An EOT crane stands for an electric overhead crane. It relies on a fixed track system mounted on the facility's ceiling or steel beams to perform vertical lifting, horizontal movement, and load positioning. EOT cranes are stationary cranes ideal for performing repetitive, high-volume lifting tasks within a specific work area. Compared to diesel-powered equipment, EOT cranes offer increased efficiency, greater maneuverability, quieter operation, and reduced environmental impact. This article will provide a basic understanding of EOT cranes and provide a better user experience.

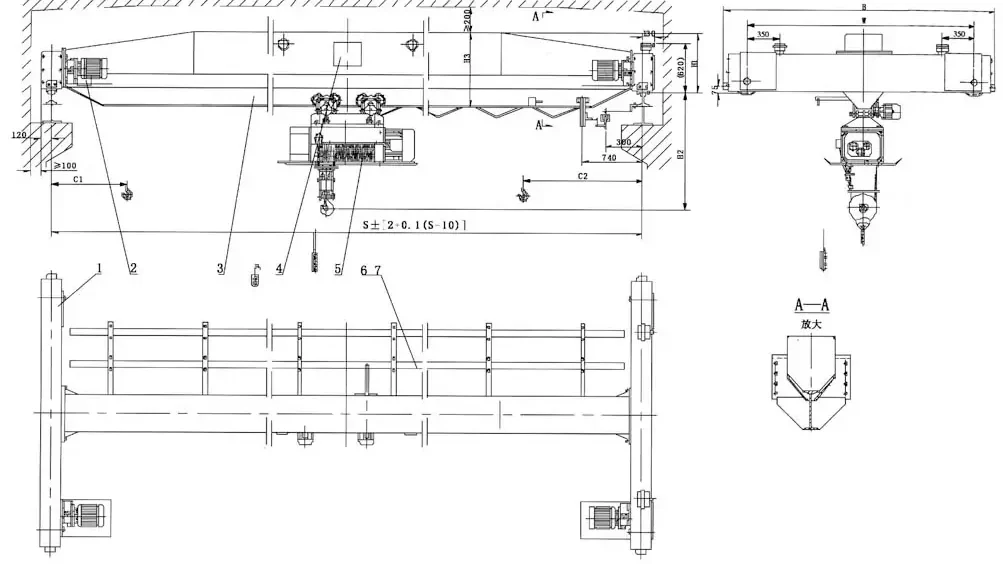

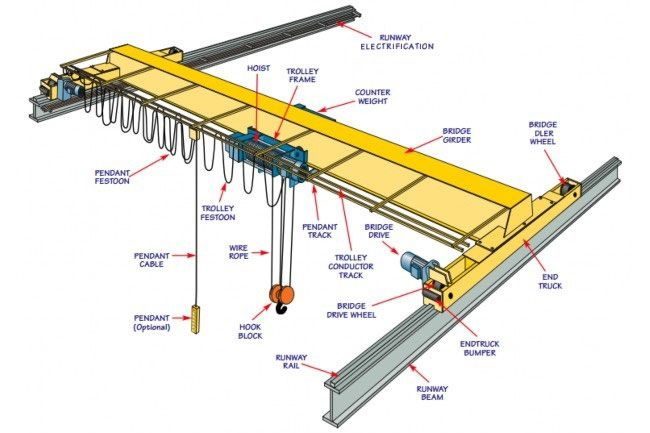

Structural Design

The functionality of an EOT crane comes from its carefully designed structure, with components working together to safely move heavy loads.

Bridge Girder: The main horizontal beam that spans the width of the work area and supports the weight of the load and the crane itself. Some cranes have a single girder for lighter loads, while others have a dual girder for greater load capacities.

End beams: Located at both ends of the bridge main beam, they contain motors and wheels that enable the crane to travel along the elevated track, ensuring smooth movement of the crane along the length of the facility.

Hoist: The lifting core of a crane, consisting of the motor, gearbox, drum, and hook assembly. The hoist operates on a trolley that moves horizontally across the bridge girder, enabling precise positioning of the load.

Control system: Operated via a control box, remote control, or operator's cab, it regulates the crane's operations, including longitudinal movement along the tracks, lateral movement along the bridge, and vertical lifting. Modern EOT cranes are often equipped with variable speed controls for increased operational precision.

Track system: A fixed track installed on a column or building structure that provides guidance for the bridge main beam and determines the reach of the crane.

How EOT Cranes Work

The basic working principle of an EOT crane is the coordinated operation of the electrical drive system, mechanical transmission system, and control system, which together enable the three-dimensional movement of heavy loads.

Electric Drive System

The electric motor serves as the power source, typically a three-phase asynchronous motor.

The motor drives the wire rope drum or wheels through a reduction gearbox, providing the necessary torque for lifting or traveling motions.

Mechanical Transmission System

The motor torque is transmitted through a coupling → reducer → drum → wire rope → hook, allowing the hook to move up and down.

The long travel and cross travel mechanisms are powered by motors that drive the wheels along the crane runway and bridge rails, enabling horizontal movement.

Control System

Composed of the electrical control cabinet, variable frequency drive (VFD), limit switches, and remote controller.

It enables speed control, position limitation, overload protection, and emergency stop functions.

Modern EOT cranes often use VFD control, which ensures smooth starting, precise positioning, and energy-efficient operation.

Safety Protection and Signal Feedback

Overload protectors prevent the crane from operating beyond its rated capacity.

Limit switches prevent the trolley or hook from exceeding safe travel limits.

Sensors and feedback systems monitor the crane’s operational status, supporting automated and safe operation.

In summary:

The EOT crane operates by using an electric motor as the driving source, transmitting mechanical motion through reduction and rope systems, and coordinating these actions through an intelligent control system to safely and efficiently move loads in three dimensions.

After understanding how it works, let's explore the different types together.

Types of EOT Cranes

EOT cranes are classified according to their design, load capacity, and intended use. The following are the most common types:

Single Girder ETO Crane

Design features: It adopts a single-bridge main beam, which is lighter and has a more compact structure.

Scénarios d'application: Suitable for light to medium load tasks with limited space in workshops, warehouses ,and assembly lines. It is cost-effective and easy to install.

Double Girder ETO Crane

Design features: Two parallel bridge beams are used, which provide better stability and higher load-bearing capacity.

Scénarios d'application: Suitable for heavy-duty operations in steel mills, foundries, ports, and construction sites. Capable of handling large and heavy objects, and usually equipped with an auxiliary lifting mechanism for increased flexibility.

Underslung EOT Crane

Design features: The main beam of the bridge is suspended on the track instead of being placed on top of the track, which saves vertical space.

Scénarios d'application: Suitable for low-headroom building facilities and places with limited vertical space.

Spécifications

| Crane type | Carrying capacity range | Span range | Lifting height range | power supply | Typical lifting speed |

| Single Girder EOT Crane | 1–32 tons | 5–28 meters | 3–12 meters | 380V, three-phase | 5–15 m/min |

| Double Girder EOT Crane | 5–800 tons | 10–35 meters | 6–30 meters | 380V, three-phase | 3–20 m/min |

| Underslung EOT Crane | 0.5–20 tons | 5–20 meters | 2–10 meters | 380V, three-phase | 4–12 m/min |

Maintenance

Proper maintenance is essential for the safe and efficient operation of EOT cranes. Promptly correcting faulty components can eliminate most potential hazards, prevent downtime, reduce the risk of accidents, extend equipment life, and ensure stable lifting operations.

Visual Inspection: Check for loose bolts, cracks in the main beam or hook, and signs of wear on the rope or chain to ensure the hook locking mechanism is functioning properly.

Lubrication: Apply lubricant to the trolley wheels, hoist mechanism bearings, and rails to reduce friction and prevent rust.

Electrical System Inspection: Check cables, connectors, and controls for damage or overheating, and test the emergency stop button to ensure proper operation.

Load Testing: Regularly test the crane for the rated load to verify its lifting capacity and safety mechanisms.

Track Alignment: Ensure the tracks are properly aligned to prevent uneven wheel wear and reduce stress on the bridge beams.

EOT crane maintenance is best achieved through regular inspections, such as weekly, monthly, and annual inspections of varying intensity and requirements. Detailed maintenance records should be kept for all maintenance and inspections, and these records should be properly stored to facilitate subsequent and future inspections.

Conclusion

EOT cranes, with their high efficiency, precision, and environmental friendliness, have become indispensable equipment in modern industry. Only with a thorough understanding of EOT cranes can they be used safely and efficiently. If you require crane customization, maintenance, or repair, please contact Nucleon. Our engineers will provide you with professional advice.