20 ton gantry cranes are widely used in material handling applications such as factory workshops, warehouses, construction sites, ports and railway freight yards.

20-ton gantry cranes are widely used in material handling applications such as factory floors, warehouses , construction sites, ports, and railway freight yards . 20-ton gantry cranes offer a variety of structural designs, adapting to most material handling scenarios. If you have specific needs, Nucleon also offers a range of customized services to meet your requirements.

The sturdy and durable 20-ton gantry crane is composed of a variety of accessories, which have different functions and each accessory is indispensable.

The most critical lifting component of a 20-ton crane. Use the hook to pick up and place loads, and the hinge and steel rope to adjust the height of the material.

The horizontal moving part can slide along the main beam track. Its main function is to drive the electric hoist to adjust its horizontal position and expand the coverage of materials.

Gantry crane controllers are generally divided into wireless remote controls and cab controls. The wireless remote control allows for remote automated operation of a 20-ton crane, making it safer and more efficient. Technicians can also perform more complex and specialized equipment operations from within the cab.

Safety devices include limiters to prevent the crane and trolley from exceeding their travel range, brakes for emergency stop, and overload sensors to prevent overloading . All safety devices comply with relevant standards to prevent accidents from occurring or escalating.

According to different structural designs and application scenarios, 20-ton gantry cranes are mainly divided into the following types:

Structural features : single main beam + electric hoist trolley, simple structure , light weight and small footprint.

Span range : 27 meters; lifting height: 9-12 meters

Applicable scenarios : Suitable for medium and light load operations in workshops, warehouses, small docks , etc.

Core advantages : low cost, easy installation, small footprint

Structural features : Double main beams + trolley with hook/electric hoist, strong rigidity and good stability.

Span range : 28 meters; lifting height: 6-20 meters

Applicable scenarios : Suitable for large factories, ports, construction sites

Core advantages : strong carrying capacity, adaptable to high-frequency operations . Can be equipped with auxiliary hooks to achieve double-load operations.

Structural features : One side has legs (running along the ground track), the other side relies on the building wall (running along the elevated track)

Span range : 12-25 meters; lifting height: 6-15 meters

Applicable scenarios : small warehouses, factory assembly lines

Core advantages : Saves ground space; suitable for working along building walls.

Structural features : removable main beam + rubber tire (no need for fixed track)

Span range : 8-18 meters; lifting height: 5-10 meters

Applicable scenarios : temporary lifting operations such as construction sites, maintenance workshops, and outdoor cargo yards

Core advantage : Fast movement speed, can quickly change positions in the work environment.

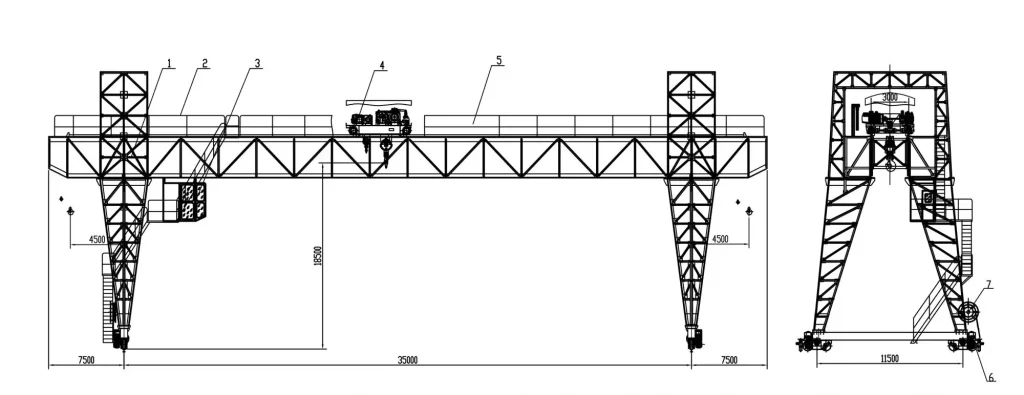

Structural features : The main beam adopts a truss structure (welded from steel sections into triangular/trapezoidal trusses), and the legs are mostly lattice-shaped designs.

Span range : 15-35 meters; lifting height: 8-22 meters

Applicable scenarios : Suitable for windy scenarios, such as ports, coastal mines , etc.

Core advantages : The truss structure is light in weight , quick to install, has low wind resistance, and is suitable for outdoor operations.

Structural features : The outriggers are arranged in an L-shaped pattern, with one end of the main beam connected vertically to the L-shaped outriggers, and the other end extending to the edge of the working area (without outrigger obstruction).

Span range : 27 meters ; lifting height : 8-16 meters

Applicable scenarios : used for transporting long strips of materials or large-volume goods .

Core advantage : The special gantry structure can ensure the passage space of goods and also reduce the deadweight of the 20-ton gantry crane.

| Crane type | price | المدى (م) | ارتفاع الرفع (م) | Work Scene | Power supply mode | الطبقة العاملة |

| Single beam 20 ton gantry crane | $44,000 | 9 | 6 - 12 | Workshops, warehouses, manufacturing plants | 380V, 50Hz three-phase AC | A4, A5 |

| Double-girder 20-ton gantry crane | $102,000 | 8 - 20 | 8 - 20 | Ports, factories, large warehouses | 380V, 50Hz three-phase AC | A5, A6 |

| Semi-gantry 20-ton gantry crane | $60,000 | 30 | 6 - 15 | Factories or warehouses with limited width, above the assembly line | 380V, 50Hz three-phase AC | أ5 |

| Mobile 20-ton gantry crane | $30,000 | 8 - 18 | 5 - 10 | Outdoor cargo yard, construction site | 380V, 50Hz three-phase AC | أ4 |

| Truss type 20 ton gantry crane | $40,000 | 30 | 8 - 22 | Windy venues | 380V, 50Hz three-phase AC | أ5 |

| L-type 20-ton gantry crane | $74,000 | 28 | 7 - 18 | Transshipment of large cargo | 380V, 50Hz three-phase AC | أ5 |

| Specification item (Item) | Parameter data (Data) |

| Rated lifting capacity (Capacity) | 20 tons |

| فترة | 8 - 30 meters |

| ارتفاع الرفع | 6 - 20 meters |

| سرعة الرفع | 0.5 - 10 m/min |

| Cross travelling speed | 10 - 40 m/min |

| Long travelling speed | 20 - 60 m/min |

| الطبقة العاملة | ISO A3 - A6 / FEM 1AM - FEM 3M |

| مصدر الطاقة | Standard 380V, 50Hz three-phase AC |

Nucleon is a gantry crane manufacturer and supplier with 20 years of production and R&D experience and a team of professional engineers. We offer custom design services for a variety of crane types, including RTG gantry cranes, lattice gantry cranes, and semi-gantry cranes. If you are interested in purchasing a 20-ton gantry crane, please contact us for solutions and a quote.

مورد رافعة الرفع الاحترافي، متخصص في تصنيع الرافعات العلوية، والرافعات الجسرية، والرافعات الذراعية والرافعات الكهربائية وما إلى ذلك.

منطقة صناعة الرافعات، مدينة تشانغيوان، مقاطعة خنان، الصين