Overhead cranes play a key role in material handling, as they lift and transport heavy loads with precision and efficiency across various industries. In fact, many types of bridge cranes exist, each designed to meet specific operational needs. This article will explore their characteristics, advantages, and application scenarios in detail.

Oem Types Of Overhead Cranes

There are many types of bridge cranes, which can be divided into different types according to their lifting capacity, structural form and application occasions. The details are as follows:

1.Divided by Lifting Capacity

1-20 tons light duty overhead travelling crane

Light-duty overhead cranes are suitable for small manufacturing workshops, warehouses, and similar environments, with a lifting capacity ranging from 1 to 20 tons. Their compact and flexible structure enables efficient handling of medium and small-sized material transportation tasks, making them an ideal choice for light industrial settings.

20-800 tons heavy duty overhead travelling crane

Heavy-duty cranes support demanding sectors like steel mills, foundries, and shipyards by lifting loads over 20 tons. Their strong builds and powerful systems move extremely heavy loads safely and steadily, even in tough operating conditions.

2.Divided by Structural Design

Single Girder Overhead Crane

Single-girder overhead cranes use a single bridge supported by end carriages. They lift loads from 1 to 32 tons. These cranes offer high efficiency and cost-effectiveness. Industries like manufacturing, logistics, and automotive widely use them. They suit applications with limited budgets and moderate workloads especially well.

Eigenschaften: light structure, convenient installation and maintenance, etc.

Applicable: used in factories, warehouses, material yards and other different occasions to lift goods, prohibited in flammable, explosive, corrosive media environment.

Double Girder Overhead Crane

Double-girder overhead cranes use a double bridge structure for greater stability. They handle loads from 5 to 800 tons and support large-span operations. These cranes serve industries like construction, mining, and heavy manufacturing. They perform complex and high-intensity lifting tasks efficiently.

Eigenschaften: double girder overhead crane can be equipped with motor grab, electromagnetic chuck and other fetching devices, to meet the needs of lifting various types of materials.

Applicable: factory, warehouse and goods yard for loading, unloading and lifting work, prohibited in flammable, explosive and corrosive gas filled environment work.

3.Divided by Application

Grab Overhead Cranes

Grab overhead cranes feature a grab bucket to handle bulk materials like sand, gravel, or waste. These cranes serve industries such as mining, construction, and waste management by providing efficient loading and unloading solutions.

Eigenschaften

•Efficient loading and unloading: Quickly transport large quantities of bulk materials, such as coal, ore, etc., significantly improving work efficiency.

•Strong adaptability: Suitable for work indoors and outdoors and in harsh environments, including humid and sandy places.

•Flexible and versatile: Different types of grab buckets can be replaced to adapt to various materials, increasing operating flexibility.

Electromagnetic Overhead Cranes

Electromagnetic overhead cranes use electromagnetic force to move ferrous materials. They serve scrap yards, recycling centers, and the steel industry. Their magnetic design enables quick sorting and movement of metal materials, improving operational efficiency.

Eigenschaften

•Non-contact handling: Absorb metal materials without the need for physical gripping devices, suitable for handling magnetic materials such as steel plates and billets.

•Efficient Performance: Simplify the loading and unloading process, and improve work efficiency, especially in steel mills and scrap recycling yards.

•Accurate positioning: Accurately control the strength of the electromagnetic force, stable adsorption and accurate placement of goods.

Explosion-Proof Overhead Cranes

Explosion-proof overhead cranes operate safely in flammable and explosive environments. Specifically, they incorporate explosion-proof components and safety devices to ensure reliable performance. As a result, these cranes are widely used in high-risk industries such as chemicals and petroleum.

Eigenschaften

•Explosion-proof design: All key components (motors, lifting mechanisms, and Electrical components) are made of explosion-proof materials.

•High adaptability: Can be matched with magnets, hook, or C-hook to meet the needs of different working scenarios.

•Safe and reliable structure: Main and end beams are welded with high-quality steel. Non-metallic components are made of anti-static materials.

Insulated Overhead Cranes

The QY insulated bridge crane operates safely in industrial environments with electrical hazards. Specifically, it handles conductive materials in industries such as non-ferrous metal electrolysis and chemical processing..

Eigenschaften

•Multiple safety safeguards: Equipped with dual braking, overload protection, and insulation failure alarm systems to comprehensively mitigate operational risks.

•Precise control performance: Variable frequency stepless speed regulation combined with centralized control in the cab ensures precise and efficient operation.

•Durable structural design: Corrosion-resistant coating and IP54 protection rating extend service life in harsh environments.

Metallurgical bridge cranes

Metallurgical overhead cranes operate reliably under harsh conditions, since they withstand high temperatures and resist wear. Furthermore, these cranes efficiently move ladles, ingots, slabs, and heavy scrap across steel mills, foundries, and non-ferrous metal plants.

Vorteile

•Heat-resistant hooks & motors (H-class insulation)

•Dual brake systems & overload protection

•IP55 protection against dust and moisture

•Customizable span/lift height configurations

Forging overhead travelling crane

The YZ casting crane serves as heavy lifting equipment in steel smelting workshops. It lifts, pours, and stirs molten iron, in addition to handling other high-temperature liquid metal operations.

Vorteile

•Multiple safety mechanisms: The forging crane has overload protection, double emergency brakes, crane switch and travel limit switch.

•High load capacity: YZ Foundry Casting crane has high load-bearing capacity and impact resistance.

•Electrical safety: Casting cranes use protective grounding and high-temperature resistant cables. It effectively prevents leakage and short circuit risks.

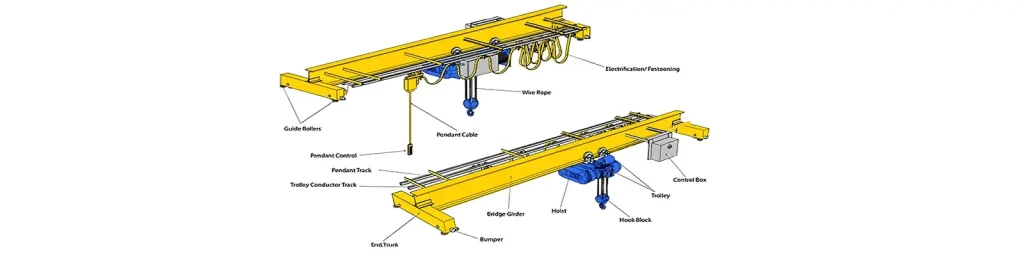

Introduction to Overhead Crane Parts

An overhead crane contains one or two parallel main girders, end girders, a hoisting mechanism, an electrical system, safety devices, and a trolley running mechanism. These main girders join together through cross girders, forming a stable frame structure. The hoisting mechanism attaches to a trolley, which then moves along the upper flange of the main girder and efficiently lifts large-tonnage loads.

Girder

The girder serves as the main load-bearing structure of an overhead crane, spanning the entire facility width. It directly supports both the hoisting device and the trolley, and ultimately determines the crane’s load capacity and operational stability.

Track

Overhead tracks run along both sides of the facility's upper structure, supporting the entire crane system. The crane's girder mechanism travels on these tracks, moving lengthwise to position the crane flexibly across the whole work area.

Lifting device

The hoisting device acts as the core component of an overhead crane, performing all lifting and lowering tasks. It typically consists of a motor, wire ropes, pulleys, and a hook, enabling precise control over both the height and position of the load.

Trolley

The trolley operates as a mobile mechanism on the bridge frame. It carries the hoisting device and moves laterally along the beam, thereby enabling the crane to position loads precisely across the entire bridge coverage area.

End beams

End brackets mount at both ends of the main beam, where they support the full bridge structure and connect to the main beam running mechanism. Moreover, this design allows the crane to move smoothly along the track and reliably bear heavy loads.

Control unit

This system operates the crane through multiple options, including hook control, remote control, or cab operation

Electrical power system

Provides power support for the crane, including motors, cables and power distribution units.

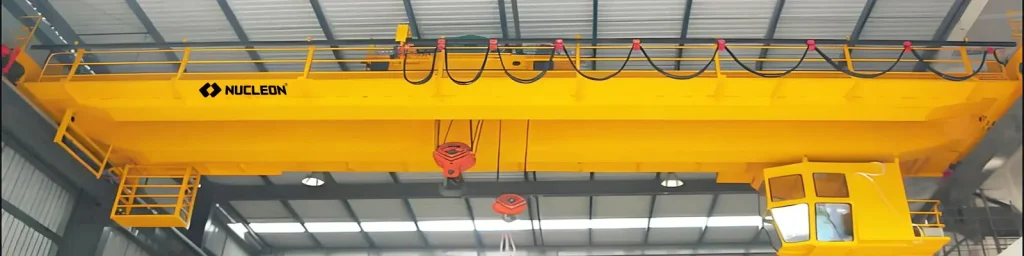

As a well-known manufacturer of overhead cranes in China, Nucleon Crane can provide customized solutions according to your specific needs, including non-standard lifting capacity, lifting height, lifting/running speed, and adjustment of control methods. At the same time, we also provide a full range of services such as design and manufacture of lifting equipment, installation and commissioning, equipment modification, overhaul, maintenance and annual inspection and maintenance.

What is the price of an overhead crane?

In der nachstehenden Tabelle haben wir Preisspannen für Brückenkräne verschiedener Tonnagen angegeben. Diese Preise dienen nur als Referenz. Der genaue Preis des Brückenkrans hängt von Ihren detaillierten Anpassungsanforderungen zum Zeitpunkt des Kaufs ab.

| Tragfähigkeit | Spannweite | Preisspanne |

|---|---|---|

| 10-20 Tonnen | 10-20m | $39,000 - 78,000 |

| 20-50 Tonnen | 10-30m | $78,000 - 198,000 |

| 50-100 Tonnen | 10-30m | $198,000 - 480,000 |

| 100-500 Tonnen | 10-30m | $480,000 - $1,200,000+ |

Summarize

The previous sections detailed the types, components, and pricing of overhead cranes. Various crane types serve different industries and operating environments. Whether in a small, light-duty workshop or a large, heavy-duty industrial site, each crane offers distinct features and benefits. By understanding these characteristics and applications, you can confidently select the most suitable lifting solution.

For customized overhead crane solutions, please feel free to contact us. Our professional team will provide you with personalized advice and help you choose the most suitable equipment.