How to use overhead crane is a core skill related to efficiency and production safety in large-scale construction projects such as industrial production and warehousing materials. Overhead cranes with their strong load capacity and a wide operating range, and have become the preferred solution for lifting heavy objects and optimizing space in various industries. However, operating an overhead crane is not an easy task. Improper operation will not only damage expensive equipment and cargo, but may also cause serious casualties. Next, we will take a deep look at how to use overhead crane, items that need to be checked before use, and safety rules for overhead cranes. Helps you understand how to use overhead cranes to improve safety in your production environment.

What Is An Overhead Crane?

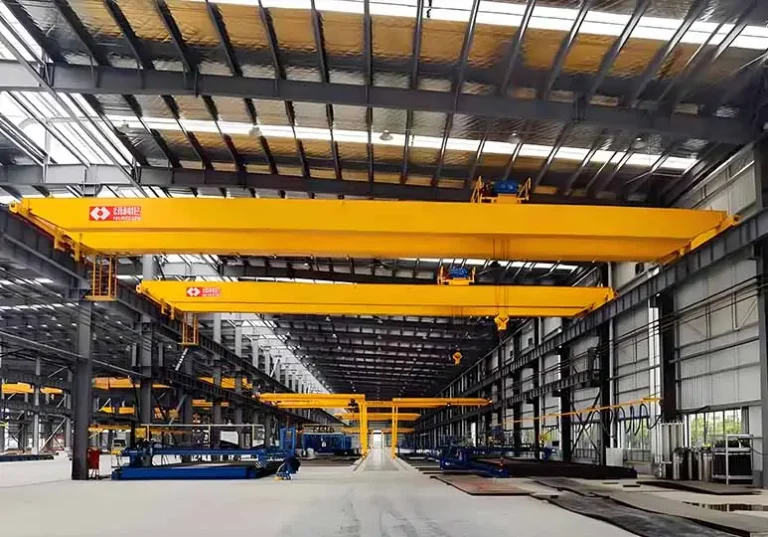

An overhead crane is a type of lifting equipment widely used above workshops, warehouses, and material yards, and is mainly used for lifting materials. Its structural feature is that it spans above the working area, with both ends built on concrete columns or steel structure brackets, and its overall shape resembles a bridge, so it is also commonly known as a "bridge crane" or "overhead traveling crane". Under normal circumstances, the load capacity of bridge cranes ranges from 1 to 320 tons.

How To Use Overhead Crane?

Mastering the correct and standardized use of overhead cranes is the key to ensure production safety and efficiency. Operators not only need to understand the working principles of the equipment but also need to be familiar with and strictly abide by safe operating procedures, understand the functions and status of key components, and conduct detailed inspections before and after each operation.

Overhead Crane Operation Safety Rules

When using overhead cranes, one should abide by the following safety rules:

- The overhead crane shall be operated by personnel who meet the professional special equipment driving qualification certificate.

- The side of the equipment must be marked with the bridge crane's maximum load, span, working level, and other information.

- No people are standing on the bridge crane except in the cabin.

- When the EOT crane is undergoing routine inspection and maintenance, the entire vehicle must be powered off.

- When the EOT crane is not loaded, the hook should be at least 2.5 meters above the ground to maintain a safe distance.

- It is prohibited for overhead cranes to pass over the heads of people on the ground when transporting goods.

- For an overhead crane, the lowest point of the load shall be 0.5m higher than the highest point of obstacles.

- People transportation on a hook is not allowed.

- Tools, spare parts, fasteners, and varia should be in special cases, they are not allowed to be placed on the EOT crane to avoid dropping objects, hurting, or damaging equipment.

- When lifting an expensive load or noxious liquid, no matter how heavy it is, only after checking reliability on the position above ground 150-200mm, can the overhead crane keep lifting.

- Combustibles are not allowed to be positioned on the bridge crane, fire prevention should be considered.

- Wind force is more than class 6, stop using the crane outdoors.

- Give the EOT crane a periodic routine inspection that includes dynamic and static load tests, and the results should be documented.

Notice: Drivers should strictly abide by and implement the above safety regulations.

What Are The Parts Of An Overhead Crane?

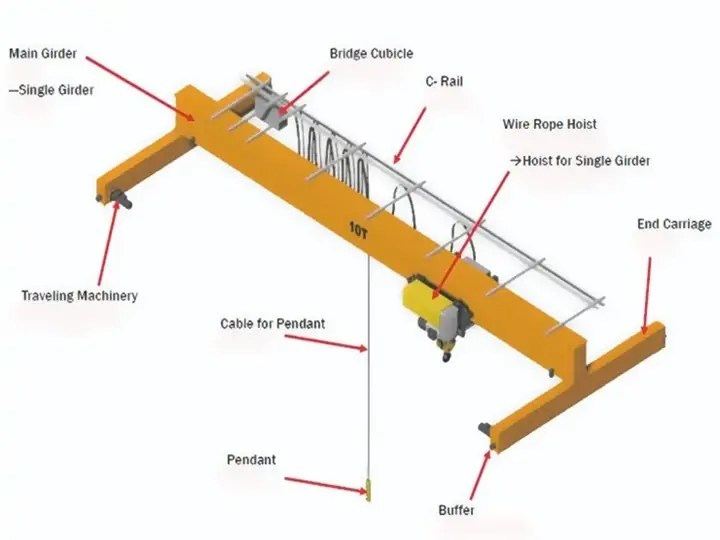

An overhead cranes consist of one/two parallel main girders, end girders, a hoisting mechanism, an electrical system, a safety device, a trolley running mechanism, and other parts. The main girders are connected by cross girders to form a stable frame structure. The hoisting mechanism is usually mounted on the trolley, which runs along the upper flange of the main girder and is capable of carrying larger tonnage loads. Overhead cranes are suitable for heavy material lifting, with the advantages of high stability and strong load carrying capacity.

Are hard hats required for overhead crane use?

It is necessary to wear a safety helmet when use overhead crane. The operating environment of a bridge crane is a high-risk area, with the risk of falling objects and head collisions. As a simple and effective protective equipment, a safety helmet can significantly reduce the probability of head injuries. Therefore, whether it is an operator, commander, assistant, or anyone who needs to enter the working area of a bridge crane, they must always wear a standard safety helmet correctly.

Overhead Crane Pre Use Inspection Checklist

Inspection of the use of overhead cranes is extremely important. It is the first line of defense to ensure production safety and prevent accidents. It must be carefully inspected by professional technicians before each use. Usually, including the following key aspects:

Safety devices: Check whether the safety devices, such as brakes, limiters, emergency brake switches, etc,. They are operating normally.

Mechanical part: Check the bridge deck, wire ropes, hooks, pulleys, rails and other mechanical parts for deformation, cracks, corrosion and other conditions.

Electrical part: Check the operating handle/remote control, cables, busbars, and instrument panel for obvious signs of dust accumulation or circuit damage.

Surroundings: Check for obstacles and personnel under and around the crane's path, and ensure that the route has sufficient safe space and lighting.

conclusion

The above content introduces how to use overhead crane and the rules and regulations for using overhead cranes. Mastering the standardized operation of how to use overhead cranes is the key to safe production and improving work efficiency. Nucleon As a professional crane Customization and manufacturer, committed to providing high-performance and high-reliability lifting equipment to help you effectively improve your production efficiency.

For customized overhead crane solutions, please feel free to contact us. Nucleon's professional team will provide you with personalized advice and help you choose the most suitable equipment.