Electric hoists are essential electric lifting equipment used in construction sites, warehouses, workshops, and other environments. They enable safe and efficient lifting, lowering, and moving of heavy objects, relying on a coordinated set of mechanisms. The following article will detail their working principles, along with key components and the characteristics of different types.

Parts Of Electric Hoist

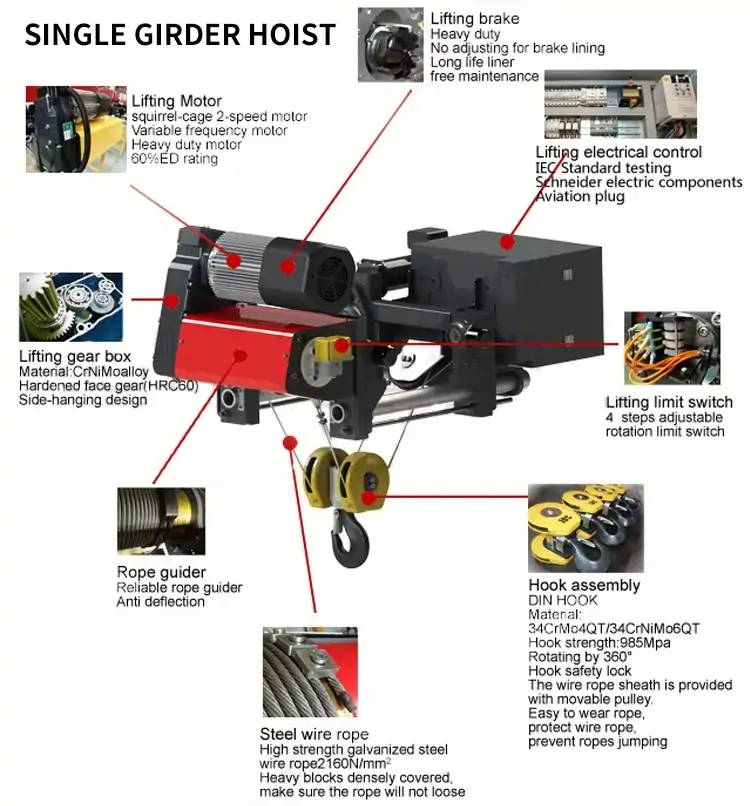

Before delving into the working principles of electric hoists , it's important to first understand the key components that support their operation . Electric hoists generally consist of a motor, a reducer, a brake, a lifting medium, and a control system. These components work together to perform their respective functions.

Electric motor : The power source of the electric hoist , which can convert electrical energy into mechanical energy and then drive the entire system.

Reducer : Converts the high-speed rotation of the motor into the slow-speed rotation required by the drum or sprocket, while increasing the torque to have enough force to lift heavy objects .

Brake : It fixes the weight in place when the electric hoist stops working . It is generally divided into electromagnetic brake and mechanical brake . The brake of the electric hoist is usually composed of brake pads, springs, brake wheels and other components.

Lifting medium :

- Wire rope electric hoist : It carries the weight of the cargo by winding a wire rope made of multiple strands of high-strength steel wire on the drum .

- Electric chain hoist : uses sprocket to drive load chain to lift materials .

Control system : The control box is the control center of the electric hoist, which usually consists of switches, buttons, fuses and other parts.

Working Principle

Electric hoists should strictly comply with regulations to ensure personnel safety and efficient operation of equipment.

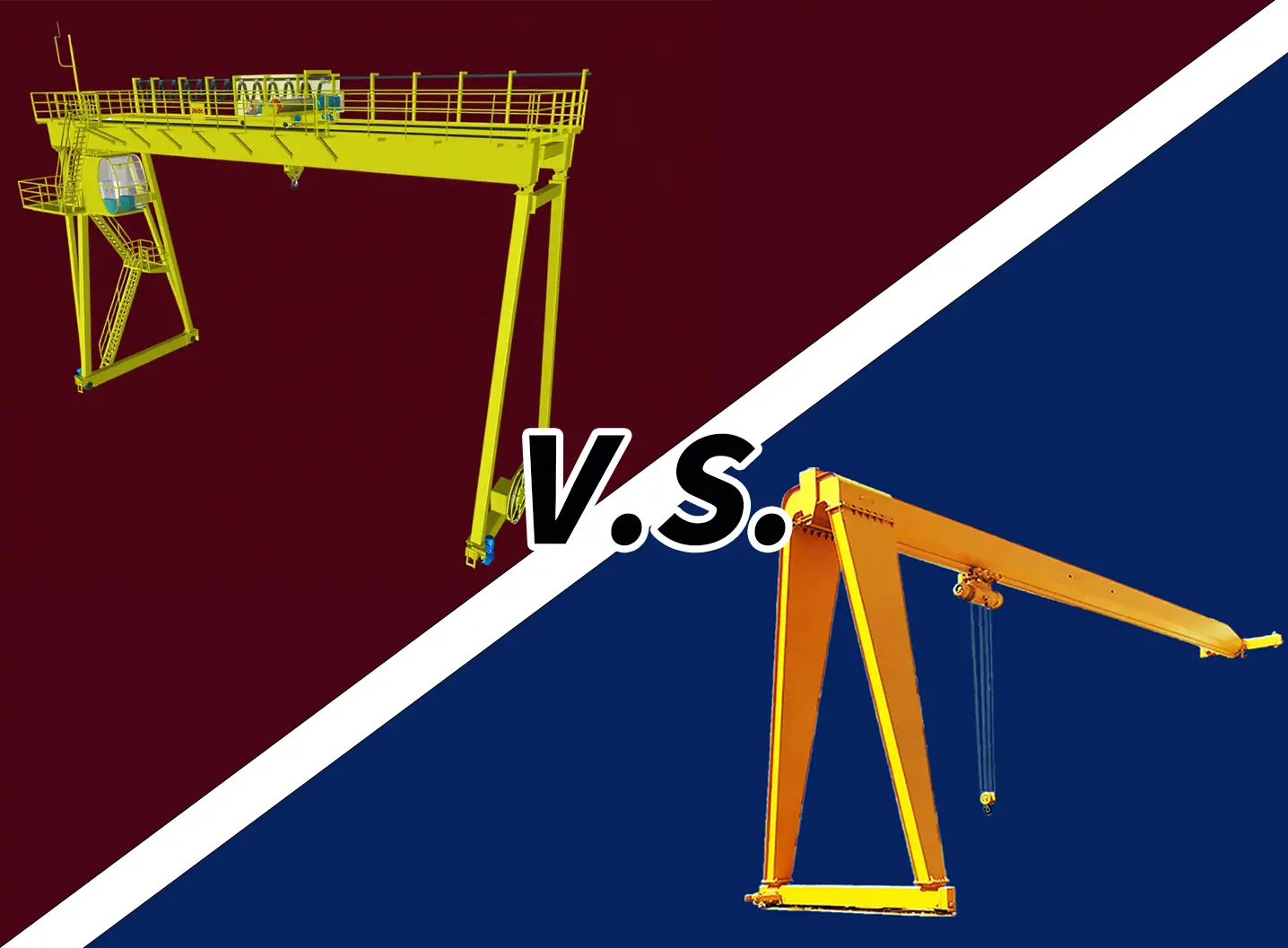

Installation and preparation : First install the electric hoist on a stable load-bearing structure, which is generally used in gantry cranes and bridge cranes.

Power on and brake release : After the operator starts the control system, the motor is powered on and the brake is released at the same time .

The reducer transmits torque : The high-speed rotation of the motor is transmitted to the reducer, which reduces the speed and amplifies the torque through the coordination of gears with different numbers of teeth inside, making it sufficient to lift heavy objects.

Lifting medium operation : Wire rope hoists and electric chain hoists operate differently.

- Wire rope hoist: Through the rotation of the drum, the wire rope is evenly wound under the guidance of the rope guide, and at the same time, the heavy object on the hook is lifted.

- Electric chain hoist: The sprocket rotates, pulling the load chain upward, and the excess chain is stored in the chain bag .

Cargo positioning : When the material reaches the target height, the control system stops the motor, the brake will engage, and the drum or sprocket will be locked to fix the height of the material .

Types Of Electric Hoists

Different types of electric hoists are designed for different specific needs and therefore have many differences.

Electric chain hoist

Core features: Closed-loop load chain as lifting medium, compact structure, light weight; equipped with electromagnetic brake (fast braking response), multiple limit switches and overload protection.

Advantages: High flexibility in narrow spaces, wear-resistant chains (mostly made of heat-treated steel), low maintenance costs; strong adaptability to dusty and humid environments, suitable for light and medium-duty lifting in workshop assembly, small warehouses, etc.

CD/MD Electric Hoist

Core features: Single-speed electric hoist model, only one regular lifting speed . Simple structure , small size, easy installation and maintenance.

Advantages: High operating efficiency, low cost, suitable for simple lifting scenarios without special requirements for speed and accuracy.

European Electric Hoist

The European-style electric hoist utilizes a lightweight, finite element-optimized design, boasting a light weight, compact structure, and minimal footprint, effectively improving plant space utilization and lifting height. Compliant with international standards such as FEM/DIN, it features dual brakes, overload protection, dual limit stops, a wire rope anti-loosening design, variable frequency drive, smooth starting and stopping, precise positioning, and effective load swing suppression, making it ideal for precision lifting applications. Remote control is supported, along with data monitoring and remote management, making it ideal for smart factories.

Дүгнэлт

Electric hoists are key components for many types of cranes, efficiently increasing material handling speed. They are also widely used in the logistics and chemical industries. If you are interested in electric hoists, please contact Nucleon. Our team of professional engineers is eager to provide you with high-quality, cost-effective service.