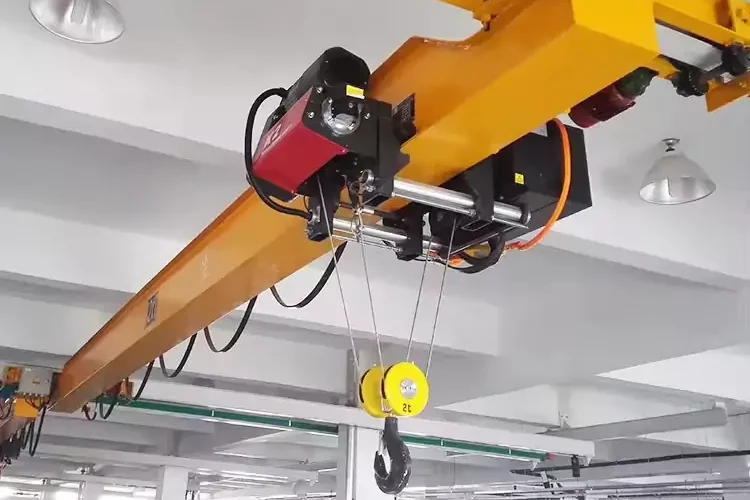

The single girder eot crane is a practical industrial handling equipment with a simple structure. It uses a single main beam structure with end beams and electric hoists to achieve flexible handling of heavy objects. It is widely used in small and medium-sized industrial sites to handle medium and light materials.

Single Girder eot crane is high efficiency equipment for industrial material handling, renowned for their simple structure and practical performance. They utilize a single main girder structure with end beams and a hoist trolley to enable vertical lifting and horizontal transfer of heavy loads. Single Girder EOT cranes are widely used in small and medium-sized warehouses, workshops, assembly lines, and other locations, providing reliable support for light to medium-load material handling.

We offer a different types of Single Girder EOT Cranes, including European type, grab bucket type, underslung type, and more, to meet specific lifting and operational needs. Whether you require high precision, bulk material handling, or space-saving designs, our engineering team can provide customized solutions based on your working environment, load capacity, and production requirements.

The Single Girder EOT Crane crane meet the strictest European safety and design standards and typically utilize a modular design, offering superior structural strength, safety features, and energy efficiency. They offer high operational stability and low noise levels, making them suitable for high-end industrial applications such as precision manufacturing and automotive production, where safety and environmental performance are paramount. Core Structure and Advantages.

The Grab Bucket EOT crane utilize a single girder structure equipped with a grab bucket. They are suitable for handling bulk materials such as ore, grain, and coal. They are commonly used in ports, mines, and warehouses. The grab bucket opens and closes for rapid loading and unloading, improving bulk cargo handling efficiency.

The cranes feature a single girder structure suspended from overhead I-beams. They are ideal for space-constrained environments like compact workshops and small warehouses. Without needing ground supports, they save floor space significantly. Equipped with electric hoists, they enable flexible lifting and lateral movement of light to medium loads , enhancing efficiency in material handling for assembly lines, pump rooms, and pharmaceutical facilities. Explosion-proof versions are available for hazardous areas.

Main Girder: A single box-type or beam-type main girder serves as the core load-bearing structure. Compared to double-girder eot cranes, this crane prioritizes lightweight construction and is suitable for shorter span operations.

End Beams: Traveling devices at each end of the main girder support the crane along the track, ensuring smooth movement.

Hoist and Trolley: The electric hoist uses steel ropes to raise and lower loads, while the trolley drives the hoist along the main girder, enabling precise vertical and horizontal handling.

Cost-Effectiveness: Compared to double-girder cranes, this crane boasts a simpler structure, lower manufacturing and installation costs, making it suitable for businesses with limited budgets.

Space Compatibility: Its compact design saves space and is particularly suitable for small and medium-sized workshops or environments with height restrictions.

Flexible Operation: The coordinated operation of the hoist and trolley allows for rapid lifting, transfer, and positioning of materials, improving operational efficiency of the EOT crane.

Light Industrial Workshops: Suitable for handling lightweight cargo such as parts and finished product boxes in industries such as electronics and food processing.

Warehouse Logistics: Stacking and loading and unloading goods within the warehouse, combined with racking systems to improve storage utilization.

Assembly Line: Provides material supply to the assembly line and assists in component handling during product assembly.

Maintenance Shop: Used for lifting components during equipment overhaul, facilitating maintenance work.

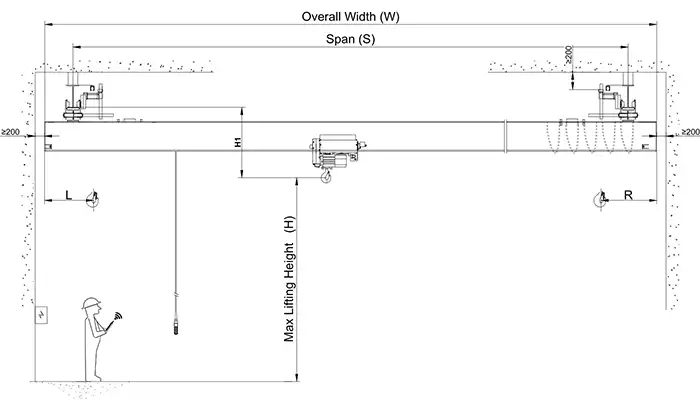

Please refer to the information below to provide accurate technical specifications for the Single Girder EOT Crane, which will assist our engineering team in designing the most suitable solution tailored to your needs.

Get your customized crane solution today, send project details to our company, and we will provide professional advice.

Nucleon is a leading manufacturer and supplier of single-girder EOT cranes in China, offering a comprehensive product range that includes European standard, suspended, and low-headroom configurations. With over 20 years of R&D and manufacturing experience, state-of-the-art production facilities, and a team of professional engineers, we provide customized design solutions tailored to meet our customers' specific requirements. We specialize in efficient, low-maintenance, and reliable systems designed to optimize material handling and enhance operational efficiency across various industries. For customized single-girder bridge cranes, please contact us immediately to receive tailored solutions and accurate quotes.

The full form of EOT crane is Electric Overhead Traveling crane. It refers to cranes that are electrically powered and travel along overhead rails, commonly used in industrial settings for lifting and moving heavy loads.

The difference between single-girder cranes and double-girder cranes mainly lies in their structure, load-bearing capacity and applicable scenarios: single-girder cranes have only one main beam and relatively weak load-bearing capacity, and are suitable for light-load and low-headroom working environments; while double-girder cranes have two parallel main beams and stronger load-bearing capacity, and are more suitable for heavy-load and high-precision operation requirements.

The lifting capacity of a single-girder crane is usually between 0.5 tons and 20 tons, but some specially designed models can reach a lifting capacity of 32 tons. However, the specific lifting capacity is generally determined according to customer needs.

Fornitore professionale di gru di sollevamento, dedicato alla produzione di gru a ponte, gru a cavalletto, gru a bandiera e paranchi elettrici, ecc.

Zona industriale della gru, città di Changyuan, provincia di Henan, Cina