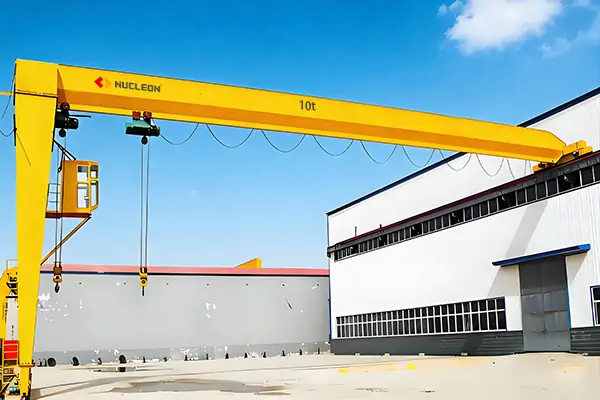

The 10-ton gantry crane is an excellent material handling equipment. Its rated lifting capacity covers most light and heavy cargoes and is widely used in production workshops, warehouses, construction sites, port terminals and other scenarios.

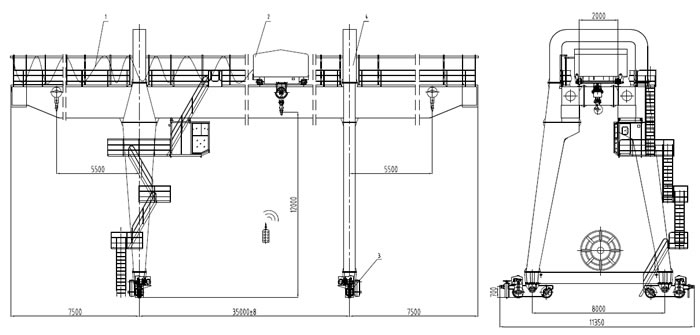

The 10-ton gantry crane is a light to medium-duty lifting equipment, featuring a single or double main beam structure and equipped with an electric hoist as the lifting mechanism. It has a standard lifting height of 3-12 meters, a customizable span, and utilizes a trolley track for horizontal movement of goods. The entire machine is compact, occupies minimal space, and is flexible and easy to operate. It is suitable for workshops, freight yards, small and medium-sized ports, and warehouses, meeting the efficient loading and unloading needs of goods weighing less than 10 tons.

This gantry crane has a simple structure and stable performance, and can be customized with various accessories to meet the needs of industries such as chemical, logistics, construction, and mining. In addition to the single-beam structure, Nucleon also offers various types of gantry cranes, including double-beam, portable, truss, and semi-truss types, to meet diverse application scenarios.

The 10-ton gantry crane consists of the main beam, lifting system, trolley system, operating system, control system and other components, each of which is responsible for different functions of the crane.

Main Beam: The core load-bearing component, usually box-shaped or I-beam shaped. It bears the weight of the cargo, crane, and trolley, ensuring structural stability during lifting and preventing deformation under a 10-ton load.

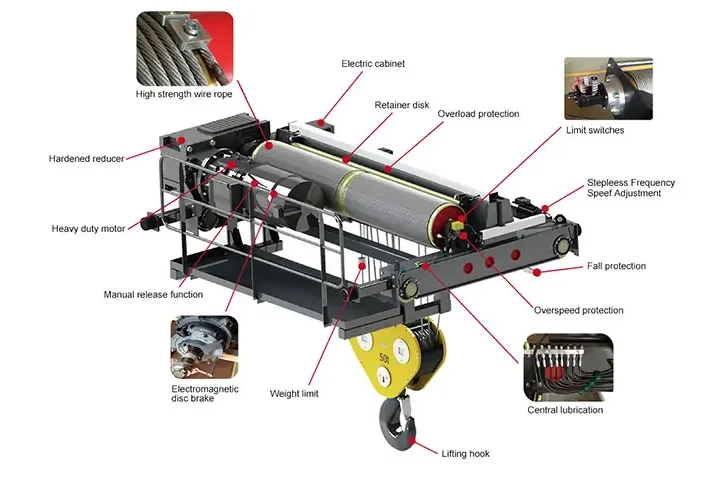

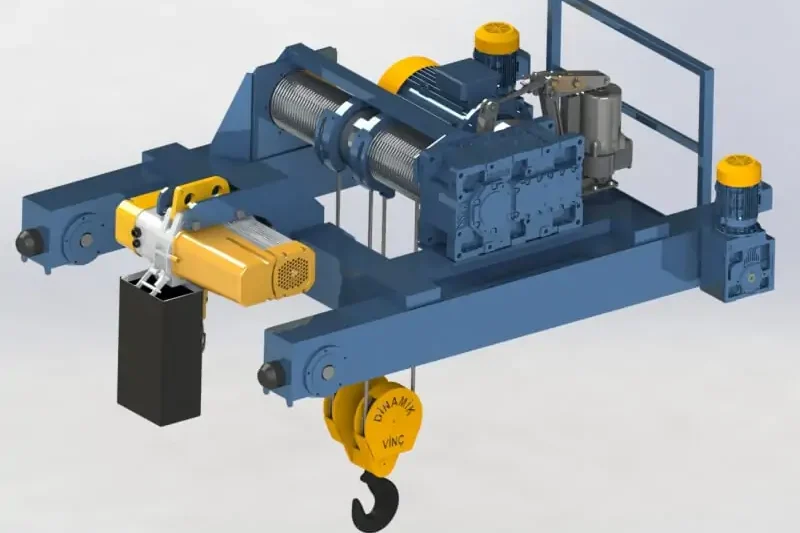

Lifting system : The electric hoist and hook are key parts of the lifting system . The electric hoist provides lifting power, and the hook is used to pick up and place materials.

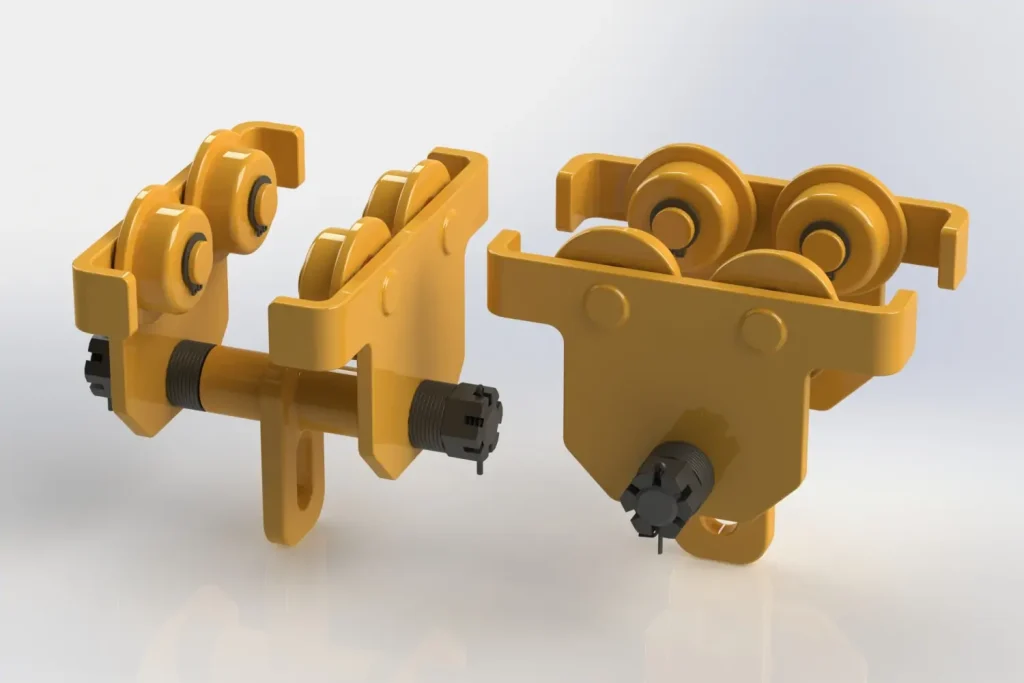

Trolley Traveling Mechanism: Consists of a trolley frame, wheels, and a geared motor. It drives the electric hoist to move along the main beam, thus extending the horizontal working range of the crane.

Crane Traveling Mechanism: Includes wheel sets, drive motors, and brakes. It enables the entire crane to move along the ground rails, facilitating long-distance cargo transportation on large construction sites.

Control System : 10-ton gantry cranes are typically controlled by a wireless remote control and cab . The wireless remote control allows for remote control, ensuring safety and efficiency. A technician can also control the crane from the cab to perform more complex operations.

Our 10-ton gantry cranes are available in a variety of types and configurations, each suited to specific lifting needs and applications. The following are some of the most common types:

Single-girder gantry cranes have a simple structure, light weight, and are easy to install and relocate, resulting in lower initial investment costs. They use an electric hoist as the core lifting mechanism, which runs along the lower flange of the main beam, enabling both vertical and horizontal material handling. The electric hoist is available in two types: wire rope or chain, allowing users to choose flexibly according to their needs.

Caractéristiques

Simple structure: Box-type/I-beam structure, light weight, good rigidity, and convenient installation and maintenance.

Efficient operation: Smooth and flexible ground operation, adaptable to diverse work scenarios.

Economical and practical: Low manufacturing cost, a cost-effective solution for small and medium-tonnage lifting.

Strong compatibility: Supports various electric hoists, including CD, MD, and European standards.

Compact layout: Single main beam design saves space, suitable for environments with height or space limitations.

Applications

Logistics and warehousing: Used for loading, unloading, transferring, and stacking goods in warehouses.

Manufacturing: Serves production lines in workshops, enabling precise material handling and process integration.

Ports and terminals: Performs loading, unloading, and short-distance transportation of containers and heavy bulk cargo.

Construction: Participates in lifting reinforcing steel, precast concrete components, and other building materials.

10-ton-L-type-single-girder-gantry-crane

10-ton-MH-type-single-beam-gantry-crane

10-ton-portable-gantry-crane

The double girder gantry crane is a heavy-duty gantry crane with two parallel girders and an electric trolley that moves along the girders, enabling horizontal material handling. It has two operating modes: ground control and control room operation. The control room is available in open and enclosed types and can be installed on the left or right side depending on the actual situation.

Caractéristiques

High Stability: Strong structural rigidity ensures stable and safe lifting operations.

Efficient Control: The system responds quickly, operates smoothly, and provides precise and efficient operation.

Strong Lifting Capacity: Suitable for lifting heavy objects such as ship components and wind power equipment.

Large Span Design: Can cover multiple tracks or large work areas, adapting to complex working conditions.

Applications

Railway Freight Yards: Loading and unloading railway wagons, improving cargo transfer efficiency.

Outdoor Freight Yards: Used for lifting and stacking bulk goods such as steel and timber.

Subway Construction: Lifting pipes, prefabricated components, and other materials to ensure construction progress.

Factory Production: Material handling and equipment loading and unloading within workshops.

10-ton-U-type-double-girder-gantry-crane

10-ton-A-frame-gantry-crane

10-ton-MG-double-girder-gantry-crane

The truss gantry crane is a rail-mounted lifting device primarily constructed with a truss structure. It typically consists of a main beam, support legs, a lower crossbeam, and lifting, traveling, and electrical control systems. Equipped with a CD1 or MD1 type electric hoist running along the lower flange of the main beam's I-beam, it is suitable for various indoor and outdoor material handling environments. The structure is available in full-truss and semi-truss configurations, featuring lightweight construction, strong wind resistance, and easy installation and maintenance, making it particularly suitable for windy or soft ground conditions.

Caractéristiques

Lightweight structure: The truss design results in a low self-weight and reduced foundation load requirements.

Strong wind resistance: The open structure has low wind resistance, making it suitable for open or windy areas.

Flexible operation: Supports ground control, remote control, and cab operation, adapting to various working conditions.

Applications

Suitable for outdoor freight yards, steel handling, bridge construction, port warehousing, and mining and metallurgy applications. It is especially suitable for environments requiring frequent movement or those with strong winds. It can also be used for workshop material handling, warehouse stacking, dock loading and unloading, construction component installation, and ore lifting operations.

10-ton-MH-single-truss-gantry-crane

10-ton-BMH-semi-gantry-crane

10-ton-BMG-semi-gantry-crane

| Parameter name | Regular range |

| Capacité de levage nominale | 10 tons |

| span | 10-35 meters |

| Hauteur de levage | 6-30 meters |

| Job Level | Level A3- A5 |

| Vitesse de levage | 0.8-8m/min |

| Car running speed | 10-30m/min |

| Cart running speed | 20-45m/min |

| Power supply mode | Three-phase AC, 380 V , 50 Hz |

| Model type | Portée (m) | Hauteur de levage (m) | Usage scenarios | Reference price (USD) |

| Single-girder gantry crane | 8-28 | 6-30 | Freight for small and medium-sized workshops and warehouses | $18,000-25,000 |

| Double-girder gantry crane | 8-31.5 | 6 - 30 | Steel mills, shipyards , chemical plants | $35,000-50,000 |

| Semi-gantry crane | 10-20 | 1 - 3 0 | Warehouse wall area , workshop assembly line | $ 14,000 - 20,000 |

| Truss gantry crane | 12-35 | 6 - 18 | construction sites, ports | $32,000-45,000 |

| Portable gantry crane | 2 - 12 | 1-9 | Temporary repairs, frequent relocation, small workshops | $8,000-15,000 |

| RTG gantry crane | 1 2 -30 | 6-30 | Port container yard and logistics park | $ 36000-57000 |

The above prices are for reference only and may vary depending on custom requirements (e.g., special coatings , additional spreader attachments), quantity, and other factors. Please contact us with your specific requirements for the latest and most affordable quote.

Nucleon Cranes provides customized 10-ton gantry crane solutions, featuring modular design based on specific customer needs. While ensuring structural stability and standardized production, our cranes adapt to various site conditions.

Main customizable parameters include:

Lifting Capacity: 10 tons (customizable)

Span: Customizable

Lifting Height: Customizable

Control Method: Choice of pendant control or remote control

Hoist Type: Equipped with electric wire rope hoist, chain hoist, or explosion-proof hoist

Working Class: A3–A5

Certification Standards: Complies with CE, ISO, EAC, and other certification requirements

For further information or to discuss your specific requirements, please contact our technical team. We will provide a professionally tailored solution and technical support based on your actual working conditions.

Nucleon is a gantry crane manufacturer and supplier with 20 years of production and R&D experience and a team of professional engineers. We offer custom design services for a variety of crane types, including RTG gantry cranes, ponts roulants, and semi-gantry cranes. If you are interested in purchasing a 20-ton gantry crane, please nous contacter for solutions and a quote.

Fournisseur professionnel de grues de levage, spécialisé dans la fabrication de ponts roulants, de grues à portique, de grues à flèche et de palans électriques, etc.

Crane Industry Zone, Changyuan City, Henan Province, China