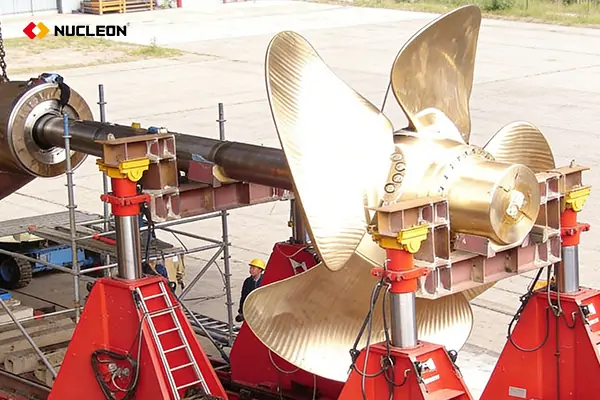

Hydraulic gantry cranes are large lifting equipment driven by hydraulic power. They feature a compact structure and stable operation, supporting precise three-dimensional lifting of heavy objects. They are suitable for heavy-duty applications, providing a safe and efficient solution that is difficult to replace with traditional cranes.

The hydraulic gantry crane, a large-scale lifting equipment centered on a hydraulic transmission system, integrates a gantry frame, hydraulic power unit, lifting trolley, traveling mechanism, and intelligent control system. This equipment offers advantages including high power output, stable operation, and a compact structure. Utilizing guide rails and a lateral shifting device, it enables precise three-dimensional (X, Y, Z) lifting and positioning of heavy loads in a single operation. Suitable for heavy-duty environments such as ports, metallurgy, and bridge construction, the crane delivers an efficient, safe, and flexible lifting solution. It proves particularly valuable where traditional overhead cranes lack the necessary coverage or load capacity.

The key components of a hydraulic gantry crane form a system that works in synergy, and its core elements include:

These components work together precisely, giving the hydraulic gantry crane excellent performance characteristics such as high load capacity, smooth operation, precise control, and strong adaptability.

Smooth and Precise Operation: Stepless speed control, gentle start and stop, stable lifting and lowering control, significantly reducing impact and protecting both the load and the equipment.

Environmentally Friendly and Flexible: Low noise, optional electric or internal combustion engine drive, suitable for various locations with or without a fixed power supply.

Simple and Economical Maintenance: High standardization and interchangeability of hydraulic components, independent system, reducing clutter of on-site pipelines, and resulting in low maintenance costs.

| اسم المنتج | Hydraulic Gantry Crane |

| Rated Load Capacity | Standard Range: 5 - 1000 Ton Typical Grades: Grade 1: 612T / Grade 2: 509T / Grade 3: 377T |

| فئة الواجب | أ6 |

| فترة | 8 - 35 m (Customizable) |

| ارتفاع الرفع | 4.5 - 10.6 m (Customizable) |

| Core Structure & Drive | Telescopic Main Girder + Hydraulic Legs (2/4 legs config.) Rail Traveling Mechanism (Trackless option available) Electro-Hydraulic Synchronous Drive System |

| Operation & Control | Single-person wireless remote control (Standard) / Pendant control (Optional) Intelligent wireless synchronization control system |

| Main Power Supply | AC 380V, 50Hz, 3-Phase (Customizable) |

| Installation & Packaging | Modular design, on-site professional assembly, Wooden/Frame case packaging |

| Operating Environment | Ambient Temperature: -20℃ ~ +50℃ |

| Warranty | 18 Months (Subject to contract) |

As a leading manufacturer of hydraulic gantry crane systems in China, Nucleon focuses on providing highly customized lifting solutions for our customers. We can design and manufacture hydraulic gantry crane systems to meet your specific application scenarios and operational requirements, including customized configurations of core parameters such as lifting capacity, span, and working class.

For business inquiries or technical consultations, please feel free to اتصل بنا. We will be happy to provide you with professional support.

مورد رافعة الرفع الاحترافي، متخصص في تصنيع الرافعات العلوية، والرافعات الجسرية، والرافعات الذراعية والرافعات الكهربائية وما إلى ذلك.

منطقة صناعة الرافعات، مدينة تشانغيوان، مقاطعة خنان، الصين