Gantry cranes are essential equipment for outdoor cargo yards, ports, construction sites, and large warehouses. Their ability to lift heavy loads in open spaces makes them essential equipment for these applications. Their stable operation relies on a suite of coordinated gantry crane parts, each performing a specific function. Understanding these parts is crucial for equipment maintenance, safe operation, and optimal performance. In this article, we will explore the core parts of gantry cranes.

Mast

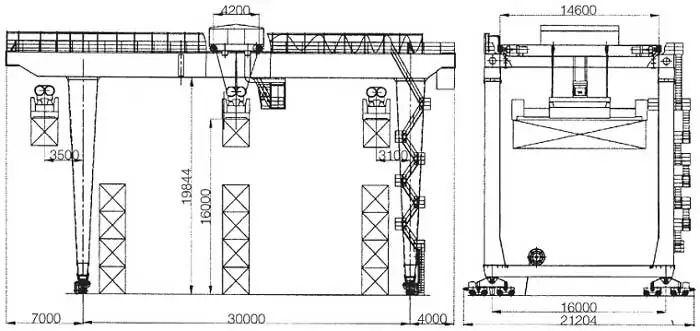

The gantry is the gantry crane's primary load-bearing structure and a key part. It forms the crane's iconic "inverted U-shape," eliminating the need for overhead rail support like bridge cranes. Composed of two vertical legs connected by a horizontal main beam, it forms a stable framework to support other parts. Designed to withstand heavy loads, the outdoor environment, and the dynamic forces of operation, the gantry crane comes in three common types: full gantry, semi-gantry, and mobile gantry, each suited to different operational needs.

Outriggers and running mechanisms

The outriggers are the vertical parts of a gantry crane, supporting the main girder and connecting the gantry to the ground. The operating mechanism is the core part of the outriggers, driving the entire crane along its operating path. Each outrigger houses wheels, a motor, and a transmission system, powering the crane's longitudinal movement along the ground track. Outriggers are typically equipped with reinforced diagonal braces for enhanced stability, particularly in locations susceptible to strong winds. They are also equipped with buffers and limit switches to prevent collisions with track end blocks or other equipment.

main beam

The main beam spans horizontally between the two legs. It is a key gantry crane part that provides a running track for the trolley and carries heavy objects for hoisting. Its design directly determines the span load-bearing capacity of the crane. Steel beam structures are mostly used. Box beams are a common choice due to their strong rigidity and high strength. They must have sufficient bending strength to avoid deformation under heavy loads and ensure smooth movement of the trolley. Large gantry cranes often have inspection walkways or platforms on their main beams to facilitate maintenance operations.

Carrello

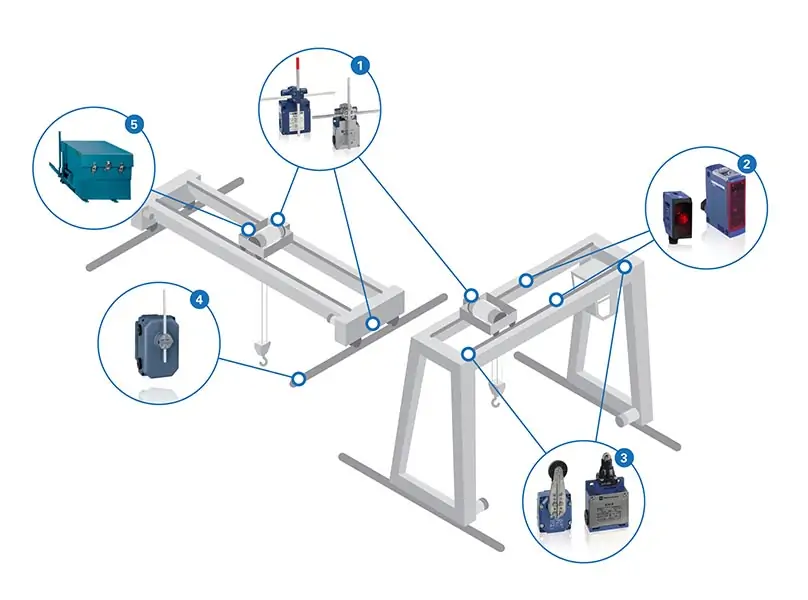

The trolley is a movable part of the gantry crane. It travels along the main beam track and can drive the winch and heavy objects to achieve lateral movement. It consists of a frame, wheels and a transmission system. The transmission system can drive the trolley to move along the main beam track. It is also equipped with limit switches. When the trolley travels to both ends of the main beam, it will automatically stop to prevent derailment. The design must match the load-bearing capacity of the winch to ensure balanced load distribution and avoid tilting during operation.

hoist

The winch is responsible for raising, lowering, and suspending loads in a gantry crane. As a key lifting part, it works in conjunction with the trolley to precisely position the load. It primarily consists of a motor, drum, lifting medium, and hook assembly. It features an overload limiter to prevent overloading and a fall arrester to prevent the load from falling if the lifting medium breaks. Common types include electric and hydraulic winches, some with speed regulation for smooth lifting and lowering.

operating system

The operating system is used to control all movements of the gantry crane and coordinate the work of the operating mechanism, trolley and winch. It is a key gantry crane part to ensure safe and precise operation. It has various control methods, including a suspended button box, wireless remote control and cab control, which can meet the needs of different operating scenarios. The operating system is also linked with the safety system to automatically cut off operation in an emergency to ensure the safety of equipment and personnel. Some models are also equipped with a variable frequency drive to achieve smooth acceleration and deceleration, reduce load shaking, and reduce equipment structural stress.

Safety devices

Safety devices are special gantry crane parts that ensure the safety of operators, equipment and loads. They cover a variety of protective components, including an overload limiter that can detect load weight and trigger an alarm or shutdown when the limit is exceeded; a buffer block that can absorb impact energy to reduce collision damage when the crane or trolley reaches its operating limit; an emergency stop button that can immediately cut off power to all systems and terminate operations in an emergency; and an anti-collision system that can prevent collisions between equipment or between equipment and obstacles when multiple cranes work together.

Ending

Familiarity with the characteristics and functions of gantry crane parts is not only essential for proper equipment maintenance and stable operation, but also ensures better adaptability to the operational demands of diverse industrial scenarios, allowing gantry cranes to continue to deliver on their core value in heavy-lifting. For part replacement or customization needs, contact Nucleon. Our professional engineers will provide you with high-quality, cost-effective customization services.