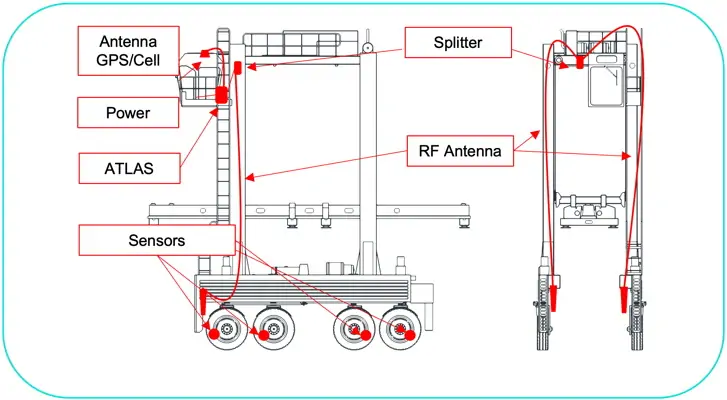

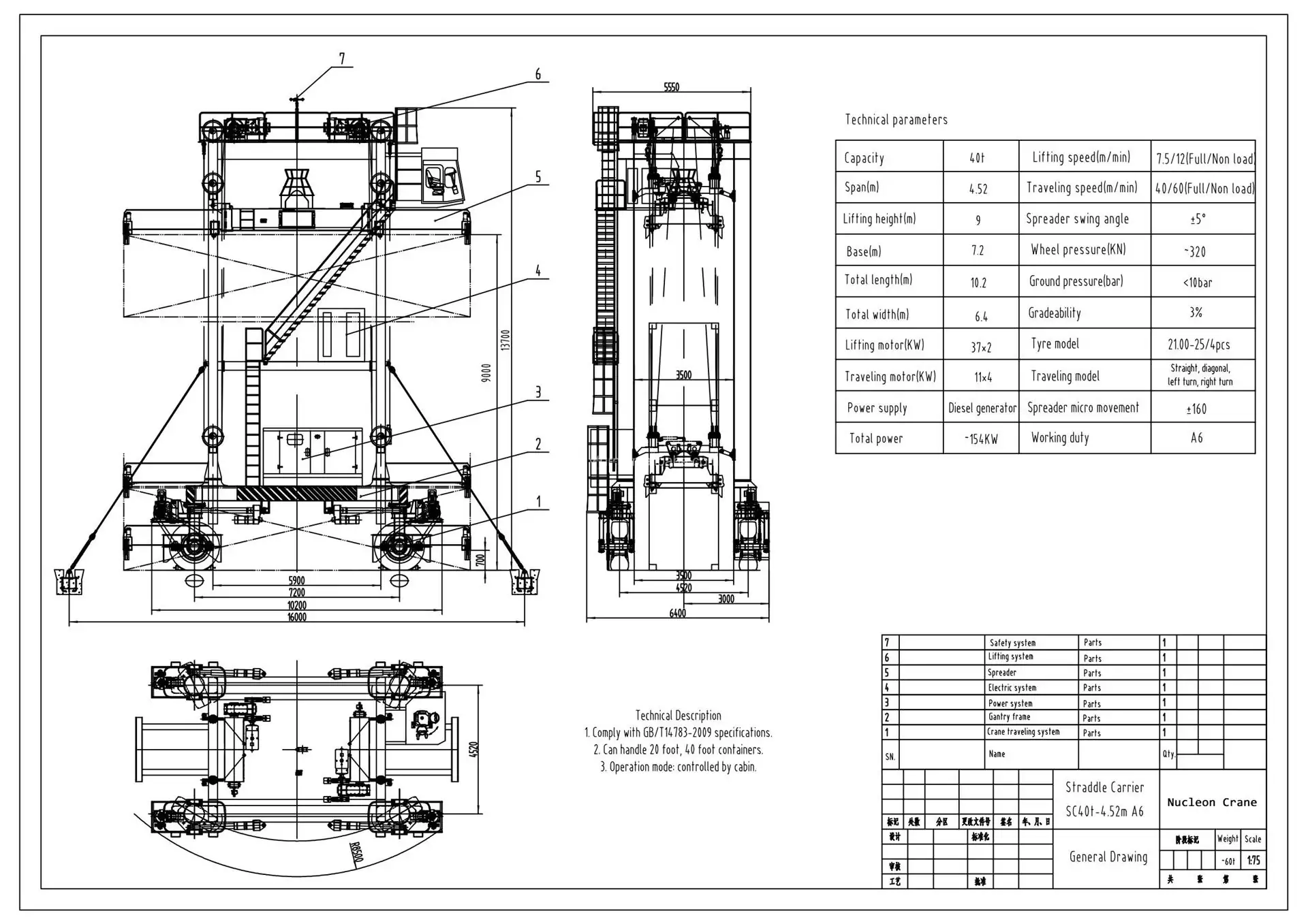

We support a fully customized design of a container straddle carrier, providing the best solution based on yard layout, container specifications, lifting capacity, and level of automation.

The Container Straddle Carrier Crane is a specialized container handling equipment widely used in ports, container yards, logistics terminals, and intermodal transportation centers. It is designed to lift, stack, and transport standard ISO containers efficiently without the need for fixed rails or additional cranes. Straddling the container and lifting it directly from the ground or trailer platform enables flexible, fast, and space-saving container handling operations.

Container straddle carriers are widely used in container handling and yard logistics; it has flexibility, high stacking efficiency, and the ability to operate without fixed tracks. This equipment enables rapid loading, unloading, stacking, and lateral transport while minimizing space requirements, making it the ideal choice for ports, container terminals, logistics centers, and inland yards. Their lifting capacity, span, and drive systems are customizable to suit diverse operational environments and load requirements. Key application scenarios include:

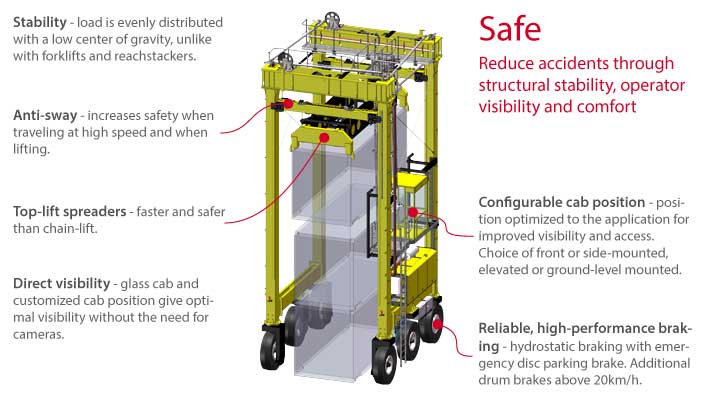

A Container Straddle Carrier Crane is mainly composed of the main frame structure, lifting spreader, hoisting system, drive and steering system, wheel assemblies, and operator control cabin.

Main Frame Structure

Heavy-duty welded steel structure providing stability and strength for continuous stacking and handling tasks.

Lifting Spreader (Container Lifting Frame)

Adjustable ISO twist-lock spreader for securely gripping 20ft/40ft containers with fast locking and high safety.

Hoisting System (Winch + Wire Rope / Hydraulic Lifting)

Ensures stable lifting and lowering with precise control, suitable for heavy and frequent operations.

Drive System (Engine / Electric / Hybrid)

Provides powerful traction and mobility, supporting straight travel, steering, and crab movement for confined yards.

Steering & Wheel System (Rubber Tires / Steering Axles)

Enables smooth maneuvering and tight turning radius, suitable for unpaved or mixed ground conditions.

Operator Cabin & Control System

Ergonomic cabin with wide visibility and intelligent control panels for efficient and safe operation.

| Lifting Capacity (t) | 10 | 16 | 20/10 | 32/10 | 36/16 | 50/10 | |

| Хэмжээ (м) | 18-35 | ||||||

| Өргөх өндөр (м) | 10-13 | ||||||

| Ажлын анги | А5-А8 | ||||||

| Хурд (m/min) | Өргөх | 8.5 | 7.9 | 7.2/10.4 | 7.2/10.4 | 7.8/10.5 | 6/10.4 |

| Trolley | 43.8 | 44.5 | 44.5 | 41.9 | 41.9 | 38.13 | |

| Кран | 40 | 38 | 38 | 40 | 40 | 38 | |

| Motor | Өргөх | YZR180L-6/17 | YZR225M-8/26 | YZR225M-8/26 YZR200L-6/26 | YZR280S-10/42 YZR200L-6/26 | YZR280M-10/55 YZR225M-6/34 | YZR280M-10/55 YZR200L-6/26 |

| Trolley | YZR132M1- 6/2.5*2 | YZR132M2- 6/4*2 | YZR132M2- 6/4*2 | YZR132M1- 6/4*2 | YZR132M1- 6/6.3*2 | YZR132M1- 6/6.3*2 | |

| Кран | YZR160L-6/13*2 | YZR160L-6/13*2 YZR160M1- 6/6.3*4 | YZR160L-6/13*2 YZR160M2- 6/8.5*4 | YZR160M2- 6/8.5*4 | YZR160L-6/13*4 YZR160M2- 6/8.5*4 | YZR160L-6/13*4 | |

| Weight (t) | Trolley | 9 | 9.5 | 12 | 16 | 18 | 24 |

| Total | 63.2-100 | 78-106 | 79-120 | 95-108 | 106-155 | 195 | |

| Wheel Pressure (KN) | 225-295 | 255-373 | 208-289 | 324-334 | 314-363 | 452 | |

| Steel Track | 43kg/m | 50kg/m | |||||

| Эрчим хүчний эх үүсвэр | 3-phase A.C 380V 50HZ (As your demand) | ||||||

Please provide your yard layout, container dimensions, and operational capacity requirements. We will recommend suitable models and provide a customized quote.

Nucleon Crane is a professional Straddle Carrier Crane manufacturer and supplier in China, dedicated to providing efficient container handling solutions for ports, terminals, rail yards, and logistics centers. We have strong in-house R&D and engineering capabilities, we support full custom design according to yard layout, container specifications, lifting capacity, and automation levels.

We have an experienced technical team, we offer comprehensive project support including site planning, equipment selection, installation guidance, operator training, spare parts supply, and long-term after-sales services. Whether you require standard models or fully customized systems, we deliver one-stop container yard handling solutions that enhance workflow efficiency and reduce operational costs.

Tell us your application scenario and capacity requirements, our engineering team will provide a tailored solution and quotation.

What are the uses of a straddle carrier?

A straddle carrier is primarily used for lifting, transporting, and stacking containers within ports, container terminals, and logistics yards. It allows direct pickup and placement without additional lifting equipment, improving container flow efficiency and reducing yard congestion.

What are the maintenance requirements for a straddle carrier?

Regular maintenance includes checking the hoisting wire/chain, lubrication of moving parts, hydraulic system inspection, tire condition monitoring, and periodic calibration of control systems. Preventive maintenance schedules are recommended to ensure reliability and extend service life.

How does a straddle carrier compare to other container handling equipment?

Unlike rail-mounted gantry cranes or reach stackers, a straddle carrier offers greater maneuverability and independent mobility, does not require rail tracks, and can lift and carry containers simultaneously. It is ideal for high-efficiency yard operations where flexibility and fast container movement are essential.

What are the different types of straddle carriers?

Common types include diesel-powered, electric, and hybrid-drive models. They can also be classified by stacking height (1-over-1, 1-over-2, 1-over-3) and level of automation (manual, semi-automatic, fully automated yard carrier).

What are the safety considerations when operating a straddle carrier?

Operators must ensure stable load handling, avoid sudden movements, maintain clear visibility, and follow rated lifting limits. Work areas should be free from obstacles, and routine checks of brakes, alarms, and emergency stop systems are essential for safe operation.

Өргөх тогорууны мэргэжлийн ханган нийлүүлэгч нь гүүрэн тогоруу, гүүрэн кран, жиб кран, цахилгаан өргүүр гэх мэт үйлдвэрлэлд зориулагдсан.

БНХАУ-ын Хэнань мужийн Чанюань хотын тогорууны аж үйлдвэрийн бүс