Electric overhead cranes are workhorses in industrial applications, capable of lifting heavy loads precisely and efficiently. They are widely utilized in factories, warehouses, steel mills, and assembly plants. The safe and stable operation of these cranes is extremely crucial for industrial production. This article provides a guide on the routine maintenance and operation of EOT cranes, helping users gain a better understanding and implement these procedures effectively.

Electric overhead cranes are responsible for lifting heavy loads, and any malfunction can be life-threatening. Properly maintained cranes not only reduce the risk of accidents but also extend the equipment's lifespan and ensure consistent performance. From electrical system failures to wire rope wear, even the smallest issues can quickly worsen if not addressed promptly, making proactive maintenance essential.

Maintenance parts of the EOT Crane

EOT Crane Parts Maintenance Catalogue

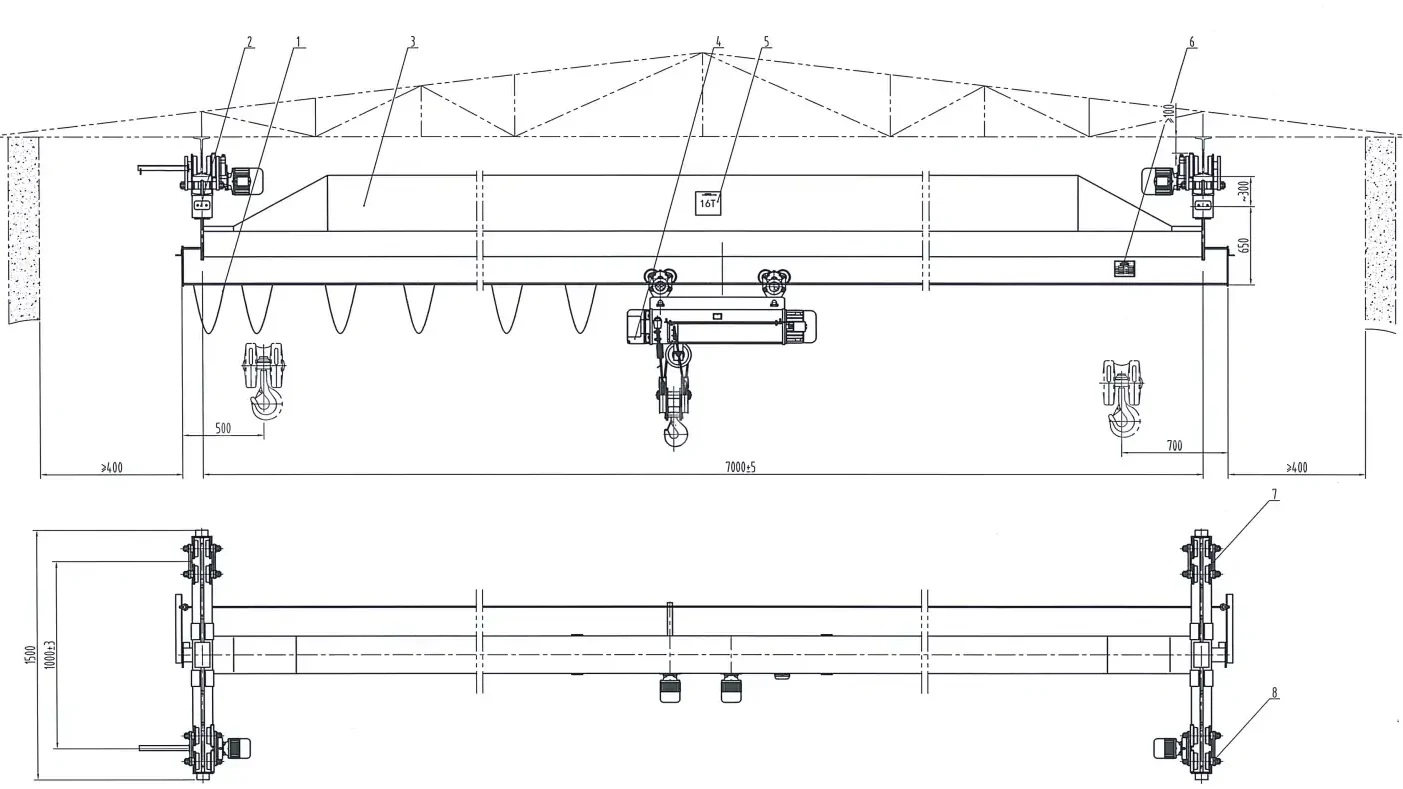

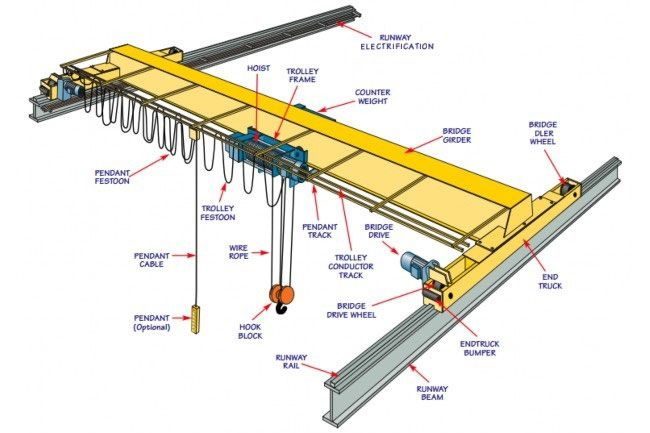

EOT Crane Design

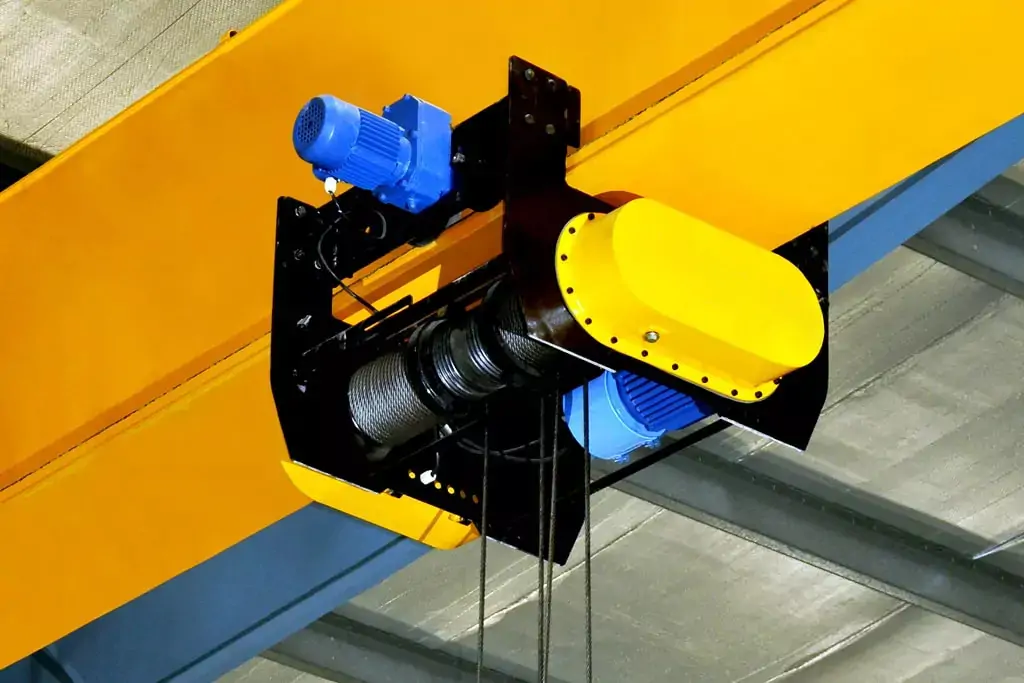

The stable operation of a crane depends on the maintenance of key components. The bridge must be inspected for connector tightness and deformation to prevent collapse. Trolleys must pay attention to track lubrication and wheel wear to ensure smooth lateral movement. Hoists must pay attention to drum wear and bearing lubrication to prevent heavy objects from falling. The end beams must maintain axle clearance and braking performance to prevent offset and jamming. The control system must calibrate the sensor and line insulation to eliminate command delays or false operations. Safety devices such as buffers must ensure sensitive triggering and normal reset to prevent collisions. The maintenance of these components is interrelated and works together to ensure safe and efficient operation of the equipment.

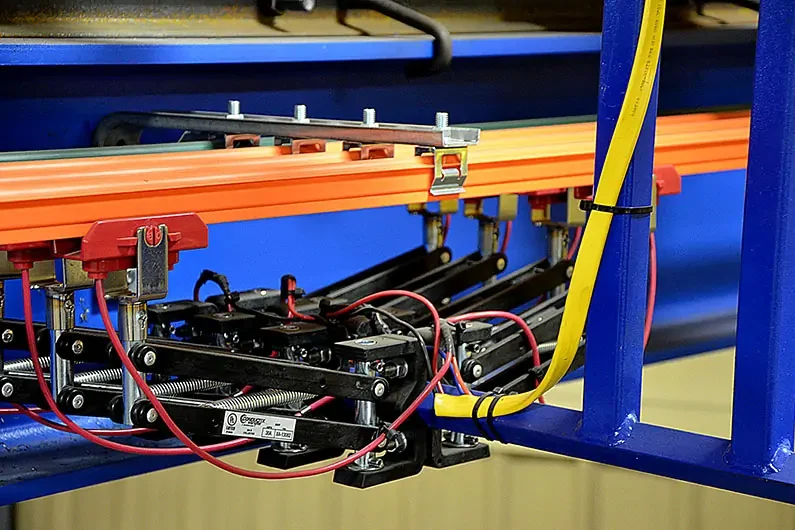

Electrical system

The electrical system is the heart of an EOT crane, the crane's nerve center. It powers the motor, controller, and safety devices. It's prone to problems due to vibration and environmental factors. Common problems and their solutions are listed below:

Contactor does not engage: If the crane does not respond when the start button is pressed, check the power supply, whether the fuse is blown, or whether the cam controller handle is in the zero position. You can use a multimeter to test the voltage, replace the fuse, or reset the controller to solve the problem.

Overcurrent relay trips: This usually indicates a ground fault in the cam controller. Check the contacts with a megohmmeter, polish any burned contacts, or replace the faulty part.

Motor does not rotate: If the contactor is closed but the motor does not run, check for loose brush connections, damaged speed control resistors, or worn rotor windings. Adjust the brushes, repair the resistors, or replace the motor as needed.

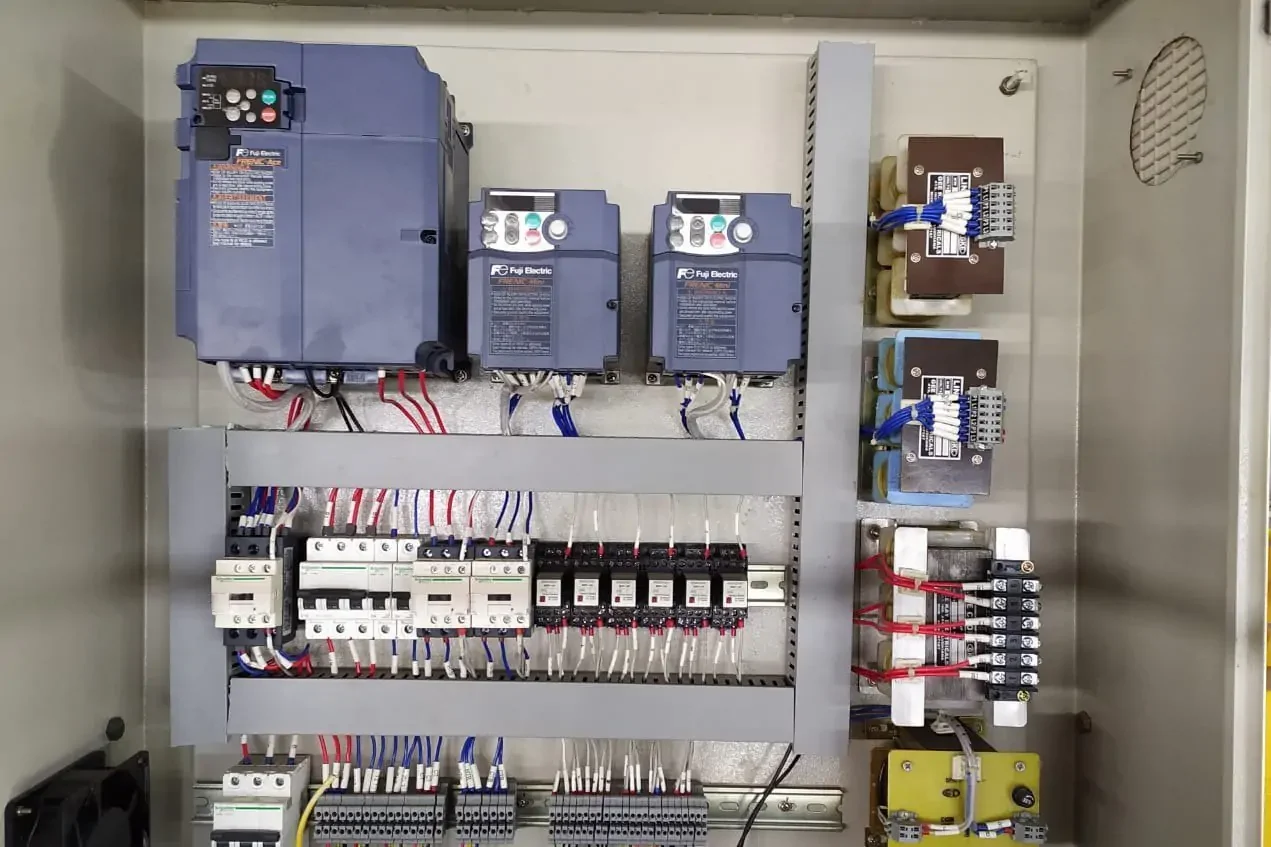

Control Panel

The control panel is the crane's brain, housing contactors, relays, and switches that manage all crane functions. During maintenance, ensure all switches and terminals are clearly labeled to facilitate troubleshooting.

Monthly inspection: Tighten loose terminals, confirm that the labels are consistent with the circuit diagram, and use a megohmmeter to check the insulation resistance between the terminals and the ground.

Cleaning: Dust and debris can cause short circuits. Use compressed air to clean internal components and ensure ventilation holes are clear.

Wire rope

The wire rope bears the main load of the heavy object, and its condition is directly related to safety.

Regular inspection: Check for wear, kinks, broken wires, etc. When the relevant standards are met, they need to be replaced in time.

Lubrication: Apply the manufacturer's recommended lubricant to reduce friction and prevent corrosion. Be careful not to over-lubricate to avoid attracting dust.

Accessory Inspection: Check the rope loops, pins, and hooks for cracks or elongation. Damaged hardware must be replaced immediately.

Drivetrain

In the transmission system, the gearbox enables the crane to move along the track. Its normal operation depends on proper lubrication and calibration. The coupling connects the motor and gearbox. Its condition will also affect the operation of the equipment. The maintenance of both requires simultaneous attention.

Oil Check: Make sure the lubricating oil reaches the minimum level marked on the gearbox. Drain and replace the lubricating oil according to the manufacturer's specifications.

Leak Check: Check for leaks around seals, drain plugs, or the oil filler cap. Replace worn seals to prevent lubricant loss.

Component wear inspection: Regularly open the gearbox inspection cover to check whether the gears have broken teeth or excessive clearance. Also, check the tightness and alignment of the coupling bolts. Replace damaged gears and worn couplings, and tighten loose keys.

Brakes

Brakes are critical to safety, and their failure could cause the load to swing or the crane to fail to stop.

Functional test: Check daily that the brakes engage smoothly and hold the load securely. If the crane wobbles when stopped or won't stop, check the brake pads for wear and replace them.

Air gap check: Ensure the gap between brake components meets the manufacturer's specifications. Clean the brake surface of debris to avoid friction loss.

Rectifier check: For electric brakes, verify that the rectifier is functioning properly. A faulty rectifier may cause braking delay.

EOT Crane Regular Maintenance Recommendations

| تكرار | Task |

| Daily | Check the wire rope/chain for wear, kinks, or damage. Test the brakes and limit switches. Check the gearbox oil level and lubricate moving parts. Watch for unusual noises during operation. |

| Weekly | Deep clean the brakes and inspect the rotor discs for wear. Check the runway track for alignment and debris. Tighten loose bolts on load-bearing components. Review the daily operator report and address any recurring issues. |

| Per Month | Check the control panel connections and insulation resistance. Check for frayed or exposed wires. Test safety devices such as overload relays and emergency stop buttons. |

| Quarterly | Replace the gearbox oil and check for metal particles. Check the bridge and rails for cracks or deformation. Lubricate the wire rope thoroughly. |

| Each Year | Perform overload load tests to verify lifting capacity. Inspect all structural welds and replace worn parts. Recertify safety devices and document all maintenance to comply with regulations. |

خاتمة

In short, EOT crane maintenance must be given high priority. Equipment maintenance should be preventive, with regular maintenance measures and strict adherence to standard operating procedures to minimize safety incidents during operation and ultimately extend the service life of the EOT crane.