Il paranco elettrico per la metallurgia della serie YH è un'apparecchiatura di sollevamento ad alta sicurezza progettata per il sollevamento di metalli fusi, ampiamente utilizzata nell'industria metallurgica. È dotato di molteplici funzioni di protezione di sicurezza, come il doppio sistema di frenatura, la doppia protezione di limite e la piastra di isolamento termico. Queste funzioni garantiscono un funzionamento stabile in ambienti metallurgici ad alta temperatura e ad alto rischio.

YH series metallurgy electric hoist is a high-safety lifting equipment designed for lifting molten metal working conditions, widely used in the metallurgical industry. It is equipped with multiple safety protection functions such as a double braking system, double limit protection, and a heat insulation plate. These functions ensure stable operation in high-temperature and high-risk metallurgical environments.

Questo paranco per la metallurgia si abbina di solito al carroponte metallurgico a una sola trave di tipo LDY, oppure è installato in modo indipendente nell'officina, fissato sotto la rotaia di sospensione; è un'apparecchiatura di sollevamento metallurgica leggera, altamente efficiente e flessibile, in grado di soddisfare una varietà di esigenze di sollevamento nell'officina metallurgica.

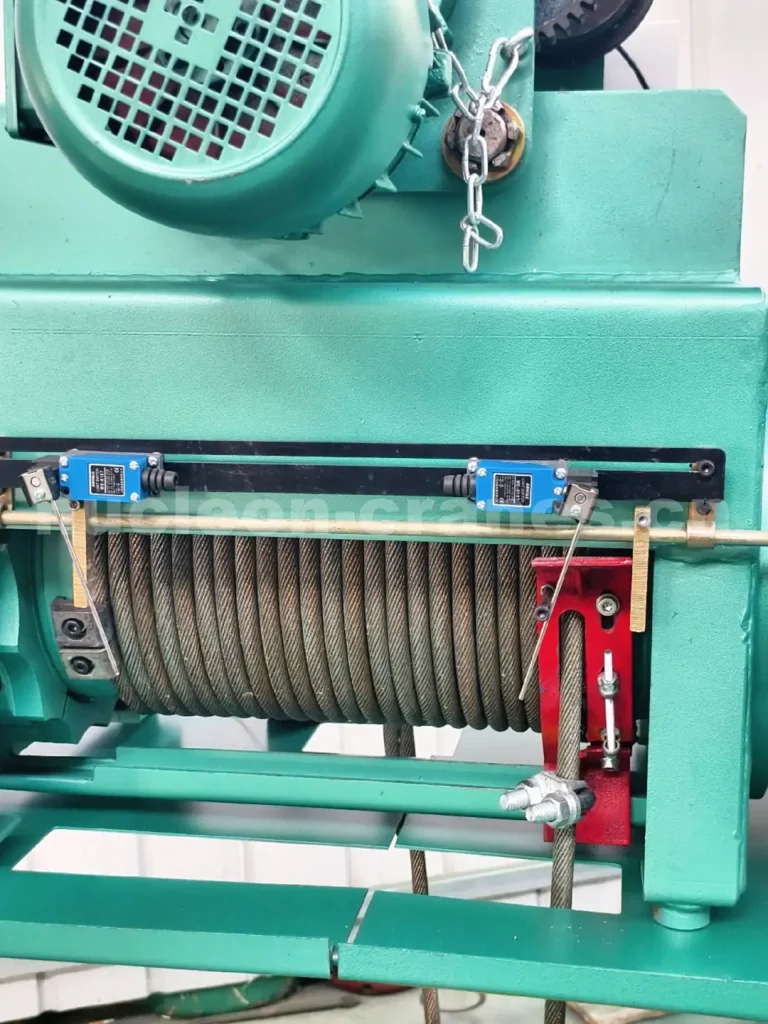

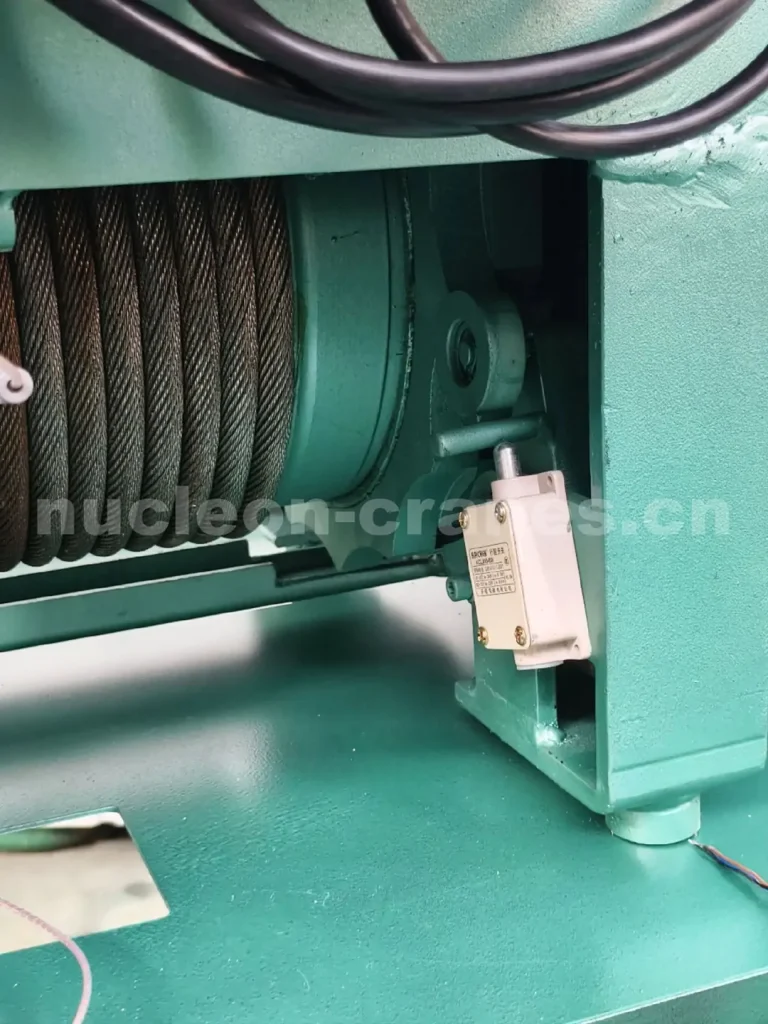

Il paranco elettrico a fune di tipo YH per la metallurgia è ottimizzato sulla base della tecnologia matura di Paranco elettrico a fune tipo CD1/MD1, and upgraded for the special working condition of lifting molten metal. A set of independent safety brakes is added to the drum to further enhance the safety and reliability of the equipment, which is in full compliance with the high standard requirements for lifting equipment in the metallurgical industry.

Metallurgical hoists are primarily categorized into two types:

The CD-type electric hoist features a single-speed design with a simple structure, offering a lifting speed of 8 meters per minute, making it suitable for standard lifting operations.

The MD-type electric hoist features a dual-speed design, offering two speed options: 8 meters per minute and 0.8 meters per minute. The low-speed setting enables precise positioning functionality, making it particularly suitable for applications requiring fine control, such as machine tool installation and equipment maintenance. The dual-speed design allows the MD-type hoist to maintain conventional lifting capacity while significantly enhancing operational precision and safety, thereby meeting the requirements of precision loading/unloading, sandbox clamping, and other fine-tuning tasks.

YH metallurgical electric hoists are specially designed for lifting molten metal and are suitable for industrial environments such as foundries, metallurgical workshops, and sand casting workshops. They are typically operated using a wireless remote control. To ensure safety and reliability, they must not be used in areas with explosion hazards, where sulfuric acid or other corrosive gases are present, or in environments where toxic or flammable items are being lifted.

| Specifiche del modello | HY1T | HY2T | HY3T | HY5T | HY10T | ||

| Altezza di sollevamento | contatori | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 9/12/18/24/30 | |

| Velocità di sollevamento (/lento) | m/min | 8 | 8 | 8 | 8 | 7 | |

| Velocità di corsa | m/min | 20 | 20 | 20 | 20 | 20 | |

| fune metallica | Diametro della corda | mm | 7.4 | 11 | 13 | 15.5 | 15.5 |

| Diametro del filo | mm | 0.34 | 0.5 | 0.6 | 0.7 | 0.7 | |

| forma strutturale | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | ||

| Binario a I modello GB706-65 | 16-28b | 20a-32c | 20a-32c | 25a-45c | 32b-63c | ||

| Grado di lavoro | M6 | M6 | M6 | M6 | M6 | ||

| Modello | YZD 22-4 | YZD 31-4 | YZD 32-4 | YZD 41-4 | YZD 51-4 | ||

| Motore di sollevamento | capacità | kW | 1.5 | 3 | 4.5 | 7.5 | 13 |

| NUMERO DI GIRI | giri al minuto | 1380 | 1380 | 1380 | 1380 | 1380 | |

| Numero di fasi | 3 | 3 | 3 | 3 | 3 | ||

| Tensione | Volt | 380 | 380 | 380 | 380 | 380 | |

| Attuale | Ampere | 4.3 | 7.6 | 11 | 18 | 30 | |

| Frequenza | Settimane/Secondi | 50 | 50 | 50 | 50 | 50 | |

| Modello | YZD 12-4 | YZD 12-4 | YZD 12-4 | YZD21-4 | YZD21-4 | ||

| Motore in funzione | capacità | kW | 0.4 | 0.4 | 0.4 | 0.8 | 0.8 |

| NUMERO DI GIRI | giri al minuto | 1380 | 1380 | 1380 | 1380 | 1380 | |

As a professional manufacturer of YH-type metallurgical electric hoists, Nucleon leverages its robust technical capabilities and extensive industry experience to provide customers with high-quality, highly reliable metallurgical lifting equipment. We not only provide standard models of metallurgical wire rope electric hoists but also offer customized design and production based on your specific requirements, including non-standard metallurgical electric hoists and casting-specific electric hoists, with a complete range of specifications to meet diverse operational needs.

From R&D and design, production and manufacturing, to transportation, installation, commissioning, testing, and operator training, we offer a comprehensive turnkey engineering service, effectively reducing your procurement and management costs.

If you have any procurement or customization needs for metallurgical electric hoists, please feel free to contact us! Our professional team will provide you with the optimal solution.

Fornitore professionale di gru di sollevamento, dedicato alla produzione di gru a ponte, gru a cavalletto, gru a bandiera e paranchi elettrici, ecc.

Zona industriale della gru, città di Changyuan, provincia di Henan, Cina