Project Overview

In August 2025, we received an email inquiry from a steel mill in the Americas regarding a floor mounted slewing jib crane. A mill in Mexico, specializing in iron and steel production, needed a fixed-column cantilever crane for precise material handling in its workshop. The jib crane is easy to install and maintain. Its adaptability and reliability make it essential for optimizing material transfer processes.

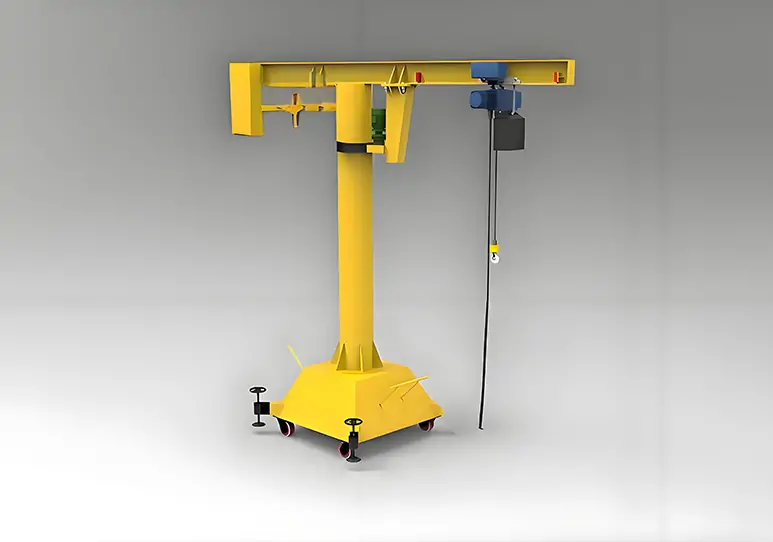

Floor Mounted Slewing jib Crane

Customer Requirements

The American Steel Plant identified the following requirements when selecting a floor mounted slewing jib crane:

- Flexible installation: The fixed column jib crane is not dependent on building structures and can be fixed directly to the ground. It is suitable for workshops, warehouses and other places. The foundation requirements are relatively simple and the installation position can be easily adjusted according to the needs of use.

- Efficient operation: The jib rotates 180°–360° for wide coverage. With electric or manual drive, it quickly lifts, moves, and positions goods, improving short-distance transport efficiency.

- Load adaptability: Available in capacities from 0.5 to 5 tons, ideal for light to medium-duty applications.The floor mounted jib crane can transport light materials and lift some heavy equipment.

- High working level: The floor mounted jib crane features heavy-duty (A5) or extra heavy-duty (A6) classification to withstand frequent and high-capacity operations.

- High reliability: Motors and electrical components feature high protection (IP54 or above), making them dustproof and heat-resistant. In addition, key parts like the slewing mechanism are built for exceptional strength and long-term durability.

Solutions

Based on the requirements, Nucleon recommended a 5-ton floor mounted jib crane and completed the design of a customized solution within a week. This 5-ton floor mounted slewing jib crane features a high load capacity, a convenient operating system, an adjustable jib design, and corrosion-resistant materials. Specific specifications are as follows:

- Arm Length: 10 meters

- Load Capacity: 5 tons

- Rotation Angles: 360°

- Power Supply: 380V, 50Hz, 3-phase

- Control method: remote control

- Features: Stable performance and well-designed column structure. Safe and reliable, with safety control systems and components to ensure safety. Easy installation, advanced and concise design, and labor-saving.

Feedback

This 5-ton floor mounted jib crane has improved the steel plant's production efficiency. The customer praised the jib crane's stability and reliability, as well as our professional service. Alvaro, the customer's project manager, said, "The Nucleon Crane team's expertise is truly impressive! This fixed column jib crane mounted slewing jib crane boasts fast lifting speeds and high operating efficiency. The column jib crane also features a designed maintenance platform, making electrical circuit and motor maintenance extremely convenient, saving both time and worry. Nucleon, quality first!"

Project Outcomes

The successful export of this floor-mounted slewing jib crane to a steel mill highlights Nucleon's strengths in customization, technology, service, and logistics. Moving forward, the company will continue to innovate and ensure quality, providing smarter and greener lifting solutions for high-end industries like chemical equipment manufacturing.If you have any needs for gantry cranes, overhead cranes, or other equipment, please feel free to contact us!