A gantry crane is a kind of large lifting equipment widely used in the industrial field, which is characterized by strong carrying capacity, a wide operation range, and flexible operation. It is widely used in construction sites, port terminals, logistics warehouses and manufacturing workshops, and other outdoor operations. In this article, we will introduce the core components of the gantry crane, common types, and their diverse application scenarios in detail. I believe this article can provide you with valuable information to help you choose the right lifting program!

What is a Gantry Crane?

Gantry cranes, commonly known as gantry hoists, are heavy-duty lifting equipment utilising a distinctive portal frame support structure. They comprise a rigid, portal-shaped frame crane capable of traversing rails or wheels, coupled with a lifting trolley that moves along the beam. Unlike bridge cranes, gantry cranes offer exceptional mobility, enabling rapid vertical lifting, horizontal traversing, and regional transfer of heavy loads. Their flexibility, substantial load-bearing capacity, and minimal site requirements make them commonplace in modern open-air industrial and logistics operations.

They are primarily employed for handling and installation tasks in open storage yards, shipyards, power stations, harbours, and railway freight stations.

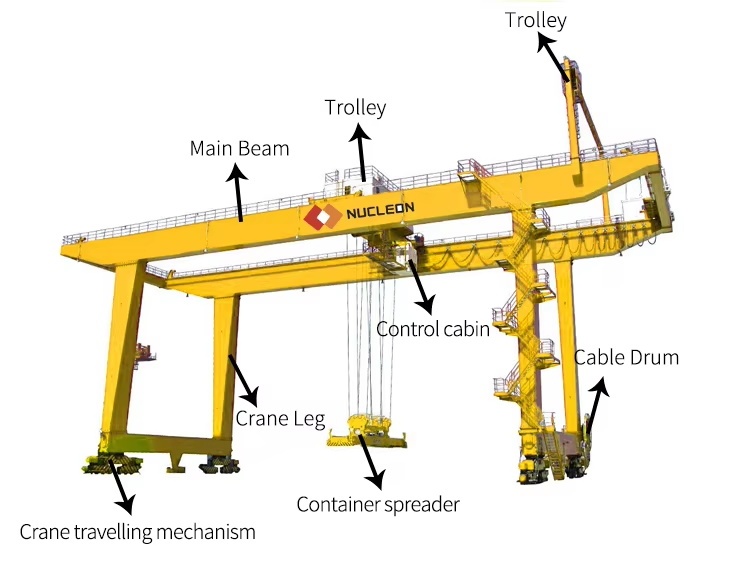

Gantry Crane Components

The gantry crane system mainly consists of a portal frame, a lifting mechanism, a traveling device, and other parts. The following are the functional characteristics of each component:

Gantry Crane Parts

- Main Beam: The horizontal structure that supports the load, with the option of single or double girder construction.

- Outriggers: Rigid legs that provide stability.

- Traveling Mechanism: Enables the crane to move along the tracks.

- Hoist: The lifting mechanism.

- Control System: Three control methods, including pendant control, remote control and cabin control.

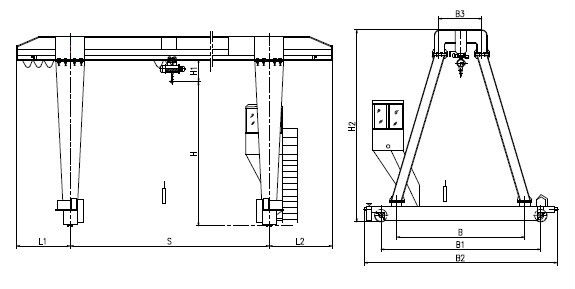

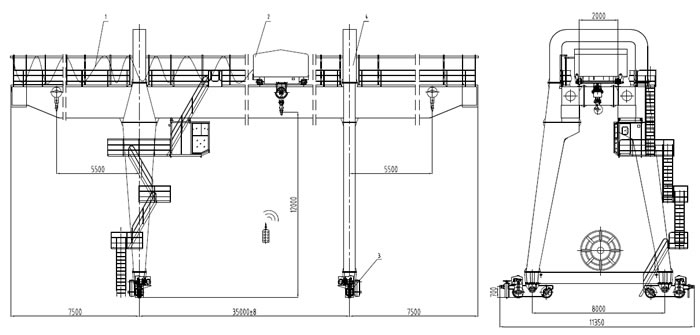

Gantry Crane Design

Single Girder Gantry Crane Design

Double Girder Gantry Crane Design

How does a Gantry Crane work?

Gantry cranes usually rely on lifting trolleys to realize vertical lifting and horizontal transportation of heavy loads. The operator sends commands through the control terminal, and the control system transmits the signals to the drive motor, thus accurately controlling the movements of the crane. The lifting trolley can be equipped with a variety of special lifting gears according to the actual needs, including standard hooks, electromagnetic suction cups, or grab devices, etc., in order to adapt to different material handling requirements.

Types Of Gantry Crane

Gantry cranes are versatile lifting solutions designed for a variety of industrial applications. Below is a detailed categorization of Gantry Cranes based on their mobility, construction, and specific applications, as well as their main features, lifting capacities, and uses.

Type Directory

- Classified By Gantry Structure

- Categorized By Main Girder Structure

- Classification By Main Beam Form

- Classification According To Mobility

- By Application

1. Classified By Gantry Structure

Full gantry crane

Symmetrical support legs on both sides, no suspension of the main beam, trolley running in the main span, and full coverage of the working area. High stability and load-bearing capacity, ideal for heavy-duty applications and large-span operations. Widely used in outdoor yards, harbor and container terminals, heavy manufacturing facilities, and other scenarios.

Semi Gantry Crane

One side is supported by an outrigger, the other side is supported by a runway, and the main beam is available in single and double-beam structures. The structural design is space-saving and suitable for both indoor and outdoor operations, often used as a supplement to bridge cranes, making it a cost-effective choice. Lifting capacity 1t ~ 50t, widely used in steel, forest products, intermodal transportation, biomass/pellet, concrete, and other industries.

2. Categorized By Main Girder Structure

Truss girder structure

Angle steel or I-beam welding molding, a structural form of space truss system, wind resistance is better, and nodes are connected using high-strength bolt connections or welding. Lightweight and low investment in the foundation. The lifting capacity is usually ≤50 tons, which is suitable for outdoor sandy wind, lower safety requirements, and a smaller lifting capacity for small load operations. Widely used in bridge construction, large-scale manufacturing, the aerospace industry, and other scenes.

Box beam structure

High-quality steel plate welding molding, closed box section design, and internal reinforcement plate. Overall rigidity, strong deformation resistance, high load carrying capacity, high safety factor, smooth and reliable operation, suitable for high-frequency, heavy-load operating environments. Lifting capacity to 1200 tons. Widely used in ports, shipbuilding, and other heavy industrial fields.

3. Classification By Main Beam Form

رافعة جسرية ذات عارضة واحدة

Simple structure, lightweight, economical and efficient, easy to install and maintain, suitable for light to medium-sized tasks, lifting capacity of 1 ton ~ 20 tons. Widely used in warehouses, small workshops, light manufacturing, and other lifting operations.

رافعة جسرية ذات عارضة مزدوجة

Double girder structure design, strong load carrying capacity, large span, better overall stability, and equipped with an advanced control system. Lifting capacity is usually 5 tons ~ 500 tons or more. Widely used in heavy industry, steel mills, shipyards, and other heavy-load operations.

A Frame Gantry Crane

Triangular frame design, enhanced stability, compact and space-saving, ideal for outdoor use. The lifting capacity is from 10 tons to 100 tons, widely used in construction sites, outdoor storage yards, power plants, and other scenes.

4. Classification According To Mobility

Fixed Gantry Crane

Fixed installation with high stability and load carrying capacity, suitable for performing repetitive tasks in a fixed position, lifting capacity is usually in the range of 1 ton ~ 500 tons. Widely used in manufacturing facilities, workshops, assembly lines, and other lifting and loading operations.

Mobile Gantry Cranes

Portable and flexible, it can be moved to different locations. Lifting capacity is usually 1 ton ~ 200 tons. Mainly used in construction sites, maintenance and repair work, temporary lifting operations, and other outdoor scenes.

According to different scenarios and needs, they are divided into rail-mounted gantry cranes and tire-type gantry cranes, and their specific features and applications are as follows:

RMG Gantry Cranes

Operate on fixed rails with high precision and stability, and automated operation options. Lifting capacity of 10 tons ~ 100 + tons, widely used in container yards, storage facilities, railroad freight terminals and other loading and unloading operations.

Rubber Tired Gantry Crane (RTG)

Equipped with rubber tires, the RTG is flexible and suitable for outdoor heavy-load operations. Lifting capacity of 20 tons ~ 100 tons or more, widely used in container terminals, intermodal facilities, prefabricated girder yards, and so on.

5. By Application

General manufacturing gantry crane

It usually adopts two structural forms of box-type and truss-type, and is used for the transportation and loading/unloading operations of various kinds of piece goods and bulk materials. Lifting capacity of 100 tons or less, the standard span range of 4 ~ 39 meters, can be customized according to specific needs. Ordinary gantry cranes have higher working class requirements when adopting the grab operation mode, which can meet the needs of frequent and heavy-duty operations.

Hydropower station gantry crane

Adopting a high-strength box-type beam structure and a double-track operation system, it is designed for hydropower projects, mainly used for gate lifting, opening and closing operations, and installation of hydro generator sets and other operations. The rated lifting capacity is 80-500 tons, and the working class is high, usually A5-A7.

Port Gantry Cranes

Designed for heavy-duty container handling, high lifting height and span, weather-resistant structure, lifting capacity of 30 tons ~ 100+ tons, widely used in container terminals, ports, and harbors, etc.

Quay Gantry Cranes

High lifting capacity and reach, designed for ship handling, robust and durable. Lifting capacity from 50 tons to 200+ tons, widely used in shipyards, ports, and harbors, rail-type.

Ship-to-shore Gantry Cranes

Huge lifting capacity and reach, designed for loading and unloading ships. Highly automated and efficient, lifting capacity from 50 tons to over 2,000 tons. Widely used in ports and harbors, shipyards, etc.

Workshop Gantry Cranes

Compact and lightweight, easy to operate and maintain, suitable for indoor lifting operations. Lifting capacity from 0.5 tons to 20 tons, widely used in workshops, warehouses, maintenance areas, and so on.

Small Portable Gantry Cranes

Lightweight and easy to assemble, flexible and movable, adjustable height and span, ideal for small lifting tasks. Lifting capacity of 0.5 tons to 10 tons, widely used in workshops, warehouses, maintenance and repair, stores, and so on.

Gantry Crane Price Analysis And Cost Impact Factors

The market price of gantry cranes depends on factors such as equipment specifications, lifting capacity, span size and lifting height, configuration, and features. The larger the tonnage, the longer the span, and the higher the lifting height, the equipment cost increases accordingly. And when choosing the main girder structure, the box girder is more costly than the truss girder. When choosing the drive system, frequency conversion control will also be more expensive than conventional control.

In terms of functional requirements, the degree of automation, special spreaders, and work grades are important considerations. Intelligent control systems, customized spreaders, and higher work grades will significantly increase the price of the equipment. In addition, additional factors such as installation and commissioning (complex sites increase installation costs), transportation costs (oversized equipment requires special transportation solutions), and after-sales service (extending the warranty period will increase the overall cost) will also affect the final expenditure. Users are advised to consider the performance of the equipment, the usage requirements, and the long-term operating costs when purchasing, and choose the most cost-effective solution.

| Lifting Capacity (tons) | Span (meters) | Price Range |

|---|---|---|

| 0.5~5 ton | 5-10 m | $4,600 – $38,000 |

| 5~20 ton | 8~20 m | $10,000 – $62,000 |

| 20~50 ton | 10~31.5 m | $62,000 – $150,000 |

| 50~200 ton | 10~31.5 m | $150,000 – $1,000,000 |

Looking for the best gantry crane for your facility? Contact our team for a free consultation and quotation within 24 hours.

10 Important Gantry Crane Maintenance Tips

Daily inspection of key components: Regularly check the wear and tear of wire ropes, hooks, and spreaders to ensure there are no cracks or deformations.

Functional test of safety devices: Confirm that safety devices such as limit switches, overload protection, etc., are working properly, and repair faults in time.

Track and wheel maintenance: Observe the flatness of the track and the wear and tear of the wheels to ensure that there is no error in alignment and to avoid running deviation.

Regular lubrication of moving parts: Lubricate critical parts such as bearings, gears, pulleys, etc. according to the manufacturer's requirements, using appropriate lubricants to avoid over-lubrication.

Structural integrity check: Regularly inspect main beams, outriggers, and other major structures, tighten bolted connections, and repair damaged anti-corrosion coatings.

Electrical System Maintenance: Check the condition of cable insulation, clean electrical control cabinets, test safety devices, and alarm systems.

Establishment of maintenance plan: Quarterly comprehensive inspections, annual overhauls and performance tests, record maintenance logs, and track equipment status.

Standardize Operating Behavior: Observe rated load limits, avoid sudden starts and stops, and stop use in bad weather.

Professional Maintenance Support: Regularly invite professional technicians for inspection, timely replacement of badly worn parts, and necessary upgrades.

Establishment of maintenance files: Record in detail the content of each maintenance, problems found, and treatment measures to provide data support for equipment management.

FAQ

Q1: What is the difference between a gantry crane and an overhead crane?

A1: A gantry crane has its own supporting legs and runs on ground rails or rubber tires, making it ideal for outdoor lifting operations such as in ports, shipyards, and construction sites.

An overhead crane, on the other hand, is installed on building columns or beams and is mainly used indoors.

Q2: How much does a gantry crane cost?

A2: The gantry crane price varies depending on lifting capacity, span, height, and design type.

For reference, a 5-ton gantry crane typically costs around $10,000 – $25,000, while a 100-ton heavy-duty gantry crane can exceed $150,000.

For the full gantry crane price list, please refer to the table above or contact us for a customized quote.

Q3: What types of gantry cranes are available?

A3: There are several common types of gantry cranes, including:

Single girder gantry crane – economical for light-duty lifting (1–20 tons).

Double girder gantry crane – heavy-duty structure for industrial use (up to 500+ tons).

Portable gantry crane – mobile, adjustable, easy to assemble.

Rubber-tired gantry crane (RTG) and rail-mounted gantry crane (RMG) – ideal for container yards and terminals.

خاتمة

To summarize, gantry cranes are a diverse type of lifting solution with high load capacity and versatility to meet the application needs of different industries. Whether you are looking to purchase a standard model or need a customized solution, Nucleon Crane can provide you with a one-stop service from selection to installation. Contact us today for more information and a quote on gantry cranes, and let us help you find the right lifting solution.