Gantry cranes are essential equipment in today's industrial construction, significantly improving material handling efficiency. Gantry cranes also come in various structural variations. Choosing the right crane not only improves production efficiency but also ensures better worker safety. This article provides basic information on full gantry cranes and semi-gantry cranes to help decision-makers select the most suitable crane.

Structural design

Full Gantry cranes

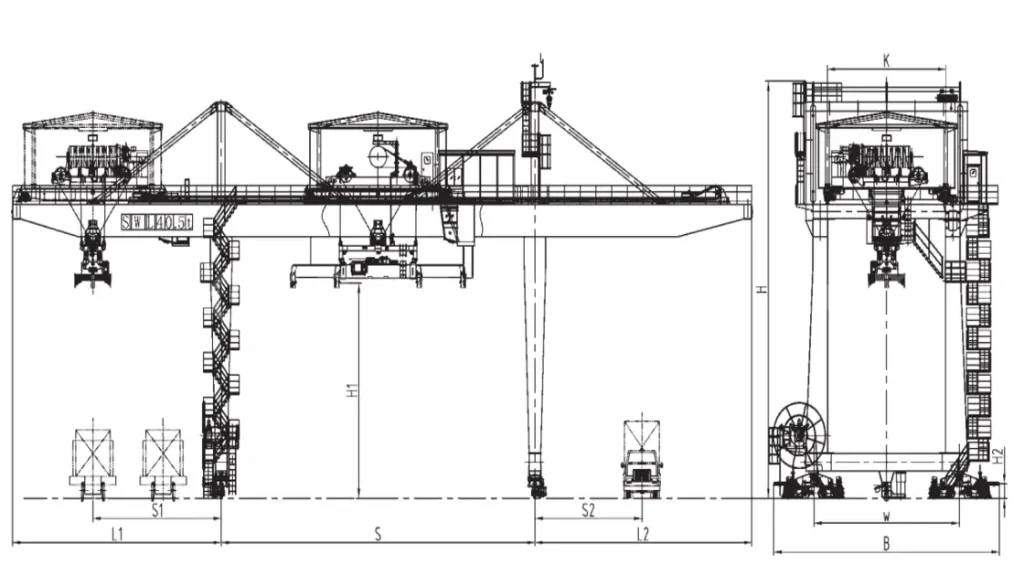

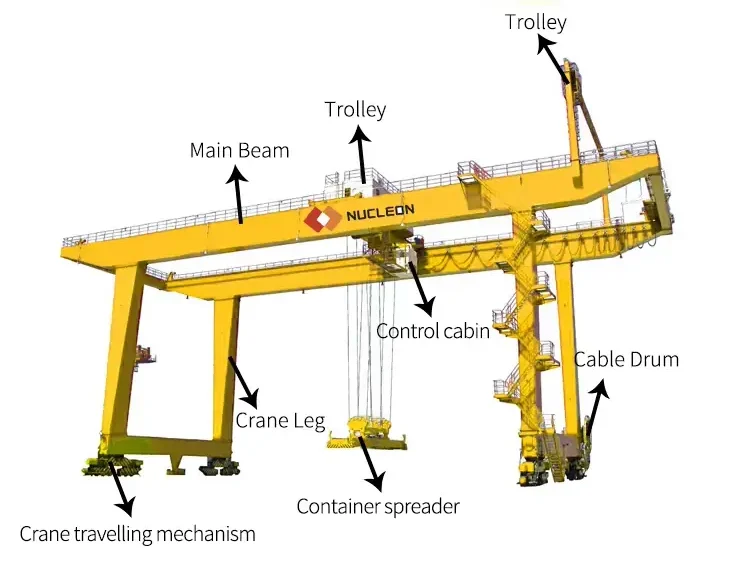

Full gantry cranes, or rail-mounted gantry cranes, feature a full-gantry structure with outriggers supporting a crossbeam on both sides. They move along fixed tracks on the ground using wheels. Equipped with specialized lifting gear, they offer a robust overall structure suitable for handling heavy loads and are commonly found on large outdoor work sites.

Semi-gantry crane

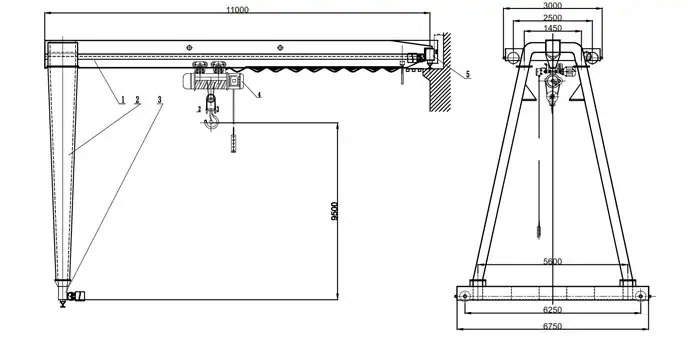

Semi-gantry cranes utilize a hybrid support structure, with one end running on ground tracks via outriggers, while the other end utilizes existing building structures such as plant columns, walls, or fixed overhead rails to support the crossbeam. This compact design allows for flexible adaptation to diverse site conditions and is primarily used in indoor or semi-indoor environments.

Crane features

Full Gantry cranes

Advantage

lifting capacity , it can easily handle heavy and even ultra-heavy loads and meet the needs of large cargo handling.

It runs stably, moves along a fixed track, has high operating precision, and can accurately complete the loading, unloading and stacking of goods.

It has strong scalability and can be equipped with advanced control systems to improve the degree of automation, realize remote operation and intelligent management, and improve work efficiency.

Shortcoming

The installation cost is high, and special tracks need to be laid, which requires a large initial investment.

The range of movement is limited and it can only run along the track, and the working area cannot be flexibly adjusted.

It has high requirements on the site, requiring a large open space to accommodate the structure and running track of the full gantry crane . It is difficult to achieve high efficiency in small warehouses and narrow sites.

Semi-gantry crane

Advantage

The cost is low, there is no need to lay double tracks, and existing building structures can be used, saving installation and construction costs.

It has high space utilization and compact structure, making it suitable for use in places with limited space such as factories and warehouses.

It has strong adaptability and can be flexibly installed according to the actual situation of the site, and can be well integrated with the existing production layout.

Shortcoming

The lifting capacity is relatively weak, it cannot bear excessively heavy loads, and has certain limitations on its scope of application.

Depends on the supporting structure, and its operational stability is greatly affected by the strength of the building structure it relies on.

The operating speed and efficiency are slightly low, and it performs poorly in high-intensity, high-frequency operation scenarios.

Factors to consider when choosing

Working load : If you need to carry heavy goods, it is preferred Full gantry cranes with greater lifting capacity . If you mainly handle light to medium loads, semi-gantry cranes are more suitable.

Site conditions : In open, large outdoor areas, the advantages of Full gantry cranes' tracks can be fully utilized. In indoor or semi-indoor environments with limited space, semi-gantry cranes are more suitable.

Cost : If you have a sufficient budget and need to perform heavy-duty operations over a long period of time, an full gantry crane is the right choice . If you have a limited budget or are looking for economy, a semi-gantry crane is a better choice.

Operational efficiency : For scenarios requiring high-frequency, high-efficiency operations, full gantry cranes are more suitable . When the operation pace is slow, semi-gantry cranes are more suitable .

Site flexibility : Full gantry cranes are suitable for applications where the work area is fixed and does not require frequent adjustments . Semi-gantry cranes are more advantageous when the site layout may change or flexibility is required to adapt to different areas.

Conclusione

Cranes vary in many ways, and the key to choosing the right crane is selecting the type that best suits your needs. If you're still unsure about choosing between an Full gantry crane and a semi-gantry crane, contact Nucleon. Our professional team of engineers can develop a customized solution that best meets your needs at a competitive price.