Gantry cranes are essential material handling equipment in modern industrial systems . Different models and types of gantry cranes are used in different applications and are suitable for handling different cargoes. Only by choosing the right crane can you maximize the efficiency of the equipment. This article will introduce several common gantry crane types to help you gain an understanding of gantry cranes and choose the one that best suits your needs.

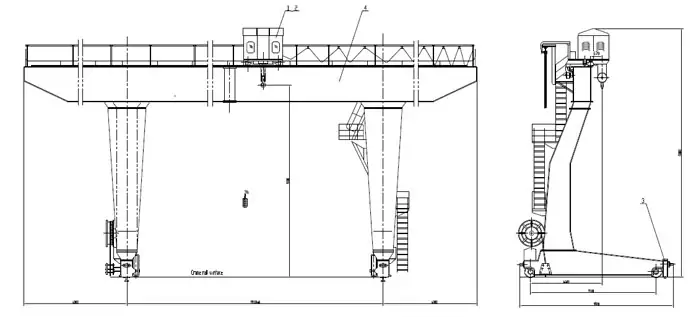

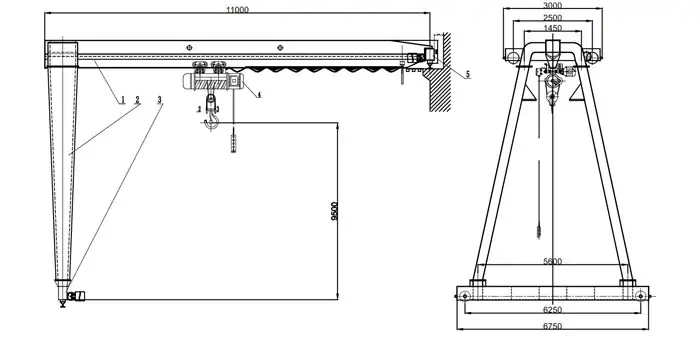

L-type gantry crane

The core design highlight of the L-shaped gantry crane lies in its single-sided L-shaped outrigger, which perfectly conforms to the shape of long, irregular cargo, preventing it from shifting or slipping during handling. The overall weight of the equipment is relatively low, and the operating mechanism ensures smooth movement. Combined with a precise positioning system, it can quickly pick up and place cargo without the need for additional fixing devices.

المزايا

Excellent cargo adaptability: specially designed for long and special-shaped materials, it can be put into use directly without modification, reducing preparation time before operation.

Flexible and efficient operation: It is light in weight, has quick response in starting and braking, and can be flexibly adjusted in the working area to meet high-frequency handling needs.

Strong cost controllability: The structure is relatively simple, and the manufacturing and maintenance costs are low, making it suitable for small and medium-sized enterprises or special material handling scenarios.

Application Scenario

Widely used in freight yards, warehouses, and building material processing workshops, the platform efficiently transports long materials like rails and steel pipes in freight yards, facilitates the storage and retrieval of long mechanical parts and profiles in warehouses, and facilitates the handling and transition of rebar and aluminum alloy profiles to production lines in building material processing workshops.

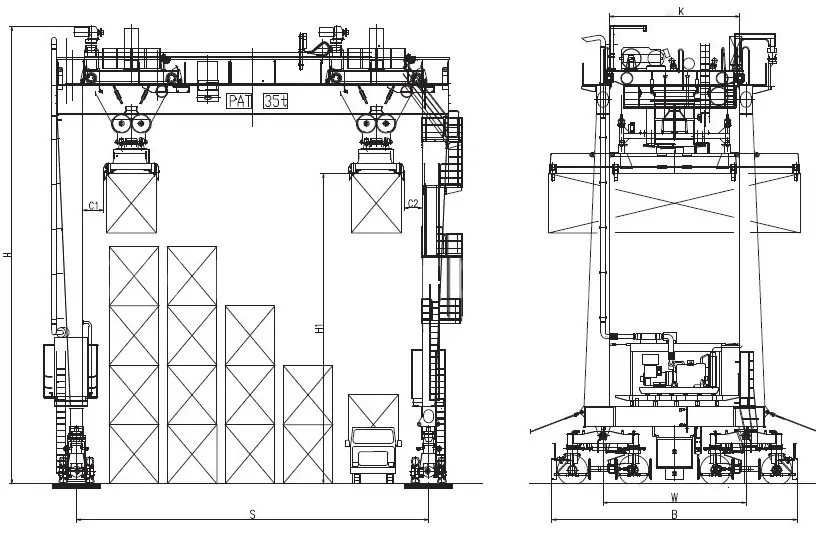

RTG Crane

RTG cranes utilize rubber tires as their mobile carrier, freeing themselves from the constraints of fixed rails and enabling them to turn and maneuver freely within the container yard. Equipped with a container grabbing device, they precisely align with container corner fittings for more stable gripping, and can adjust their operating pace based on yard traffic.

المزايا

Strong site adaptability: No need to lay fixed tracks, the operation route can be adjusted according to the yard layout, and the position can be quickly moved and adjusted, which is suitable for temporary expansion or layout modification.

High operating efficiency: Combining a dedicated gripping device with an adjustable speed design, a single device can complete dozens of container loading, unloading or stacking operations per hour, significantly improving the yard turnover rate.

Easy operation and maintenance: Tires are easy to replace after wear, and the core components adopt a modular design, which shortens troubleshooting and repair time and reduces equipment downtime.

Application Scenario

RTG cranes are primarily used in port container yards and inland container transshipment stations. At ports, they connect ships and transport vehicles to complete container unloading, storage, and loading operations. At inland transshipment stations, they facilitate cross-modal container transfers between trucks and trains, ensuring smooth logistics.

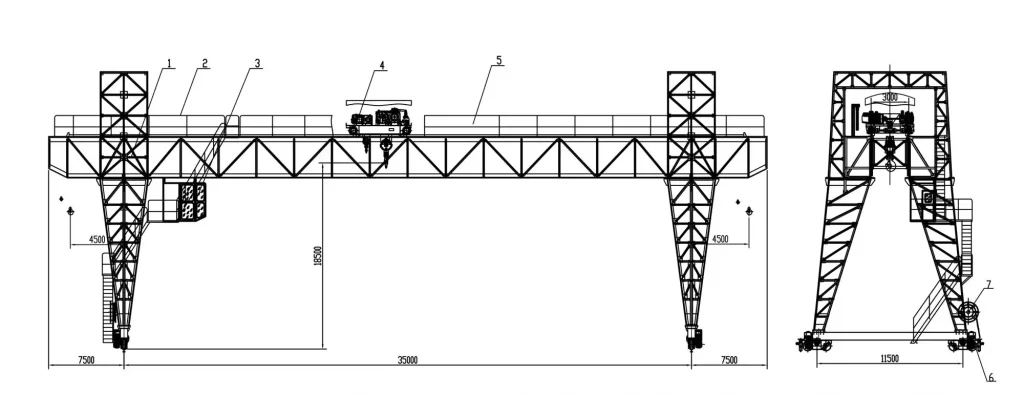

Truss gantry crane

The main beam and outriggers of truss gantry cranes utilize a truss structure, distributing the load through staggered members. This ensures high-strength support while significantly reducing the weight of the equipment. The surface of the equipment is treated with an anti-corrosion and rust-proof treatment to withstand outdoor erosion, such as rain and salt. The truss structure also offers excellent wind resistance, ensuring stable operation even in strong winds.

المزايا

Strong structural stability: The truss structure has outstanding anti-deformation ability and can withstand the long-term demand of heavy cargo handling to ensure operational safety.

Good wind resistance : The truss design can greatly reduce the impact of strong winds at high altitudes, allowing operations at higher altitudes to be carried out safely. Truss gantry cranes are suitable for installation in windy places such as open-pit mines .

Low energy consumption: It has a light weight and a small motor load during operation. Compared with other types of cranes of the same tonnage, it can save a certain amount of energy costs in long-term use.

Application Scenario

It is mainly used in shipyards, waste treatment plants, and open-pit mines . In shipyards, it can lift large components such as hull sections and engines; in waste treatment plants, it can grab heavy materials such as scrap steel and scrap metal; in open-pit mines , it can grab mineral materials and slag.

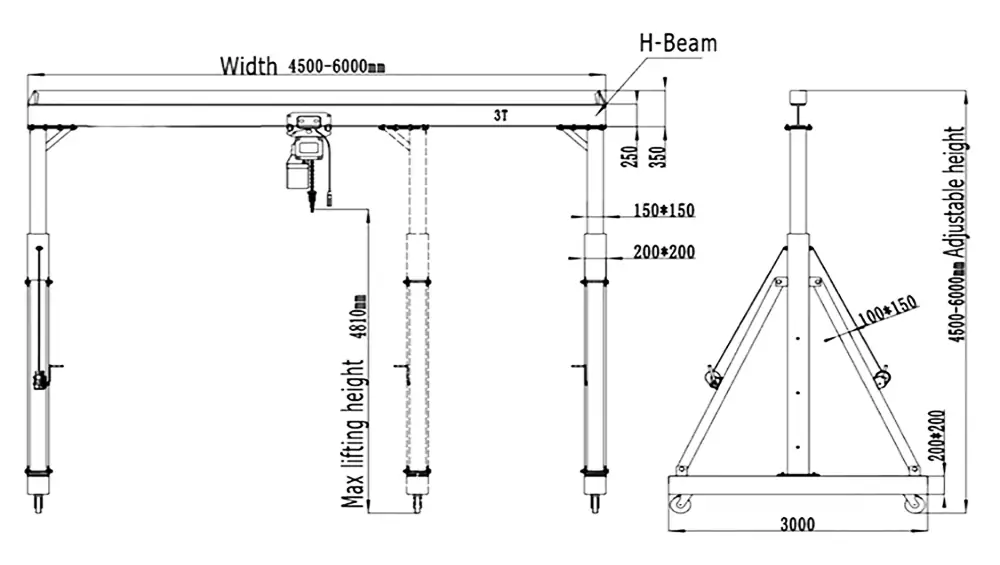

Adjustable gantry crane

The crane's height and span can be adjusted manually or electrically, allowing for quick adaptation to cargo of varying sizes and spaces . Its compact structure saves storage space when idle and allows for quick movement to change workspaces .

المزايا

High versatility: One device can replace multiple cranes of fixed specifications, and can handle both small mechanical parts and larger equipment components, reducing equipment procurement costs.

High space utilization: The machine can adjust its parameters according to the height and width of the operating area, and can operate efficiently even in space-constrained scenarios such as low warehouses and narrow workshops.

Low operating threshold: The adjustment device is simple and efficient , and operators can get started after simple training, reducing manpower training investment.

Application Scenario

It's ideal for machinery factories with varying cargo sizes, maintenance workshops with limited space, and multi-category warehouses. In machinery factories, it can coordinate with production lines to handle semi-finished and finished products of varying sizes; in maintenance workshops, it can assist with the disassembly, assembly, and hoisting of large equipment; and in multi-category warehouses, it can accommodate the storage and retrieval needs of goods on shelves of varying heights.

Semi-gantry crane

Semi-gantry crane adopts a hybrid structure of "single-sided leg + single-sided building support". One side of the leg moves on the ground through wheels or tracks, and the other side is fixed with the help of building columns or walls, eliminating the need to lay two ground tracks.

المزايا

Significant space saving: Only one ground track is required, which greatly reduces the ground space occupied and is suitable for places with narrow workshop aisles and compact storage areas.

Low installation cost: No large-scale site reconstruction is required, and existing building structures can be used for support, reducing investment in infrastructure construction.

Good operating stability: The single-sided building support enhances the equipment's ability to resist rollover, and can prevent shaking during operation even when carrying heavy cargo.

Application Scenario

It is often used in outdoor storage areas adjacent to factory buildings and production workshops with limited floor space. In outdoor storage areas, the factory walls can be used for support, allowing for the temporary storage and transfer of raw materials and finished products. In production workshops, it can facilitate the transfer of materials over large spans while minimizing disruption to production line layout , improving the continuity of workshop operations.

خاتمة

gantry crane you choose depends on the specifications of the cargo being transferred and the worksite environment. Choosing the right gantry crane not only ensures work safety but also improves transfer efficiency. If you are struggling with low site efficiency and your existing equipment is insufficient to meet your needs, contact Nucleon. Our professional team can provide customized gantry crane solutions based on your operating scenarios, cargo parameters, and production capacity targets, helping you improve the quality and efficiency of your production processes.