What is an EOT crane?

The EOT crane (Electric Overhead Travelling Crane) is one of the most widely used bridge cranes in modern industry. It functions as an overhead travelling crane, efficiently, safely, and precisely lifting and moving heavy materials indoors along fixed overhead rails. It rapidly resolves goods handling challenges. Different EOT crane types serve distinct purposes, addressing challenges in varied scenarios. Below, we explore the 5 most common types of EOT cranes, along with their features, applications, and benefits.

5 Main Types of EOT Cranes

- Single-girder EOT crane

- Double-girder EOT crane

- Underslung EOT crane

- Explosion-proof EOT crane

- Grab bucket EOT crane

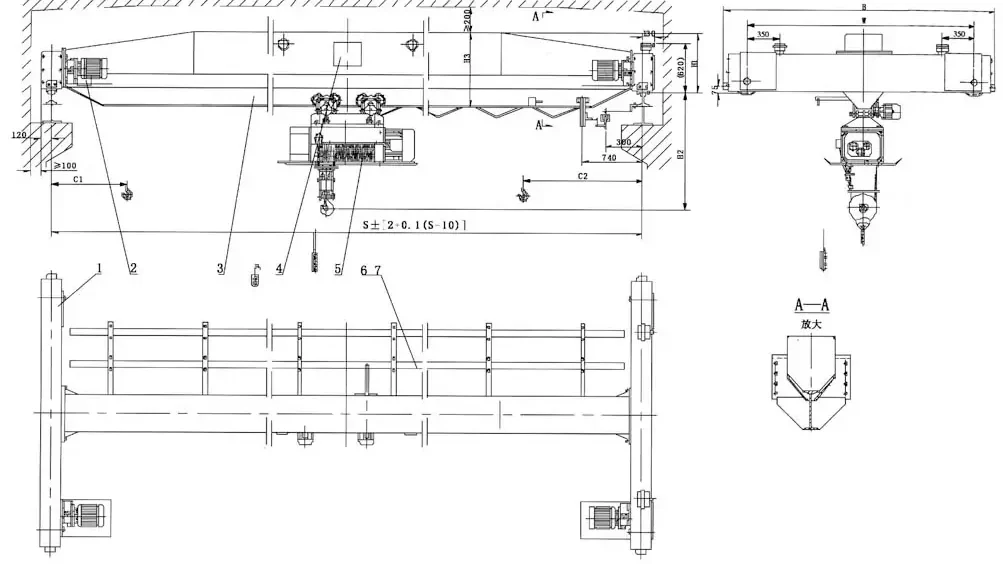

Single-girder EOT crane

Características

The single-girder EOT crane consists of a horizontal beam supporting the hoist, which is supported by two end beams, each of which is equipped with a pair of wheels driven by an electric motor and gearbox unit. The wire rope hoist is suspended below the horizontal beam and can be operated from an operating station suspended from the hoist or a radio remote control.

Ventajas

Cost-effective: Single-girder cranes are generally more economical than double-girder cranes. They are simpler in design and less expensive to manufacture and install.

High space efficiency: The design is relatively compact, suitable for use in areas with tight span space, and is also easy to install.

For light to medium duty applications: Primarily designed for loads up to 20 tonnes and spans up to 25 metres, it is ideal for light and medium duty workshop work.

Aplicaciones

Single-girder EOT cranes are used across a wide range of industries. They are often employed in small production facilities, warehouses, and workshops for general material handling tasks. For example, in furniture manufacturing plants, they are used to lift and move wooden panels, furniture components, and finished products. In some specialized cases, they can also be used to handle hot metal ladles.

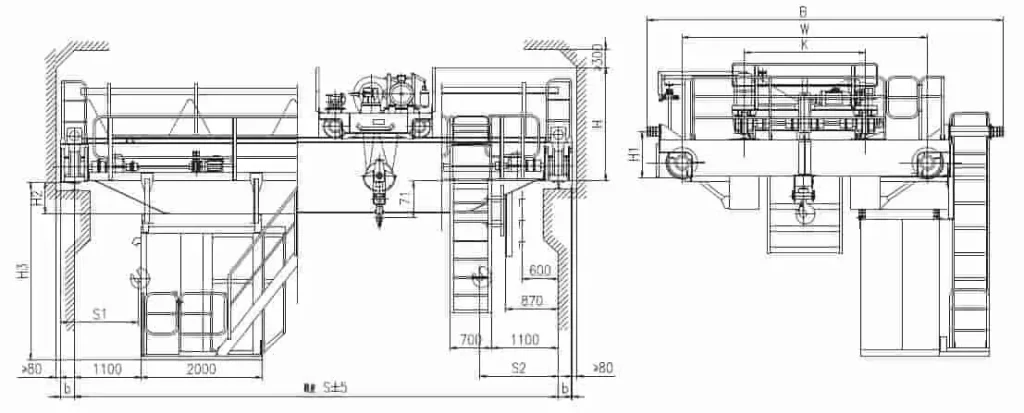

Double-girder EOT crane

Características

Double-girder EOT cranes have two horizontal main beams, providing greater strength and stability, allowing them to handle heavier loads. Their vertical hoisting system typically consists of a bucket winch. The gearbox of this type of crane is typically bottom-mounted, often with a horizontal center splitter for easier maintenance. The crane's brakes utilize bottom-mounted hydraulic thrusters.

Ventajas

High load capacity: Designed for handling heavy objects, the lifting capacity range is typically 5 to 800 tons, suitable for industries that require lifting and moving large and heavy objects.

Durability: High-quality materials and precision-made components provide a rugged construction for long-lasting, reliable operation.

Versatility: Customizable in lifting capacity, speed, and control options. The trolley features ample space for easy maintenance and long-travel wheels with L-shaped housings for enhanced performance.

Aplicaciones

These cranes are used in a variety of heavy-duty industries. In the steel industry, they are used to lift and transport large steel coils, billets, and beams. They are also common in power plants, shipyards, and rolling mills. In shipyards, for example, they are used to lift and position large ship components during construction.

Underslung EOT crane

Características

Suspension EOT cranes feature a unique design where the end beams or end frames travel on the lower flange of the track beams. Unlike top-mounted overhead cranes, the main bridge beams run beneath the crane tracks. Available in single- or double-girder models, single-girder suspension cranes are typically equipped with an electric hoist and are designed for lightweight material handling. Double-girder suspension cranes are hybrid solutions, combining the advantages of an underslung design with the load-bearing capacity of a double girder.

Ventajas

Ahorro de espacio: Usually supported and installed on the ceiling structure or roof structure, it is suitable for workshops or warehouses with low clearance, without the need for additional supporting columns, saving ground space.

Cost-effective: Lightweight design and the use of existing ceiling trusses or roof structures reduce equipment costs. Multiple suspension bridge cranes can be installed side by side and operate simultaneously, increasing production efficiency.

Flexibility: Available in a range of capacities, single-girder models are typically less than 10 tonnes and can be further customised to suit specific application requirements.

Aplicaciones

Suspension EOT cranes are commonly used on assembly lines, in manufacturing plants, repair shops, and production facilities. For example, in automobile assembly plants, they can be used to lift and position auto parts during the assembly process. They are also useful in smaller workshops or areas with limited space, such as machine repair shops.

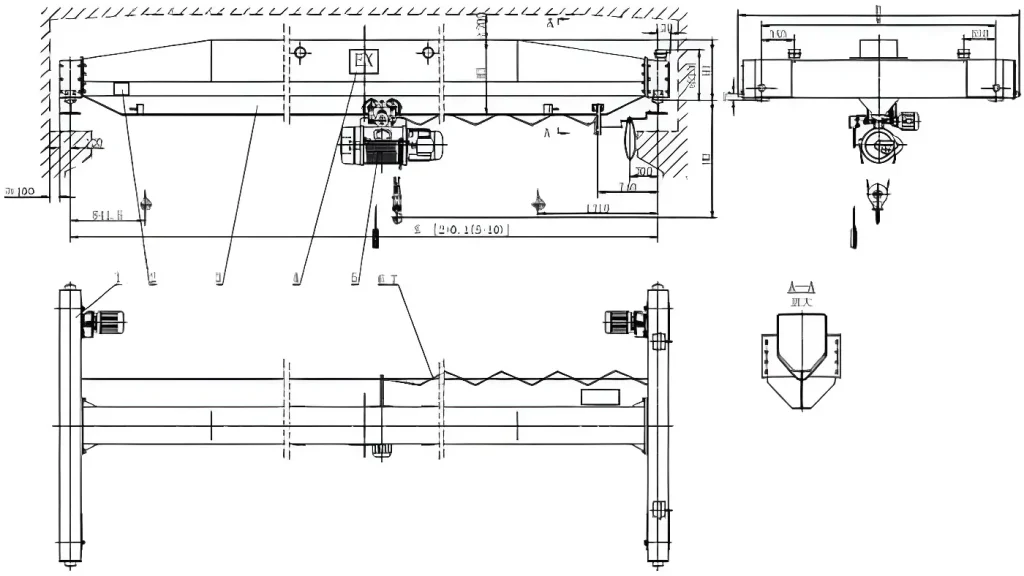

Explosion-proof EOT crane

Características

Explosion-proof EOT cranes are designed for operation in flammable and explosive environments. Their electrical systems utilize an explosion-proof design, and all electrical components undergo special treatment to provide flameproof and increased safety features, effectively preventing explosions caused by sparks and arcs. The mechanical components are also treated with anti-static and anti-spark treatments, resulting in relatively slow operating speeds and smooth starting and braking, minimizing sparks from impact and friction.

Ventajas

Alta seguridad: This is its most core advantage. It can operate safely in dangerous environments with flammable and explosive gases, dust, etc., greatly reducing the risk of explosion and fire.

Strong adaptability: It can adapt to different explosion-proof level requirements and can be customized according to different hazardous environment levels to meet the use needs of various flammable and explosive places.

Good reliability: Using high-quality explosion-proof components and rigorous manufacturing technology, it can work stably and reliably in harsh and dangerous environments, thereby reducing downtime.

Aplicaciones

Explosion-proof electric overhead cranes are primarily used in industries with flammable and explosive hazards, such as petroleum, chemical, pharmaceutical, textile, and coal mining. In petrochemical plants, they can lift and transport flammable and explosive materials such as gasoline, diesel, and chemical raw materials. In coal mining enterprises, they can transport coal and related equipment in flammable and explosive environments, both underground and above ground.

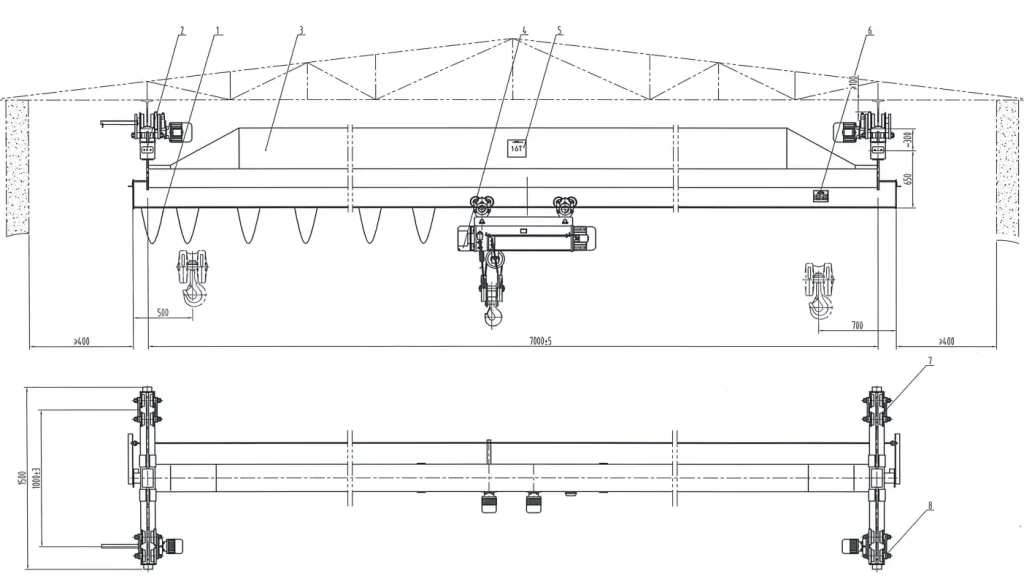

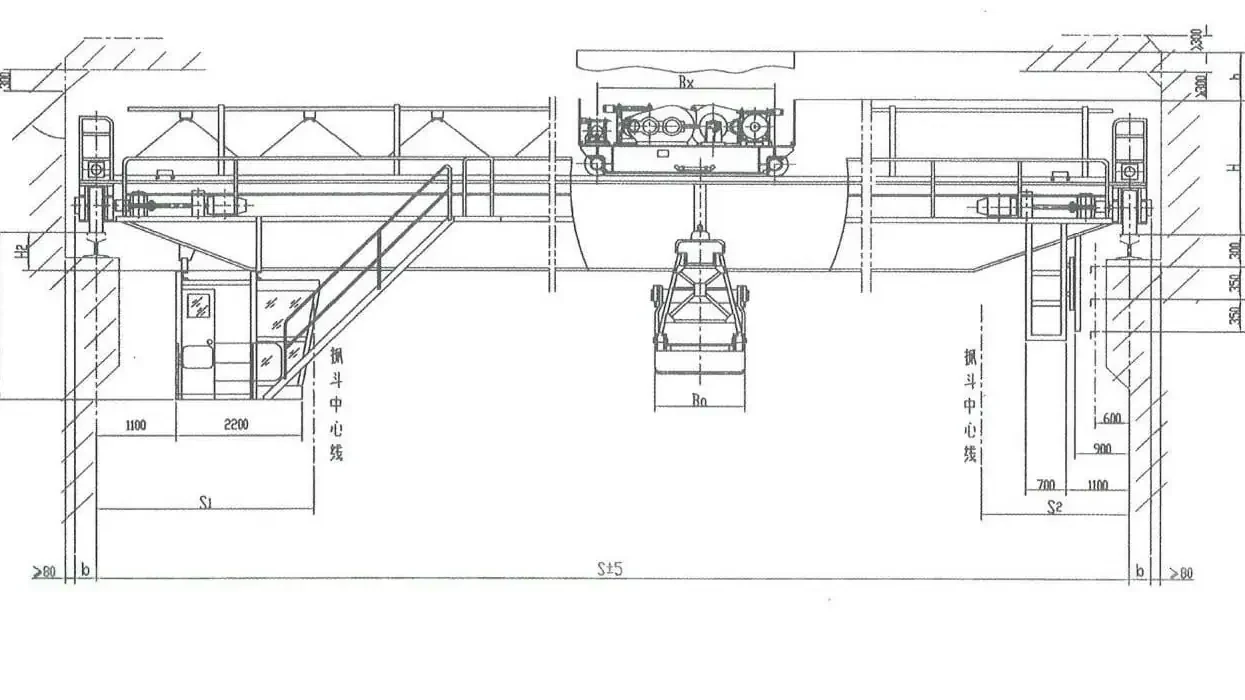

Grab bucket EOT crane

Características

Grab-type EOT cranes are equipped with a grab bucket as a lifting mechanism. The grab bucket typically consists of two or more jaws that open and close via hydraulic or mechanical transmission to grasp bulk materials. The operating mechanism and hoisting mechanism are similar to those of other EOT cranes, but the hoisting mechanism must coordinate with the opening and closing of the grab bucket. A variety of grab bucket types are available, and selection can be tailored to the material's characteristics.

Ventajas

High operating efficiency: It can quickly grab and unload bulk materials, which greatly improves material handling efficiency compared to manual or other non-dedicated equipment. It is especially suitable for the continuous operation of large amounts of bulk materials.

Reduce labor intensity: No manual assistance is required to grab materials, which reduces manual participation, reduces workers' labor intensity, and avoids the risk of manual operation in harsh environments.

Strong versatility: By replacing different types of grab buckets, it can handle a variety of different bulk materials and has strong versatility.

Application Scenario

Grab-type EOT cranes are widely used in ports, stations, mines, power plants, waste treatment plants, and other places. In ports and stations, they are used to load and unload bulk cargo such as coal, ore, and grain from ships and trains; in mines, they are used to transport mined ore; in power plants, they are used to transport fuel coal; and in waste treatment plants, they are used to grab and move garbage and other materials.

EOT Crane Type Comparison Table

| Crane type | Span range | Lifting speed range | Carrying capacity range | Job Level |

| Single-girder EOT crane | 10-20 meters | 8-12m/min | 1-15 tons | A3-A5 |

| Double-girder EOT crane | 15-30 meters | 5-15 m/min | 5-30 tons | A4-A6 |

| Suspension EOT crane | 5-15 meters | 5-10m/min | 0.5-15 tons | A3- A4 |

| Explosion-proof EOT crane | 10-25 meters | 3-6m/min | 2-20 tons | A4-A6 |

| Grab type EOT crane | 15-30 meters | 5-12m/min | 5-30 tons | A5 |

How to Choose the Right EOT Crane

When selecting an EOT crane, consider the following factors:

Load Capacity & Span – Match your operational needs.

Work Environment – Choose explosion-proof types if needed.

Space Availability – For low headroom, choose underslung models.

Frequency of Use – Heavier-duty cycles need double-girder cranes.

Tip: A properly selected EOT crane can increase your operational efficiency by over 25% and significantly reduce maintenance downtime.

Conclusión

Choosing the correct EOT crane type can make a huge difference in your production efficiency and long-term operating costs.

Whether you need a single girder crane for light-duty lifting or a double girder model for heavy industrial applications, our engineering team can design and supply the perfect solution for your facility.

Contact us today to get professional guidance, detailed specifications, and a customized quotation for your EOT crane project.