have space or headroom constraints, your budget is a primary concern, and operation is not continuous.

Choose a Double Girder EOT Crane if: You handle heavy or bulky loads, require high speeds and duty cycles, operate in demanding environments, and need maximum hook height and durability.

By carefully evaluating your load requirements, span, headroom, and operational frequency, you can make an informed decision that ensures safe, efficient, and cost-effective material handling for years to come.

Still unsure which crane is the perfect fit for your facility? Contact our experts today for a free consultation and personalized recommendation!