The MG double-girder gantry crane has become a mature and reliable lifting solution from Nucleon. It is widely recognized for its exceptional durability, safety, and reliability.

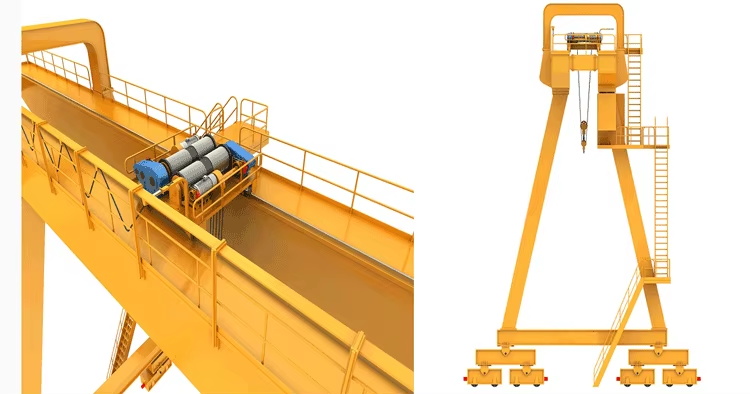

The MG double-girder gantry crane (also known as the MG crane) has become a mature and reliable lifting solution from Nucleon. It is widely recognized for its exceptional durability, safety, and reliability. Featuring a robust double-girder structural design, this equipment offers higher load capacity and stability, making it particularly suitable for cargo lifting and material handling operations in outdoor environments such as freight yards, warehouses, ports, and construction sites. The system incorporates a classic parallel-axis hoisting mechanism and trolley travel mechanism, ensuring smooth operation and precise positioning.

The MG crane is a reliable and efficient solution for outdoor material handling needs. Its robust design, advanced features, and customized options make it a top choice. With a focus on safety, durability, and comfort, the MG gantry crane could deliver outstanding performance in a variety of industrial settings.

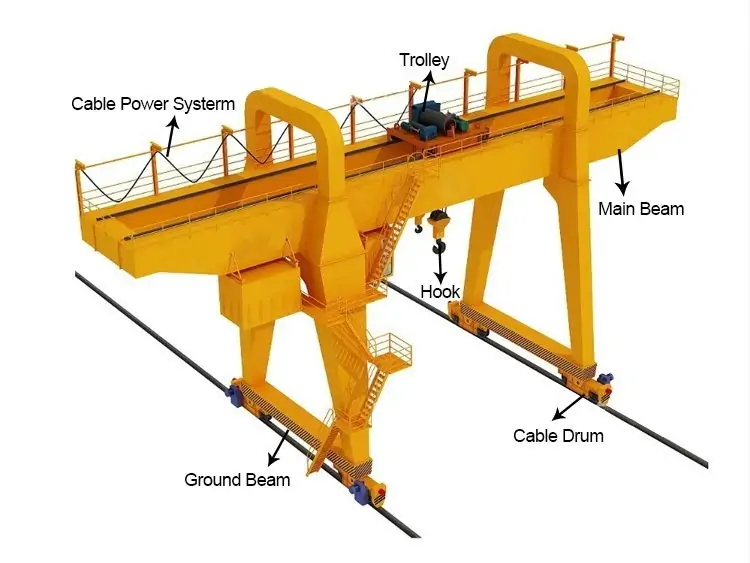

The MG Double Girder Gantry Crane is mainly composed of main girders, end beams, trolley and hoisting mechanism, crane traveling mechanism, electrical system, and control system. Please see this article for details: Gantry Crane Parts

The following are features of each part:

MG Double Beam Gantry Crane is a robust, high-capacity, and versatile heavy-duty lifting equipment widely used in manufacturing, metallurgy, construction, railways, ports, energy, and mining industries. It handles loading, unloading, transporting, and hoisting of large materials outdoors or in factory buildings without رافعات علوية, making it particularly suitable for high-frequency, high-intensity operations.

Below are application scenarios and suitable materials across different industries:

1. Manufacturing Industry

2. Construction Industry

3. Metallurgical Industry

4. Railway & Transportation Industry

5. Port & Shipyard

6. Energy & Power Industry

7. Mining & Heavy Industry

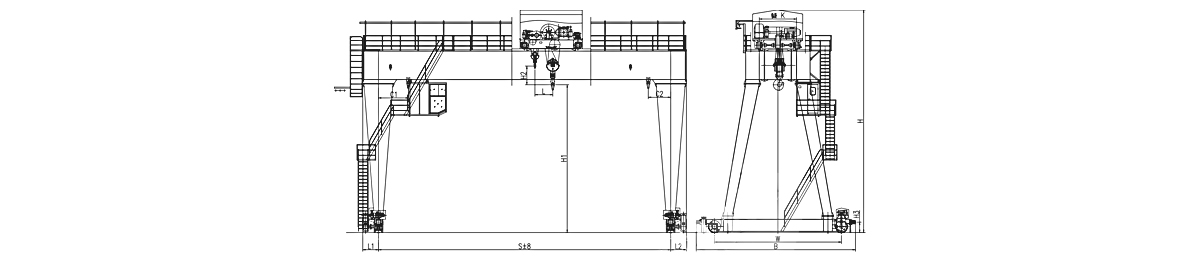

| قدرة الرفع | رئيسي | طن | 5—800 |

| مساعد | 5—80 | ||

| فترة | متر | 18—36 | |

| ارتفاع الرفع | 10—22.5 | ||

| واجب | أ5 | ||

| سرعة | رئيسي | م/دقيقة | 0.1~1 |

| مساعد | 7 | ||

| سفر السلطعون | 0.5~5 | ||

| رافعة السفر | 1~10 | ||

| أقصى تحميل للعجلة | كيلو وات | 650 | |

| إجمالي الطاقة | كيلو وات | 330 | |

| رافعة السكك الحديدية الموصى بها | QU120 | ||

| مزود الطاقة | 3 مراحل تيار متردد 50 هرتز 380 فولت | ||

Nucleon provides customized MG cranes tailored to your specific needs, including lifting capacity, span, and lifting height. The crane’s trolley and gantry can both move along rails for wide-area coverage and flexible operation, suitable for efficient handling of large or heavy materials. Whether used in logistics, construction, or port operations, the MG Double Girder Gantry Crane delivers consistent, high-performance lifting solutions. Contact our team today to discuss your project requirements and get a customized quotation.

Founded in 2005, Nucleon (Xinxiang) Crane Co., Ltd. is a leading gantry crane manufacturer and supplier in China, specializing in the design, production, and installation of various lifting equipment. The company is equipped with more than 3,000 sets of advanced production and testing machines, providing strong technical support for manufacturing high-quality and reliable cranes.

Our products are widely used in metallurgy, energy, power, petrochemical, railway, and aviation industries, and have been exported to markets worldwide. We have rich industry experience and strong R&D capabilities. Nucleon provides customized large gantry crane solutions to meet diverse project requirements, including lifting capacity, span, lifting height, and working environment. Contact our technical team today to discuss your lifting needs and get a customized gantry crane solution that delivers performance, safety, and reliability.

مورد رافعة الرفع الاحترافي، متخصص في تصنيع الرافعات العلوية، والرافعات الجسرية، والرافعات الذراعية والرافعات الكهربائية وما إلى ذلك.

منطقة صناعة الرافعات، مدينة تشانغيوان، مقاطعة خنان، الصين