100-ton gantry cranes are widely used in shipyards, steel mills, ports, heavy machinery plants, and large construction sites. They can lift and move heavy objects such as heavy equipment, large components, and containers, and are essential for the efficient handling of heavy materials.

100-ton gantry cranes are a solution for medium-to-large cargo transfers in modern industrial systems. They can easily lift containers and large industrial facility components and are widely used in heavy-load environments such as ports, shipyards, and large construction sites.

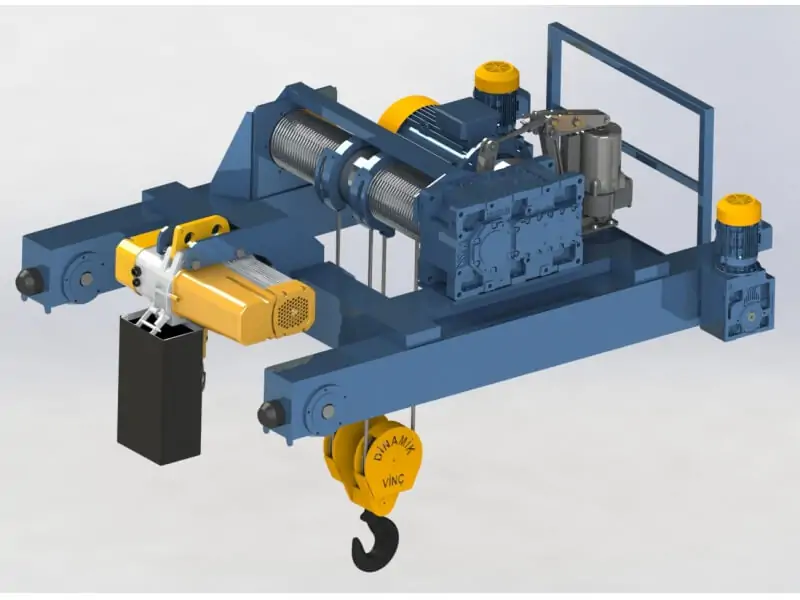

The structural design of the 100-ton gantry crane focuses on the core functions of strong load-bearing capacity, stable operation, and convenient operation . It mainly consists of five parts, which work together to improve the overall operating performance of the crane :

Gantry structure : As the main frame of the crane, it is constructed of high-strength steel and is commonly available in two types: truss and box-type. The truss structure is lightweight and offers excellent wind resistance, making it suitable for windy outdoor environments . The box-type structure offers greater rigidity and load-bearing capacity, making it suitable for heavy-duty operations requiring extreme stability. The outriggers on both sides of the gantry provide stable support for the entire structure. Some models can be designed with a cantilevered gantry to further expand the operating range.

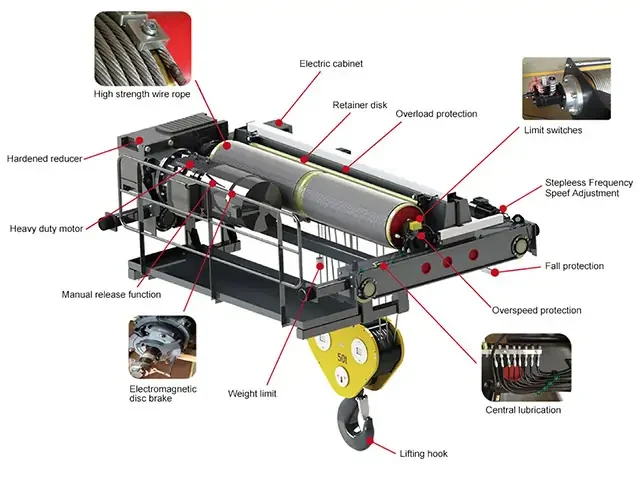

Trolley mechanism :Mounted on the gantry crossbeam, it drives the hook along the crossbeam, enabling horizontal transfer of heavy loads. The mechanism utilizes high-precision guide rails and drive units for high precision and low noise, enabling precise transport of heavy loads to the designated location.

Track system :This mechanism drives the entire crane along the ground track, determining the crane's operating range. The trolley mechanism of rail-mounted cranes utilizes dedicated rails for stable operation and precise positioning. Tire-mounted cranes, equipped with high-strength rubber tires, eliminate the need for fixed rails, allowing for flexible adjustment of operating positions to accommodate temporary or changing operating scenarios.

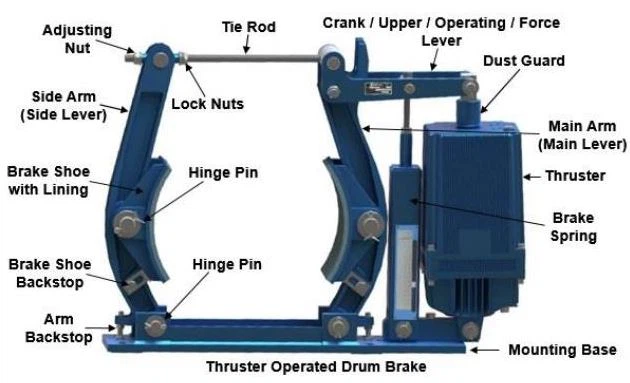

Braking system : This component ensures operational safety . It is used to control the lifting mechanism , the start and stop, and the deceleration during track operation, preventing the load from sliding or the equipment from shifting due to inertia, and reducing safety hazards.

Control systems : There are two types of control systems: cab control and ground remote control. The cab is typically located in a well-viewed area and is equipped with operating handles, an instrument panel, and safety control buttons, allowing the operator to directly observe the operation and precisely control the equipment . Ground remote control allows the operator to control the equipment from a safe distance, making it particularly suitable for flexible operation in complex working environments . Both control methods can be selected or combined based on actual needs.

Application Scenarios Of 100-Ton Gantry Crane

their powerful load-bearing capacity and flexible adaptability, 100-ton gantry cranes play a vital role in modern industry and logistics. At ports and container terminals, they efficiently handle container loading and unloading between ships and transport vehicles, improving cargo turnover . 100-ton cranes are also used in shipyards , precisely lifting heavy components such as hull sections and large engines, making component positioning and installation during shipbuilding and repair more stable and simple. In heavy machinery plants, they can transport large machine tools, heavy castings, and other equipment, reducing labor costs and operational risks, and improving production efficiency . At large-scale construction sites, such as bridge construction and factory building construction, they can also lift heavy building materials such as prefabricated beams and steel frames to ensure projects proceed on schedule . For special needs such as windy outdoor environments and temporary operations , structural components can be adjusted to suit specific scenarios.

| Parameter Category | Parameter range |

| Нэрлэсэн өргөх хүчин чадал | 100 tons |

| span | 10-50 meters |

| Өргөх өндөр | 5-35 meters |

| Гүйлтийн хурд | Lifting speed: 0.8-1 m/min |

| Trolley running speed: 10-12 m/min | |

| Trolley running speed: 13-15 m/min | |

| Applicable temperature | -25℃-40℃ |

| Control method | Cab control, ground remote control |

| Power specifications | 380V , 50Hz , 3-phase AC |

The above parameters are for reference only. If you have special requirements, you can contact us for more detailed customization.

Nucleon is a professonial gantry crane manufacturer with over 20 years of experience. Our гүүрэн кран have been sold to over 60 countries and regions worldwide. If you require a 100-ton gantry crane, please contact us. We will dispatch a team of professional engineers to assist you and provide you with the most suitable service.

Yes. Due to differences in site size, material properties, and operational requirements across different operating scenarios, 100-ton gantry cranes can be customized based on customer-provided parameters (such as span, lifting height, applicable environment, and special lifting equipment requirements). This includes structural adjustments, the addition of functional modules, and safety device upgrades to ensure the equipment is fully compatible with actual operational needs.

Operators must hold the corresponding special equipment operation qualification certificate and be familiar with the structural principles, operating procedures and safety regulations of the equipment; they must receive professional training before taking up their posts and master the operating skills such as equipment startup, operation, shutdown and emergency response; during operation, they must strictly operate in accordance with the rated load of the equipment, and overload operation is prohibited. At the same time, they must pay attention to the operating status of the equipment and shut down the equipment for inspection in time if any abnormality is found.

Conventional models are suitable for environments with temperatures between -25°C and 40°C, are non-corrosive, and free of flammable and explosive gases. If the equipment needs to be used in harsh environments (such as highly corrosive chemical sites, cold and low-temperature regions, and dusty mining scenarios), special protective designs can be customized, such as adding anti-corrosion coatings, low-temperature heating devices, dust filtration systems, etc., to ensure stable operation of the equipment in special environments.

Under normal use and regular maintenance, the average equipment lifespan is 15-20 years. This lifespan is affected by operating frequency, load conditions, maintenance quality, and environmental factors. Long-term overload operation or lack of maintenance can shorten the lifespan. Conversely, standardized operation and high-quality maintenance can effectively extend the equipment's lifespan.

Check the hook and wire rope: Check whether the hook has cracks or wear, and whether the wire rope has broken wires, rust, or looseness. If the hook is found to be worn beyond the standard or the number of broken wires in the wire rope reaches the safety limit, it needs to be replaced immediately.

Check safety devices: Test whether the overload protection device, limit switch, and emergency stop button are working properly to ensure that the safety devices are sensitive and reliable and there are no fault alarms.

Check the electrical system: check whether the cables and terminals are damaged or loose, whether the cab instrument panel display is normal, whether the motor startup sound is smooth, and whether there is any abnormal noise or leakage.

Lubrication and Maintenance: Add specialized lubricant to transmission components such as motors, reducers, and wheel bearings to reduce mechanical wear and ensure smooth operation of the transmission system . Lubrication intervals should be adjusted based on the frequency of equipment operation; high-frequency operations require shorter lubrication intervals.

Structural inspection: Check the bolts connecting the door frame, beams, legs and other structural components for looseness and cracks in the welds . If loose bolts are found , tighten them immediately. If weld cracks are found , contact a professional to repair them to prevent structural deformation or breakage.

Track maintenance: Clean debris and dust from the track surface, check for deformation and offset, and check whether the track joints are flat . If the track is deformed, it must be corrected in time to ensure smooth operation of the trolley and avoid jamming .

Comprehensive testing: Invite professional technicians to use testing equipment to conduct a comprehensive test of the equipment's structural strength, motor performance, and electrical control system, evaluate the equipment's overall operating status, and identify potential faults and hidden dangers.

Parts Replacement:Replace components that have been in use for a long time and have degraded performance , such as aging cables, severely worn wheels, and failed sensors , to ensure that all components of the equipment are in good working condition.

Record archiving: Establish equipment maintenance files, record in detail the annual overhaul test results, replacement parts list, maintenance content, etc., to provide reference for subsequent maintenance and facilitate tracking of equipment operation history and failure patterns.

Corrosive environment: Perform anti-corrosion treatment on the surface of the equipment structure and electrical components every month, clean up the corrosion residues, and reapply the anti-corrosion coating to prevent the equipment from being damaged by corrosion.

Low-temperature environments: Before winter arrives, check that the low-temperature heating device is functioning properly and replace the lubricant with one suitable for low-temperature environments to prevent it from solidifying and affecting the operation of the transmission system . After operation, promptly clean ice and snow from the surface of the equipment to prevent damage to components caused by icing.

Dusty environment : Clean the dust inside the motor, radiator, and electrical cabinet weekly to prevent dust accumulation from affecting equipment heat dissipation or causing electrical short circuits. If necessary, install dust covers on the equipment to reduce dust intrusion.

Өргөх тогорууны мэргэжлийн ханган нийлүүлэгч нь гүүрэн тогоруу, гүүрэн кран, жиб кран, цахилгаан өргүүр гэх мэт үйлдвэрлэлд зориулагдсан.

БНХАУ-ын Хэнань мужийн Чанюань хотын тогорууны аж үйлдвэрийн бүс