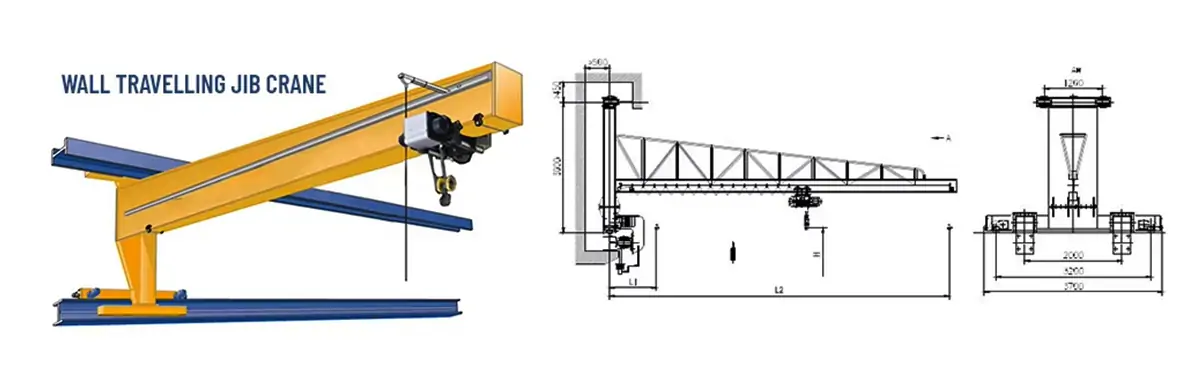

La grue à flèche mobile est basée sur la structure de la grue à flèche de pilastre traditionnelle. Il s'agit d'une sorte de grue à flèche qui peut se déplacer le long d'un mur ou d'une autre structure de soutien sur une voie surélevée.

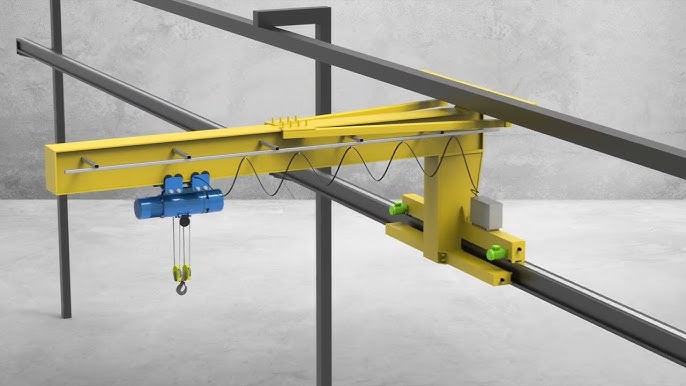

The wall traveling jib crane also called a wall running jib crane, offers a space-saving lifting solution specifically engineered for efficient material handling along walls or elevated structures. Unlike floor-mounted jib cranes, it requires no floor space or concrete foundations, making it particularly suitable for workshops, assembly lines, and warehouses with limited floor clearance. The crane operates smoothly on ASCE rails via an electric wall-travel mechanism, enabling seamless material movement across extended work zones without interfering with overhead crane operations. With a lifting capacity up to 15 tons and customizable span lengths, it delivers operational flexibility for diverse industrial applications.

L'équipement adopte une méthode unique de montage des rails, fixant le rail de déplacement directement sur les colonnes de béton de l'usine, réalisant ainsi un mouvement longitudinal précis le long du rail. Sa fonction principale est complétée par le palan électriquequi peut réaliser simultanément un mouvement latéral le long du porte-à-faux et une opération de levage vertical. Il est particulièrement adapté aux lieux de travail nécessitant une grande couverture, tels que les grands ateliers et les entrepôts.

Wall traveling jib crane is based on the structure of traditional jib crane R & D design, is a kind of jib crane that can run along the wall or other supporting structure on the elevated track.

L'équipement adopte une méthode unique de montage des rails, fixant le rail de déplacement directement sur les colonnes de béton de l'usine, réalisant ainsi un mouvement longitudinal précis le long du rail. Sa fonction principale est complétée par le palan électrique, qui peut simultanément réaliser un mouvement latéral le long du porte-à-faux et une opération de levage vertical. Il est particulièrement adapté aux lieux de travail qui nécessitent une grande couverture, tels que les grands ateliers et les entrepôts.

Wall-traveling jib cranes are used in workshops or warehouses with large spans and high building heights, and are more suitable when lifting operations are frequent near the walls. It can be widely used in factories, mines, workshops, production lines, assembly lines and machine tools, up and down work and warehouses, docks, and other occasions of heavy lifting.

| Capacité de levage | TON | 0.5 | 1 | 2 | 3 | 5 | 10 |

| Hauteur de levage | M | 6, 9, 12, 18, 24, 30 | |||||

| Validité Cantilever | M | 1 | 1.2 | 1.5 | |||

| Système de travail | A3 | ||||||

| Vitesse de levage normale | m/min | 8 | 7 | ||||

| Vitesse de levage lente | 0.8 | 0.7 | |||||

| Vitesse de déplacement du chariot | 20/30 | ||||||

| Vitesse de déplacement de la grue | 8~40 | 2~20 | |||||

| Source d'énergie | 3phases A.C. 50hz 380V ou sur mesure | ||||||

| Température de l'environnement de travail | -20℃~+45℃ | ||||||

| Peut être conçu et produit selon les exigences de la voie de l'usine. | |||||||

Selecting the right jib crane enhances lifting efficiency and ensures workplace safety. Nucleon offers a full range of customizable jib cranes, including column-mounted, mobile, wall-mounted, wall-traveling, and articulated types, to meet diverse industrial environments and material handling requirements.

Contact our expert team to help you select the most optimal, reliable, and cost-effective jib crane solution.

Regardless of the jib crane type you require, our engineering team can recommend suitable models based on your specific needs, handling design, and manufacturing. Lifting capacity, span length, rotation angle, and installation methods are all customizable.

As a professional manufacturer and supplier of Wall Traveling Jib Cranes, we are committed to providing high-quality material handling solutions to customers worldwide. With over 20 years of professional manufacturing experience, our products are constructed using premium-quality steel and precision transmission systems, with a rated lifting capacity ranging from 0.5 to 10 tons and a rotation angle of 180° to 360°. They are particularly suitable for use in space-constrained environments such as workshops, warehouses, and ports.

All products are certified to international standards such as CE and ISO, and can be equipped with optional intelligent features such as variable frequency control and anti-swing functionality. We have a comprehensive export service system, with products exported to over 50 countries and regions worldwide, including Europe, America, and Southeast Asia. For your specific requirements, our engineering team can provide a one-stop customized service from design to installation. For detailed technical specifications or customized quotes, please feel free to contact our sales consultants, and we will provide you with the most competitive solutions.

The primary distinction lies in their structural form and operating mode. Below is a concise comparison:

Fournisseur professionnel de grues de levage, spécialisé dans la fabrication de ponts roulants, de grues à portique, de grues à flèche et de palans électriques, etc.

Crane Industry Zone, Changyuan City, Henan Province, China