In the world of industrial lifting and material handling, electric hoists are indispensable tools that enhance efficiency, safety, and productivity. Whether you're working in construction, manufacturing, or warehousing, electric hoists simplify heavy lifting tasks with precision and ease. This blog will explore what an electric hoist is, its core components, types, working principles, and price ranges, helping you make an informed decision for your lifting needs.

Table of Contents

- What is an Electric Hoist?

- Electric Hoist Parts

- How Does an Electric Hoist Work?

- Common Types of Electric Hoists

- What is the difference between a manual and an electric hoist?

- What is the use of an electric hoist?

- What is the difference between an electric winch and an electric hoist?

- Electric Hoist Price and Factors Affecting the Price

- Electric Hoist Price List

- Conclusion

What is an Electric Hoist?

An electric hoist is a kind of electric lifting equipment for lifting, lowering, and moving heavy objects horizontally or vertically. It is powered by electricity and is widely used in construction, manufacturing, logistics, and warehousing industries. Electric hoists are efficient and reliable, and require very little labor to handle heavy loads.

Electric Hoist Parts

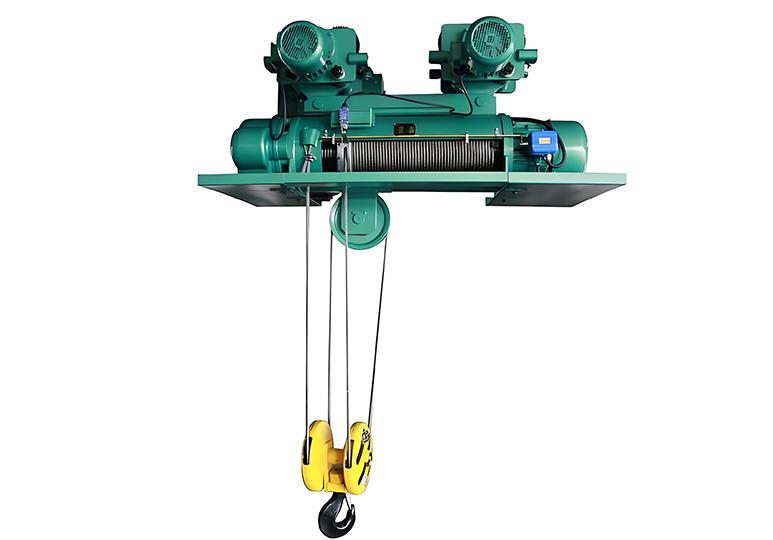

The electric hoist consists of main components, including an electric motor, gearbox, drum or sprocket, wire rope or load chain, hook assembly, braking system, control system, and limit switches. Below is a basic introduction to each component:

- Motor: Provides the power to lift and lower loads.

- Hook: Attaches to the load for secure lifting.

- Chain or Wire Rope: Transmits the lifting force from the motor to the load.

- Control Panel: Allows operators to control the hoist's movements.

- Brake System: Ensures safe stopping and holding of loads.

- Gearbox: Converts the motor's high-speed rotation into high-torque lifting power.

- Drum or Sheave: Guides and stores the chain or wire rope during operation.

How Does an Electric Hoist Work?

An electric hoist is an efficient lifting device that uses an electric motor to drive a hoisting mechanism for moving heavy loads. Its basic operating principle is as follows: After the motor starts, power is transmitted through a gear reduction unit to the drum or sprocket, thereby driving the wire rope or chain to lift or lower the load, enabling vertical movement of heavy objects. Additionally, electric hoists are typically equipped with a braking system and limit switches, ensuring safe and reliable operation.

For a more intuitive understanding of the electric hoist's operation, please view the video demonstration below.

Common Types of Electric Hoists

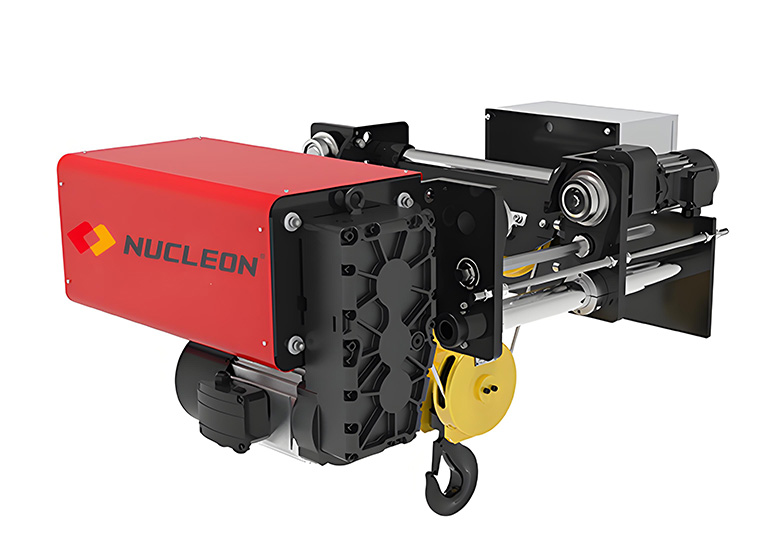

European Electric Hoist

Lightweight design, compact structure, lower clearance height, and higher safety level.

Explosion-Proof Electric Hoist

Designed for hazardous environments, such as chemical plants or oil refineries.

What is the difference between a manual and an electric hoist?

- Manual Hoist: Requires physical effort to operate, suitable for light loads and occasional use.

- Electric Hoist: Powered by electricity, capable of handling heavier loads with minimal effort, ideal for frequent or industrial use.

What is the use of an electric hoist?

Electric hoists are usually used in conjunction with cranes, gantries, jib cranes, rail systems, and other equipment to meet the lifting needs in different scenarios. Widely used in the following fields:

- Manufacturing industry: for material handling and equipment installation on production lines.

- Construction industry: for lifting building materials or equipment.

- Logistics and warehousing: for loading, unloading, and stacking of goods.

- Automobile maintenance: for lifting engines or other heavy parts.

- Mining and ports: for heavy equipment handling and installation.

What is the difference between an electric winch and an electric hoist?

Electric winches and electric hoists, though both used for moving and lifting heavy objects, exhibit distinct differences in structure, operating principles, and application scenarios.

- Electric hoists are primarily designed for vertical lifting of loads. Typically equipped with wire rope or chain, they use an electric motor and reduction gear to drive a drum or sprocket, enabling smooth vertical movement of the load. They are commonly used in fixed or semi-fixed locations such as workshops, warehouses, and construction sites. Compared to electric winches, they offer greater precision control, higher load capacity, and enhanced operational safety.

- Electric winches, conversely, are primarily employed for towing or pulling objects, frequently used for horizontal or inclined movement. Examples include vehicle recovery, ship towing, or heavy machinery relocation. Winches feature simpler construction, primarily relying on an electric motor to drive a drum to wind cable or rope. While their lifting height and load precision typically fall short of electric hoists, they excel in pulling force output and towing applications.

Ultimately, the choice between an electric hoist and an electric winch should be determined by the direction of operation, load type, and application scenario to achieve optimal efficiency and safety.

Electric Hoist Price and Factors Affecting the Price

The price of an electric hoist depends on several factors such as specifications, features, and intended use. Here is an analysis of the key factors that affect the cost of an electric hoist:

Capacité de levage

The maximum weight that an electric hoist can lift is one of the main factors affecting its price. Hoists with larger capacities need to be manufactured with stronger materials and advanced mechanisms, so they are more expensive. A 0.5-ton electric hoist is much cheaper than a 10-ton electric hoist.

Hoist Type

Different types of electric hoists, such as chain electric hoists, wire rope electric hoists, and explosion-proof electric hoists, have different price ranges depending on their design and features.

- Chain hoist price: Generally, more affordable and suitable for medium-duty tasks.

- Wire rope hoist price: It is more expensive due to its ability to handle heavier loads and longer lifting heights.

- Explosion-proof hoist price: It is the most expensive due to its specialized safety features for hazardous environments.

Lifting height and speed

The maximum lifting height and lifting speed of a hoist affect its price. Hoists with higher lifting heights and variable speeds are more expensive.

Power supply and motor type

The motor type (single-phase or three-phase) and power requirements affect the price. Three-phase motors are typically 20-30% more expensive than single-phase models of the same capacity, but are more efficient and durable.

Additional features

Note: Features such as remote control, overload protection, variable speed, and smart monitoring systems increase the price of electric hoists.

Specific application requirements

Hoists designed for special applications (such as high-temperature environments, corrosive environments, or explosion-proof settings) are more expensive due to additional safety and durability features. For example, an explosion-proof crane used in a chemical plant may cost 2-3 times more than a standard crane.

Electric Hoist Price List

The price of electric hoists typically varies based on factors such as lifting capacity, lifting height, operating mode, and configurations (e.g., explosion-proof, low-headroom, or variable frequency control). Below is a general price range based on different lifting capacities and types for your reference. Please note that actual quotations will be determined according to your specific operating conditions, custom requirements, and project configurations.

| Capacité de levage | Price Range (USD) |

|---|---|

| 0.5 Ton Electric Hoist | 200−500 |

| 1 Ton Electric Hoist | 300−800 |

| 2 Ton Electric Hoist | 500−1,200 |

| 3 Ton Electric Hoist | 800−1,800 |

| 5 Ton Electric Hoist | 1,500−3,000 |

| 10 Ton Electric Hoist | 3,000−6,000 |

For precise electric hoist pricing and technical solutions, feel free to contact our sales engineers at any time. We will provide tailored selection recommendations and quotation proposals.

Conclusion

In summary, the electric hoist is an electrically powered, highly efficient lifting device primarily used for lifting, transporting, and loading/unloading heavy objects. It features a compact structure, convenient operation, simple maintenance, and strong load-bearing capacity. Based on varying operational requirements, it comes in multiple types, including wire rope electric hoists, chain electric hoists, and explosion-proof electric hoists. These are suitable for applications in factory workshops, construction sites, warehousing and logistics, energy, mining, and other sectors.

If you are seeking a reliable, cost-effective electric hoist solution, our engineering team offers professional selection and customization services. Contact us today to receive the optimal electric hoist solution and quotation tailored to your project requirements!