Gantry cranes are essential equipment for lifting and moving heavy objects in modern industry . However, different cranes, due to their varying designs and materials, are suitable for different applications and functions. Single-girder and double-girder gantry cranes are the two most common choices when selecting a model . Their structural design, performance , and application scenarios differ significantly , and choosing the right model can significantly optimize operational efficiency and cost control. This article will examine various factors and practical application scenarios to help readers understand the differences and characteristics between the two types and find the equipment that best meets their project needs.

Structural Differences Of Gantry Cranes

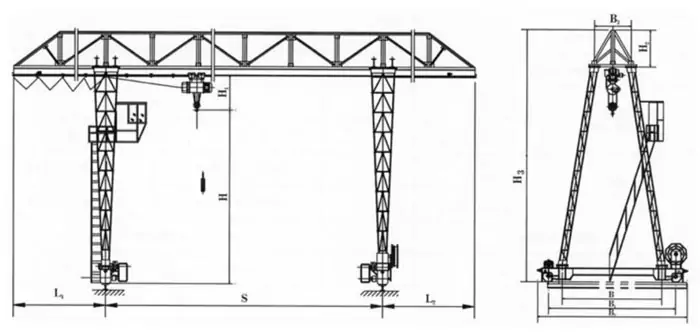

First, structural differences directly determine the performance of the two crane types . Single-girder gantry cranes feature a horizontal main girder at their core, supported by two vertical outriggers with running gear at the base. A hoisting trolley is mounted on the lower flange of the girder, and most electrical equipment is housed in a small compartment within one of the outriggers. This simple overall structure is primarily designed for light- and medium-load operations, emphasizing a balance between cost and space efficiency.

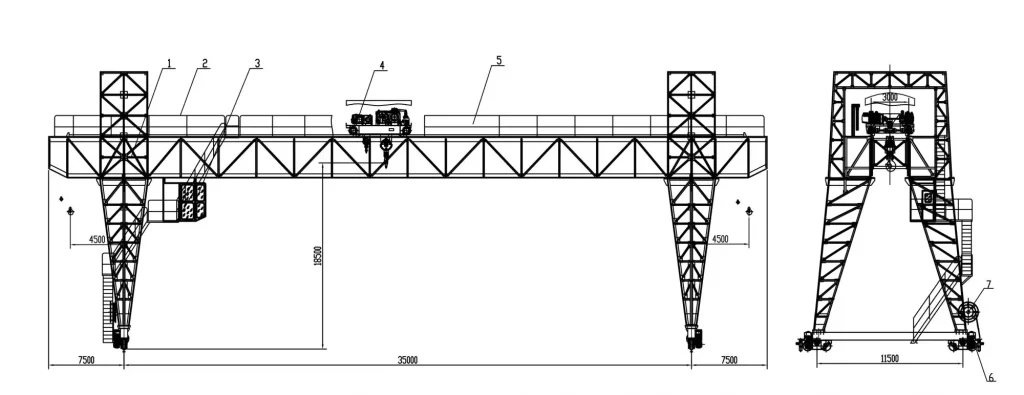

Double-girder gantry cranes utilize two parallel horizontal main beams supported by four outriggers or two reinforced outriggers. A hoist trolley is located between the two beams, and the electrical control system is often housed in a separate operator's cab. Designed for heavy-duty operations, the double-girder structure provides enhanced stability and rigidity, making it suitable for applications requiring high intensity and precision.

Core Advantages

Single girder gantry crane

More controllable costs : The required amount of steel is less, the manufacturing process is relatively simple, and the initial procurement cost is more advantageous than the double main beam. It is especially suitable for small and medium-sized enterprises with limited budgets and can effectively reduce the pressure of initial equipment investment.

Easy installation and maintenance : With fewer parts, the installation process is simpler, which can shorten the equipment production cycle; daily maintenance does not require complicated operations, and only requires focusing on the status of the lifting mechanism and outrigger wheels, which can reduce equipment downtime and maintenance time.

Strong spatial adaptability : It has a lower vertical height requirement and a smaller turning radius . It can also operate flexibly in environments with low ceilings or narrow spaces.

Flexible functional expansion : By adding accessories such as spreaders, suction cups, hooks, etc., it can quickly adapt to the handling needs of different types of goods such as pipes, pallets, small machinery, etc., without the need for major modifications to the main structure.

Double girder gantry crane

Outstanding heavy-load capacity : The double beams bear the load together and evenly distribute the load, which can easily cope with the handling needs of heavy and even ultra-heavy loads. It is an indispensable core equipment in heavy-load industries such as shipbuilding, steel, and port container handling.

High stability and safety : The main beam has strong rigidity, small deformation after being stressed, and low shaking of cargo during operation; at the same time, it is equipped with standard anti-sway system, overload protection, emergency brake and other safety devices, which can greatly reduce operation risks.

Wider operating range : It can cover a wider operating area and has a more advantageous lifting height. It can adapt to scenarios such as large cargo yards and aviation manufacturing that require large-scale and high-altitude operations, reducing blind spots in operations.

Durability and Intelligent Compatibility : Typically constructed from higher- strength steel , these cranes can withstand the wear and tear of long-term, continuous operation, extending their service life . Their overall structure is more stable and adaptable to modern intelligent systems , expanding operational scenarios.

Main disadvantages

Single girder gantry crane

Limited load capacity : Due to the limitation of the single-beam structure, it cannot withstand heavy or ultra-heavy loads and can only meet light and medium load operations. It is difficult to adapt to heavy objects such as steel coils and ship sections.

Low structural strength : Under high load or strong wind conditions, a single main beam is prone to significant deformation .

Insufficient room for upgrades : The structural design is relatively fixed, making it difficult to increase the lifting capacity through subsequent modifications. It is also impossible to integrate complex automation functions such as AI load monitoring and fully automatic positioning, making it difficult to adapt to upgrades in future operational needs.

Double girder gantry crane

High cost threshold : Not only is the purchase price significantly higher than that of a single main beam, but installation also requires a professional on-site team and site pre-treatment, resulting in a high initial investment . Long-term energy consumption and maintenance costs are also higher.

Large space requirements : The wide leg spacing and complex main beam structure require a larger installation site and higher vertical space. It cannot be adapted to compact environments such as small freight yards and low-ceiling factories, and has strict requirements on site conditions.

High maintenance complexity : There are many parts and the structure is sophisticated. Daily maintenance requires checking multiple key parts such as double-beam connections, trolley tracks, and leg reinforcements. The maintenance process is cumbersome and requires higher professionalism from the operation and maintenance team.

Factors To Consider When Choosing A Model

The core of model selection is to accurately match the equipment with actual needs. This requires a comprehensive evaluation of multiple factors. The following four dimensions can serve as key references.

Load type : If the cargo you handle daily is mainly light to medium loads, and there is no need to handle eccentric loads such as steel coils and ship sections, a single main beam will meet the needs. If you need to frequently handle heavy or extremely heavy loads, or often face eccentric loads, a dual main beam is the inevitable choice.

Site Environment : If the work site is cramped, ceiling height is limited, or the work is done on a temporary construction site , a single main beam is more suitable because it is lighter, has lower ground load requirements, and does not require additional foundation reinforcement . If the work area is in a large area such as a port , has ample vertical space, or the ground has been reinforced to withstand the pressure of equipment operation, a dual main beam is more suitable.

Operation frequency and intensity: A single main girder is suitable for low-frequency or medium-intensity operations , such as daily cargo loading and unloading in warehouses, but cannot withstand long-term continuous operation . A dual-girder structure, on the other hand, offers greater structural durability and can handle long-term continuous operation, making it suitable for high-intensity production scenarios such as ports and manufacturing plants.

Budget and long-term planning: If your budget is limited and you don't plan to expand your operations in the future, a single main girder system offers better value for money . If you're looking for long-term equipment durability or have plans to upgrade your automation system in the future, the higher investment in a dual main girder system will offer greater long-term value.

Practical industry applications

Combining the operating scenarios of specific industries can more intuitively judge the adaptability of the two models. The following common application scenarios can provide reference.

used in small warehouses with low ceilings to transport pallets, cartons, or small machinery . They are also frequently used on local construction sites to move concrete blocks, rebar, and construction tools within confined spaces . In the light manufacturing sector, they are used for intermittent operations to transport light to medium loads, such as automotive parts and electronic components.

Double-girder applications focus more on heavy-duty operations . Port terminals use them to load and unload containers over wide areas . Shipyards rely on them for high-precision lifting of ship sections or heavy engines . Steel mills use them to transport heavy cargo such as steel coils and steel components in high-temperature, continuous operation environments.

Conclusion

The choice between a single-girder and a double-girder gantry crane is essentially a matter of finding a balance between demand, cost, and efficiency . If you still have questions after reading the above, contact Nucleon for a customized evaluation. Our professional team of engineers and actuaries can provide precise selection recommendations and help you tailor a cost-effective solution . Choosing the right equipment not only improves operational efficiency and ensures production safety, but also provides strong support for long-term operations .