The self-propelled scissor lift high-altitude work platform is primarily used to lift workers to elevated positions for maintenance, inspection, cleaning, or installation tasks.

The Self-Propelled Scissor Lift Platform is a versatile lifting device that combines self-propelled mobility with lifting functionality. It is primarily designed for high-altitude work and is suitable for indoor environments such as factories, warehouses, and areas with narrow passageways. Equipped with an advanced electric drive system, it offers features such as maneuverability, ease of operation, low noise levels, and zero emissions.

The Self-Propelled Scissor Lift is fitted with an intelligent control system, making operation simple and intuitive—a single operator can easily perform lifting and movement tasks. Its compact structural design combined with flexible steering performance, allows it to maneuver freely in confined spaces, significantly enhancing high-altitude work efficiency. The platform offers stable load-bearing capacity and reliable safety barriers, making it an ideal alternative to traditional scaffolding.

Self Propelled Scissor Lift

Self Propelled Scissor Lift

The self-propelled electric scissor lift high-altitude work platform is primarily used to lift workers to elevated positions for maintenance, inspection, cleaning, or installation tasks. It enables automatic operation, allowing a single operator to maneuver the platform forward, backward, and turn.

We offer a variety of specifications and models to choose from, and can provide customized solutions tailored to customer needs, including different lifting heights and load-bearing capacities. Please feel free to contact us for detailed technical specifications and customized services!

The Self-Propelled Scissor Lift Platform primarily consists of a chassis system, scissor boom, hydraulic system, electrical control system, work platform, and safety devices.

Chassis System — Equipped with a high-load-bearing steel frame and drive wheel assembly, the equipment moves stably and positions accurately.

Scissor Boom — Constructed with a high-strength steel cross-jointed structure, it ensures smooth lifting and lowering while balancing working height and folded dimensions.

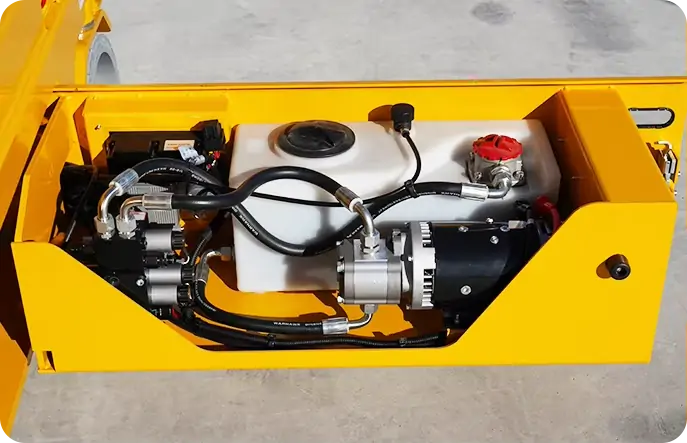

Hydraulic System — Driven by hydraulic cylinders, the scissor arms extend and retract smoothly, providing powerful performance with operational noise levels below 65 decibels.

Electrical Control System — Integrated with an intelligent control panel and sensors, it supports precise operation via wireless remote control or handheld controller.

Work Platform — Features anti-slip steel plate guardrails, with a standard load capacity of 300–500 kg, and optional accessories available to meet special operational requirements.

Safety devices — Includes tilt alarms, emergency descent, collision prevention, and other multiple safety protections, compliant with ANSI/SAIA international safety standards.

Intelligent Maneuverability: Equipped with a fully electric drive system and intelligent steering mechanism, it achieves precise positioning with a zero turning radius, supporting autonomous movement and multi-angle adjustments in confined spaces, ensuring strong operational maneuverability.

All-Condition Adaptability: Featuring an IP54 protection rating design and adaptive tire configuration, it seamlessly handles complex indoor and outdoor environments such as construction sites, warehouses, and industrial facilities, operating stably in temperatures ranging from -20°C to 50°C.

Multi-layered safety protection system: Integrated with 12 safety modules including 3D tilt protection (±3° automatic locking), dual-circuit hydraulic safety valves, and explosion-proof mechanical locking devices, it meets the highest safety certification standards of EN280 Class 3.

Precision hydraulic control technology: Utilizing a load-sensing proportional hydraulic system, it ensures precise positioning and infinitely adjustable lifting speed (6-12 m/min), guaranteeing smooth operation at high altitudes.

Self-propelled scissor lift platforms are suitable for a variety of high-altitude working sites due to their flexibility and efficiency.

| Maximum working height | M | 8 | 10 | 12 | 13.8 | 15.7 |

| Maximum platform height | M | 6 | 8 | 10 | 11.8 | 13.7 |

| Extended table size | M | 0.9 | ||||

| Safe working load | KG | 500 | 450 | 320 | 320 | 227 |

| Extended platform safe working load | KG | 113 | ||||

| Working platform size | M | 2.27×1.12×1.13 | 2.64×1.12×1.13 | |||

| Overall machine dimensions | M | 2.43×1.22×2.28 | 2.43×1.22×2.42 | 2.43×1.22× 2.54 | 2.43×1.22×2.67 | 2.8×1.39×2.66 |

| Overall machine dimensions (guardrail folded) | M | 2.43×1.22×1.71 | 2.43×1.22×1.84 | 2.43 ×1.22 × 1.96 | 2.43×1.22×2.09 | 2.8×1.39×2.09 |

| Wheelbase | M | 1.89 | 2.26 | |||

| Hydraulic oil tank capacity | L | 20 | 20 | 20 | 20 | 25 |

| Gradability | 25% | |||||

| Center ground clearance | M | 0.1/0.02m | ||||

| Turning radius (inner wheel/outer wheel) | M | 0.4/2.4 | 0.45/2.9 | |||

| Maximum number of passengers | 3 | 3 | 2 | 2 | 2 | |

| Lifting speed | m/min | 6-9m/min | ||||

| Machine travel speed (folded state) | km/h | 3.5km/h | 2.7km/h | |||

| Machine travel speed (lifted state) | km/h | 0.8km/h | ||||

| Battery | 4*6V/200ah | |||||

| Tyre size | mm | Φ381×127mm | ||||

| Weight (kg) | KG | 2100kg | 2290kg | 2540kg | 2680kg | 3210KG |

Nucleon was founded in 2005 and is a manufacturing enterprise integrating design, research, invention, and sales, with a strong technical team and R&D production capabilities. We specialize in the manufacture and sale of scissor lifts, cranes, electric hoists, and other equipment, and can provide customized design solutions according to your needs. We offer free technical consultation, a one-year warranty, and lifetime after-sales service. Please contact us for solutions and quotes.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China