An RMG crane (Rail-Mounted Gantry Crane) is a heavy-duty lifting equipment designed for efficient material handling in ports, intermodal yards, and large industrial facilities. It operates on fixed rails, providing high precision and stability for lifting and transporting heavy containers, steel coils, and other bulky cargo. RMG cranes have robustness, automation capabilities, and ability to optimize storage space in confined areas.

In this article, we will explore the definition, types, structure, and working principles of RMG cranes to help you gain a deeper understanding of this essential equipment. Continue reading to learn more about RMG cranes and their applications!

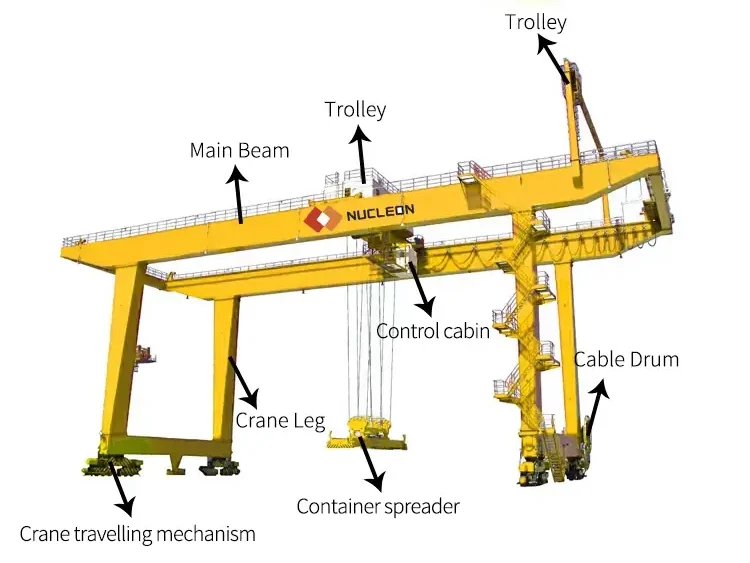

RMG Crane Parts

The RMG Crane primarily consists of core components such as a steel structure frame, hoisting mechanism, main crane running mechanism, trolley running mechanism, electrical system, and safety devices.

- Steel Structure Frame: Constructed using high-strength steel welded together, it provides stable support and withstands dynamic loads.

- Hoisting Mechanism: Comprising a motor, reducer, steel wire rope, and lifting device, it enables precise vertical lifting control.

- Main Gantry Travel Mechanism: Drives the entire machine along the track, equipped with a dual-track synchronous system to ensure smooth operation.

- Trolley Travel Mechanism: Controls the lateral movement of the lifting device, optimizing container positioning efficiency.

- Electrical System: Integrated with PLC and variable frequency control, supporting automated operations and energy management.

- Safety Devices: Includes limit switches, collision prevention systems, and load sensors to ensure operational safety.

How does RMG Crane Work?

An RMG crane operates on fixed rails, enabling precise horizontal and vertical movement for heavy-load handling. It consists of a steel gantry frame, a trolley with a hoisting mechanism, and end carriages that travel along the rails. The crane lifts containers or cargo using spreaders or hooks, then transports them along the rail system for stacking or transfer. RMG cranes can be manually operated, semi-automated, or fully automated, integrating with terminal management systems for optimized logistics.

Common Types of RMG Cranes in Ports

RMG cranes are important equipment in ports, railway yards, and logistics centers, primarily used for the efficient handling and stacking of containers and heavy cargo. Based on their structure and functionality, RMG cranes in ports are primarily categorized into the following types:

1. Standard RMG Crane: Operates on fixed tracks, covering specific areas of container yards. The lifting height is typically “1 over 4” or “1 over 5,” meaning it can stack 4–5 layers of containers. It is generally suitable for container loading, unloading, and storage operations in medium-sized and small ports and railway container transshipment stations.

2. Elevated RMG رافعة: The tracks are mounted on elevated platforms, enabling them to span truck or train lanes and minimize ground interference. Suitable for hub ports and automated terminals requiring high-density storage, they can operate in conjunction with AGVs (automated guided vehicles) or straddle carriers.

3. Double Cantilever RMG رافعة: Features cantilevers on both sides, enabling simultaneous service for railway and truck loading/unloading to enhance operational efficiency. Suitable for multimodal transportation hubs to reduce equipment movement time, such as sea-rail intermodal ports and container yards requiring rapid transshipment.

4. Automated RMG, ARMG رافعة: Utilizes unmanned operation, scheduled by a central control system (TOS), to reduce labor costs. Equipped with laser positioning + OCR (optical character recognition) for precise container handling. Suitable for modern smart ports, such as automated terminals and high-efficiency ports requiring 24/7 continuous operation.

5. Low-Profile RMG رافعة: Compact structure, suitable for space-constrained yards or indoor warehouses. Lower lifting height but stable operation, suitable for medium and small-sized logistics centers. Examples include inland container yards, bonded warehouses, or logistics parks.

المزايا

- High Efficiency: Automated operation enables fast, precise container handling, reducing turnaround time in ports and terminals.

- Space Optimization: Moves on fixed rails, maximizing vertical stacking density and minimizing ground space usage.

- Heavy Load Capacity: Loading capacity up to 100+ tons, ideal for containers, steel coils, and bulk cargo.

- Enhanced Safety: Reduced human intervention lowers accident risks, with features like anti-sway and collision avoidance systems.

- Low Operating Costs: Energy-efficient motors and automated systems reduce labor and maintenance expenses.

- Weather Resistance: Robust construction ensures reliable performance in harsh environments (wind, rain, extreme temperatures).

- Customizable Automation: Can integrate with terminal management systems (TOS) for seamless logistics operations.

Rail Mounted Gantry Crane Price Price

The price of RMG cranes is determined by several key technical specifications, which directly affect design complexity and manufacturing costs. The primary factors include: lifting capacity (determining structural requirements), span length (affecting beam design and support systems), lifting height (affecting hoisting mechanisms and mast structures), duty cycle (A1-A8 classification affecting component durability), automation level (from manual to fully automated systems), and custom features (such as special coatings, sensors, or advanced control systems). These variables collectively determine the final investment required for your material handling solution.

| Capacity | Span Range | ارتفاع الرفع | فئة الواجب | Price Range |

|---|---|---|---|---|

| 20 Ton | 18-25m | 9-12m | A4-A5 | $180,000-$240,000 |

| 35 Ton | 25-35m | 12-15m | أ5-أ6 | $300,000-$370,000 |

| 45 Ton | 30-40m | 15-18m | A6-A7 | $380,000-$440,000 |

| 60 Ton | 35-45m | 18-22m | A7-A8 | $450,000-$520,000 |

Prices exclude installation and transportation

Lead time typically 3-6 months

5% discount available for orders over 3 units*

For precise quotations with your exact specifications, please contact our sales team with your project requirements. We offer competitive pricing and ensure quality or safety standards.

خاتمة

In summary, RMG cranes are indispensable handling equipment for modern ports, railway yards, and logistics hubs. They feature high efficiency, stability, and automation, effectively enhancing the handling efficiency of containers and heavy cargo. Depending on specific operational requirements, customers can choose from various customized structural types, including standard, elevated, double-boom, fully automatic, and low-clearance models.

Nucleon offers professional technical consulting, customized solution design, and cost-effective quotation services. For RMG selection recommendations or customized solutions, please feel free to contact us for consultation.

Contact us now for professional support! (Email: [email protected], WeChat: +8613673512179)