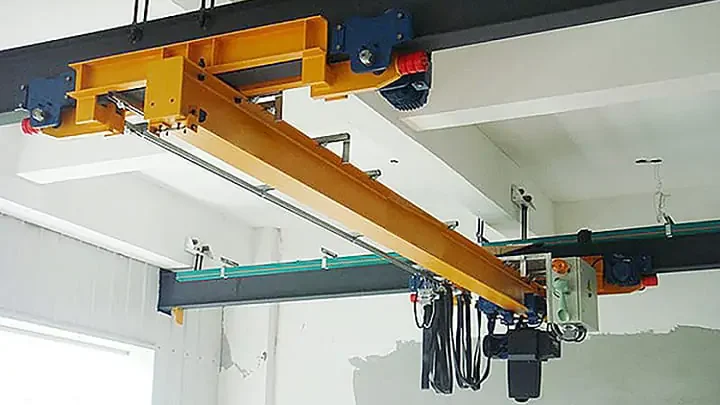

The Underslung EOT Crane, also known as an underhung bridge crane, is a specialized lifting device meticulously engineered for spaces with height constraints. Unlike traditional cranes that rely on ground - supported columns, it suspends from roof trusses or ceiling structures. This unique design makes it a perfect fit for low - headroom buildings, enabling efficient material handling, assembly, and maintenance tasks across various industrial settings.

The Underslung EOT Crane, also known as an underhung bridge crane, is a specialized lifting device meticulously engineered for spaces with height constraints. Unlike traditional cranes that rely on ground - supported columns, it suspends from roof trusses or ceiling structures. This unique design makes it a perfect fit for low - headroom buildings, enabling efficient material handling, assembly, and maintenance tasks across various industrial settings.

Column-less Design: The main beam is suspended directly from the roof structure, eliminating the need for ground support columns. This makes it particularly suitable for workshops and warehouses with complex layouts or limited space.

Low Headroom Compatibility: The compact design maximizes hook height utilization, allowing installation in low ceilings where traditional cranes are impassable.

Compatible with Various Building Structures: It can be directly fixed to reinforced concrete roofs, steel trusses, or mounted via a suspension rod, adapting to complex building forms such as flat and pitched roofs.

Modular Design: Standardized components facilitate installation and allow for rapid expansion and disassembly, making it suitable for both existing factory renovations and new construction projects.

Efficient Operation and Safety: The crane supports multiple control methods: wireless remote control and push-button operation. It has adjustable lifting and operating speeds. This enables precise control and better handling efficiency. Standard features include overload protection, limit switches, and an emergency stop. An optional anti-collision system is available. These ensure comprehensive operational safety.

Durability and Low Maintenance Costs: High strength and rigidity come from welded box beams or rolled I-beams. The closed track design reduces dust buildup and component wear. Key components use high-quality materials, with working grades A3-A4. This ensures durability and keeps maintenance costs low.

This type of crane offers a lightweight structure and relatively low cost, with a load range of 0.5 to 10 tons. It is ideal for light loads and low-frequency operations, making it an ideal choice for small workshops, warehouses, pumping stations, and other locations.

This type of crane features a double-girder design, boasting a higher load capacity of 25 tons and a greater hook height. It is designed for medium to high load requirements, particularly when increased hook height is required to lift larger or bulkier loads.

This crane features an explosion-proof design, ensuring safe operation in flammable and explosive environments. It is widely used in hazardous industries such as the chemical, oil, and gas industries, where stringent safety standards and explosion-proof requirements are crucial.

This crane offers a compact structure, elegant appearance, superior performance, and minimal maintenance, designed for high-end manufacturing applications. It is particularly suitable for environments requiring the highest precision and aesthetics.

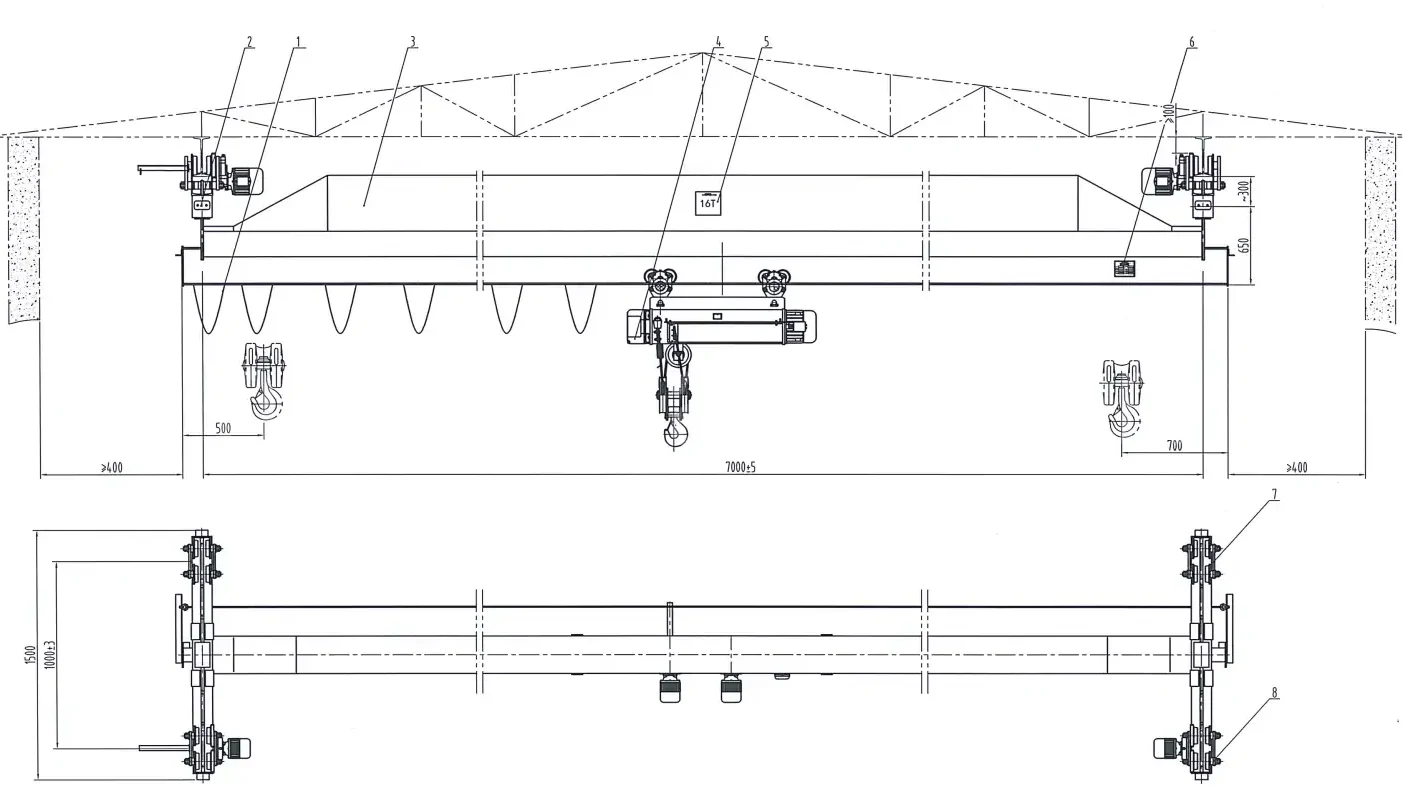

| Parameter | Range |

| Load - Bearing Capacity | 0.5 tons - 25 tons |

| Spannweite | 3 meters - 30 meters |

| Hebehöhe | 6 meters - 30 meters |

| Hebegeschwindigkeit | 5 - 10 m/min |

| Running Speed | 20 - 30 m/min |

| Arbeiterklasse | A3 - A4 |

As a professional underslung EOT crane manufacturer, we offer comprehensive customization services, enabling us to precisely tailor our services to your specific needs. We can customize the core performance parameters of the Underslung EOT Crane, such as load capacity, span, and lifting height, as well as control options such as wireless remote control and manual operation. For specialized environments such as chemical plants and coastal areas, we offer explosion-proof and corrosion-resistant solutions. Furthermore, we offer flexible adjustments to track types and mounting methods to ensure a perfect match for your site conditions.

Underslung EOT cranes are Nucleon Crane's core product. As a leading manufacturer and supplier, we offer a comprehensive product range, including European standard, light, and heavy-duty underslung cranes. With over 20 years of industry experience, we possess deep technical expertise. We offer custom designs tailored to your specific needs. With cranes sold in over 160 countries, we enjoy a strong reputation in the lifting equipment industry. We specialize in efficient, low-maintenance, and reliable systems. These systems optimize the handling of a wide variety of materials within confined spaces, such as small workshops, laboratories, and compact factories, and improve operational efficiency in locations with limited height and floor space. If you require a custom underslung EOT crane, contact us today for a tailored solution and an accurate quote.

Measure vertical sag at the bridge girder's midspan using a laser distance meter or dial gauge. First record the unloaded position, then lift the rated load and re-measure. The difference is the deflection.

Top running cranes are best suited for heavy-duty applications that require high lifting capacity and long travel distances. They are also versatile and customizable, making them ideal for complex lifting tasks.Underslung EOT cranes, on the other hand, are more suitable for lighter loads and low-headroom applications. They are also cost-effective and easy to install, making them an excellent choice for smaller workspaces with a limited budget.

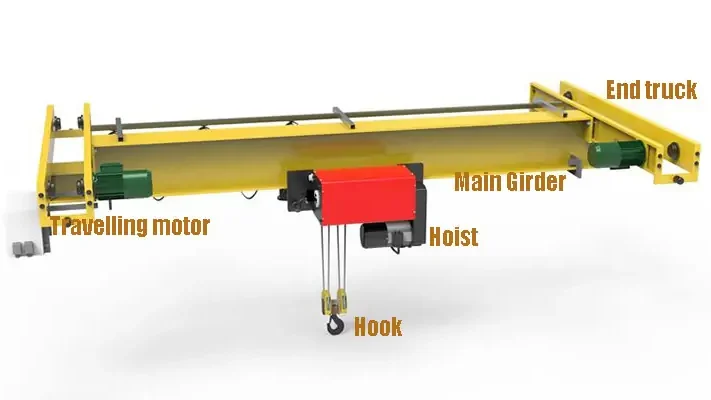

A underslung EOT crane typically includes essential components like the trolley, an electric hoist for lifting, and suspension clamps or frames to securely mount it to overhead structures. Operators control the crane via a wired pendant station or optional radio remote, while safety features include load hooks, limit switches to prevent overtravel, and bumpers. Additional accessories like anti-sway systems, integrated weighing scales, or spreader beams can be added to enhance precision and handle specialized loads, all designed to maximize the crane’s adaptability in space-constrained environments.

Professioneller Anbieter von Hebekränen, spezialisiert auf die Herstellung von Brückenkränen, Portalkränen, Auslegerkränen und elektrischen Hebezeugen usw.

Kranindustriezone, Stadt Changyuan, Provinz Henan, China