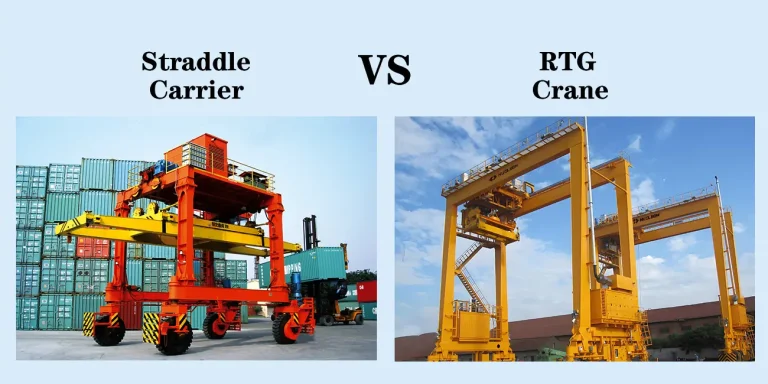

At container terminals, besides the busy quay cranes operating between ships and shore, various types of lifting equipment are constantly moving about in the container yard. Among them, straddle carriers and rubber-tired gantry cranes are two of the most core and common yard operation equipment. They seem to have similar functions, both used for stacking and moving containers in the yard, but what are the differences between them? Why would a terminal use both or choose one of them?

This article will delve into the differences between the two, from their definitions and functions to their applicable scenarios, to help you make the best lifting choice.

What is a straddle carrier?

A straddle carrier is a specialized piece of equipment used in ports and logistics centers for handling and stacking large cargo (such as containers). Its core feature is its unique gantry structure, allowing it to operate directly across cargo bays, integrating horizontal transport and vertical stacking functions for rapid cargo transfer and efficient storage.

Core Functions and Advantages:

High Efficiency Integration: Integrating loading, unloading, transport, and stacking functions, it enables rapid cargo turnover and significantly improves site operation efficiency.

Mobile and Flexible: Thanks to its unique straddle structure, it can move flexibly within limited spaces and adapt to various road conditions, from flat docks to rugged construction sites.

Economical and Environmentally Friendly: Modern design prioritizes low energy consumption and low maintenance requirements, significantly reducing operating costs and aligning with green operation trends.

What is an RTG Crane?

A rubber-tired gantry crane (RTG) serves as the core equipment in container yards. It is designed to stack and transfer containers with high efficiency and density. The crane features a tall gantry structure that moves on rubber tires. This design provides good mobility across the yard, allowing it to shift between different container blocks. However, unlike straddle carriers, an RTG typically operates within a relatively fixed area.

Core Functions and Features:

High Load Capacity: Capable of stably lifting and handling heavy containers weighing over 40 tons, meeting the handling needs of modern large ports and logistics hubs for heavy cargo.

High-Density Stacking: Supports vertical stacking of 4 to 6 layers of containers, significantly improving yard space utilization and suitable for high-volume operation scenarios with limited land resources.

Flexible Operating Modes: Supports multiple control methods, including cab operation, ground wireless remote control, and automated systems, adapting to different operational processes and efficiency requirements.

Strong site adaptability: Relying on the tire-type walking mechanism, it can flexibly move between yard aisles and is widely used in ports, railway container stations, logistics parks and large construction sites, capable of handling high-intensity and high-frequency container scheduling and storage tasks.

Key Differences: Straddle Carrier vs. Rubber-Tyred Gantry Crane

| Aspect | Straddle Carrier | Rubber-Tyred Gantry Crane (RTG) |

| Core Function | Integrates horizontal transport and stacking. Excels at direct, point-to-point container movement. | Specializes in vertical stacking, container shuffling, and truck loading/unloading within the yard. |

| Mobility & Flexibility | High. Self-propelled on rubber tires, offering high agility and quick transfer between different work areas. | Limited. Mobile on tires but moves slowly with a large turning radius. Operates within a relatively fixed yard block. |

| Operational Efficiency | Highly efficient at short-distance transport, enabling rapid ship/truck turnaround. Stacking height is limited (typically 2-3 high). | Exceptional stacking efficiency and density (typically 5-6 high). Requires truck coordination for transport, adding process steps. |

| Weather Resilience | Better. A lower profile reduces wind exposure, allowing operation in more adverse weather conditions. | Poorer. The tall portal structure is vulnerable to strong winds, often requiring operation slowdown or shutdown for safety. |

This table clearly shows the fundamental differences between the two in terms of functional positioning and operating mode: straddle carriers pursue process integration and flexibility, while RTGs focus on space utilization and stacking efficiency.

Analysis of the Advantages and Disadvantages of Straddle Carriers and RTGs

I. Straddle Carriers

Advantages:

Excellent mobility: Relatively compact size and agile steering, ideal for operations in spaces with limited space and narrow aisles.

Highly adaptable to layout: Quickly responds to changes in work processes and storage areas without requiring site modifications, offering high flexibility and low conversion costs.

Disadvantages:

Limited load capacity: Not suitable for handling overweight or oversized cargo.

Higher operating costs: Due to frequent movement and complex structure, components wear out quickly, leading to higher maintenance frequency and costs, as well as relatively higher energy consumption.

II. Rubber-Tired Gantry Cranes (RTG)

Advantages:

High load-bearing capacity and stable operation: Designed specifically for heavy containers, with a robust structure, low failure rate, and high reliability.

Simple maintenance and management: Maintenance cycles are relatively regular and concentrated, facilitating planning and reducing management costs.

Disadvantages:

Insufficient flexibility: The operating range is limited by its travel trajectory, making rapid adjustments difficult and unable to adapt to sudden changes in operational demands.

Poor wind resistance: The tall gantry structure necessitates slowing down or stopping operations in strong winds or other severe weather conditions, significantly impacting efficiency and safety.

Choose a straddle carrier if your site has limited space, fast cargo flow, and frequent layout changes. It offers high mobility and combines transport with stacking in one process. Alternatively, select a Rubber-Tyred Gantry Crane (RTG) if you operate in a fixed yard with high cargo volumes. The RTG provides high stability, stacks containers higher, and lowers your operating costs, maximizing land use and storage density.

خاتمة

Understanding the key differences between straddle carriers and rubber-tired gantry cranes is crucial when selecting equipment. Both have their advantages and disadvantages, and businesses must comprehensively consider their actual operational needs when choosing equipment, such as the size of the work site, the type and weight of the cargo, the complexity of the operational process, and the requirements for operational efficiency and cost.

Nucleon Crane focuses on providing professional port and logistics handling solutions. If you require more detailed technical data or customized consulting advice in equipment selection, our team of experts is ready to serve you, helping you choose the most suitable equipment to maximize operational efficiency and economic benefits.