Bridge cranes are indispensable in modern industrial systems . Whether transferring car bodies in automotive factories, loading and unloading containers at logistics hubs, or even positioning parts in precision workshops, the performance of bridge cranes directly determines the efficiency and safety of production operations . For buyers, choosing the right crane manufacturer not only ensures more reliable product quality but also provides comprehensive product sales and service. This article provides information on the world's top ten bridge crane manufacturers , providing a reference for purchasing companies.

Top 10 manufacturers

Konecranes

As a global leader in the crane industry, Konecranes has always taken technological innovation and global services as its core advantages since its establishment in 1910, and has occupied a significant market share in the fields of ports, industry, mining, etc. Its outstanding advantages are reflected in:

Full-scenario solution capabilities : We can provide a full range of bridge cranes from light to ultra-heavy, which can adapt to the needs of multiple industries such as automobile manufacturing, steel metallurgy, nuclear power and energy. For example, we customize high-precision assembly line cranes for BMW automobile factories to achieve precise docking of car body parts.

Leading Intelligent Technology : The company's intelligent monitoring system collects equipment operating data in real time, predicts potential failures through data analysis, and significantly reduces downtime. Its unmanned crane solution has been deployed in multiple international logistics hubs, achieving full automation of material handling.

Global service network : With production bases and service centers in dozens of countries around the world, we can provide customers with rapid spare parts supply and on-site repair services. After-sales response time does not exceed 24 hours, ensuring the continuous and stable operation of equipment.

Demag Cranes

Demag is a German crane machinery brand with nearly 200 years of history. It is well-known for its exquisite manufacturing technology and reliable product quality. It is highly competitive in the field of medium and heavy-duty bridge cranes:

Structural design and durability : Made of high-strength steel and precision welding technology, the bridge crane has a stable structure, excellent fatigue resistance, and a service life far exceeding the industry average. It is suitable for high-intensity operation scenarios such as heavy machinery manufacturing and wind turbine assembly.

Outstanding customization capabilities : Equipment can be customized according to customers' special needs. For example, the large-tonnage wind power crane developed for Siemens wind power projects can achieve efficient lifting and precise positioning of wind turbine blades.

Technological inheritance and innovation : While maintaining traditional manufacturing advantages, we continue to invest in the research and development of intelligent technologies. The variable frequency speed regulation system we launched can significantly reduce equipment energy consumption, which is in line with global environmental protection trends and is favored by many green production companies.

ABUS

Since its establishment in 1910 , ABUS has focused on the research, development, and manufacturing of cranes and electric hoists. Known for its " high precision and high reliability ," it holds a leading market share in the global small and medium-sized bridge crane market.

Precision control and ease of operation : The bridge cranes produced by our company have high operating accuracy and can meet the precise handling needs of light and small materials such as electronic components and precision molds. For example, the clean room cranes provided to Samsung Electronics factories are adapted to the dust-free production environment of semiconductor chips.

Rich product range : Covering a variety of types of bridge cranes such as single-girder and double-girder cranes, which can be flexibly selected according to the customer's workshop space and load-bearing requirements. At the same time, a variety of configuration options are provided to meet the personalized needs of different industries.

Quality and safety assurance : All products have passed the German TÜV certification and international safety standards, and are equipped with comprehensive safety protection devices to ensure the safety of personnel and equipment during operation. They have a very high reputation in the global precision manufacturing industry.

EMH

As a major brand in the North American bridge crane market, EMH has been outstanding in the medium and heavy-duty customized crane market since its establishment in 1988, with customized services and fast delivery as its core competitiveness:

Quick customized response : Relying on advanced automated production bases, we can quickly respond to customers' special needs. For example, the low-headroom crane customized for Tesla's battery factory can achieve efficient material handling within the limited workshop height and meet the special space requirements of battery production.

Delivery cycle advantage : By optimizing production processes and modular component design, the delivery cycle of customized equipment is significantly shorter than the industry average. Expedited services can be provided for urgent projects to help customers shorten project construction cycles.

Regional market adaptation : With an in-depth understanding of North American market safety regulations and industry demands, our products fully comply with local standards and can be put into use without additional adaptation. We are the preferred brand for North American local companies and North American factories of multinational corporations.

Gorbel

Gorbel Since its establishment in 1977, the company has been recognized by automotive parts and electronics manufacturers for its ergonomic design and lightweight products, occupying an important position in the field of light bridge cranes and intelligent lifting equipment.

Lightweight and space adaptability : Made of high-strength alloy, the bridge crane has a light weight and low load-bearing requirements for the factory building. It is suitable for the renovation of old factories or modern workshops with limited space. For example, the light assembly line crane provided for Apple mobile phone supply chain factories can achieve efficient material flow in a narrow space.

Intelligent lifting technology : The intelligent lifting device developed by us significantly reduces the intensity of manual handling through gravity sensing technology. It has high operating precision and can avoid damage to vulnerable parts during handling. It is widely used in the production of mobile phone screens and precision electronic components.

Localized service capabilities : With production bases and service centers in China, Europe and other regions, we can quickly respond to regional market needs and provide one-stop services such as equipment installation, operation training, maintenance, etc., providing an excellent after-sales experience.

Nucleon

As an innovative leader in China's lifting machinery industry, Nucleon is rapidly becoming a global premium manufacturer by leveraging its expertise in intelligence, energy conservation, and specialized applications. Its core strengths include:

Breakthroughs in intelligence and unmanned operations : The independently developed unmanned bridge crane integrates laser positioning, visual recognition, and 5G remote control technologies, enabling unmanned operation of the entire process from " automatic grasping - path planning - precise stacking " . It has been successfully deployed in JD Asia No. 1 Smart Logistics Park, significantly improving warehousing and handling efficiency and reducing labor costs.

Customization capabilities for special industries : For the nuclear power sector, we have launched dedicated cranes that use radiation-proof materials and dual safety braking systems. These cranes have passed international nuclear power safety certification and have served the overseas nuclear power projects of China General Nuclear Power Group and Electricité de France. For the food and pharmaceutical industries, we have developed sanitary stainless steel cranes with a polished surface that can withstand high-temperature disinfection and are suitable for the sterile production workshops of Mengniu and Pfizer Pharmaceuticals.

Cost-effectiveness and service advantages : Leveraging China's comprehensive supply chain system and manufacturing capabilities, the prices of intelligent cranes of the same specifications are more competitive than those of European and American brands. With service outlets established in multiple regions around the world, we provide timely technical support and after-sales maintenance, making them a cost-effective choice for an increasing number of companies.

Wei Hua

As a leading enterprise in China's lifting machinery industry, Weihua has occupied a significant share of the global low-end and mid-range markets since its establishment in 1988 , relying on large-scale production and full product coverage, while gradually breaking into the high-end market:

Full product range : covers general-purpose bridge cranes, metallurgical cranes, explosion-proof cranes and other series, with a rich variety of models to meet the diverse needs from small and medium-sized factories to large-scale infrastructure projects, such as the large-span bridge component handling cranes provided for China's high-speed rail construction projects.

Scale and cost advantages : Relying on multiple large-scale production bases, we can achieve large-scale manufacturing of equipment, effectively reducing production costs. The price of general-purpose bridge cranes of the same specifications is significantly competitive, while maintaining stable product quality, which is favored by many small and medium-sized enterprises around the world.

Global market expansion : Products have been exported to more than 170 countries and regions around the world. We have established a complete sales and service network in Southeast Asia, Africa and other regions, which can quickly respond to local customer needs and gradually enhance our brand influence in the international market.

Kito Corporation

Since its establishment in 1932 , Guitou has focused on the research, development, and manufacturing of electric hoists and small and medium-sized bridge cranes. Known for its durability and high precision , it enjoys an excellent reputation in the global light lifting equipment market.

Outstanding product durability : Made of high-quality steel and precision transmission components, the bridge cranes and electric hoists produced have a long service life and a low failure rate. They are suitable for industries with high requirements for equipment stability, such as electronics manufacturing and food processing. For example, the assembly line cranes provided to Toyota auto parts factories have long-term stable operation without trouble.

Precision control and operation : The equipment has high operating accuracy and flexible adjustment of lifting and running speed, which can achieve smooth material handling and avoid material damage caused by operating errors. It is widely used in the precision manufacturing industry.

Global Layout : With production bases and sales outlets in Asia, North America, and Europe, we can provide adapted products and services to customers in different regions. At the same time, we optimize equipment design according to local market demands to enhance product competitiveness.

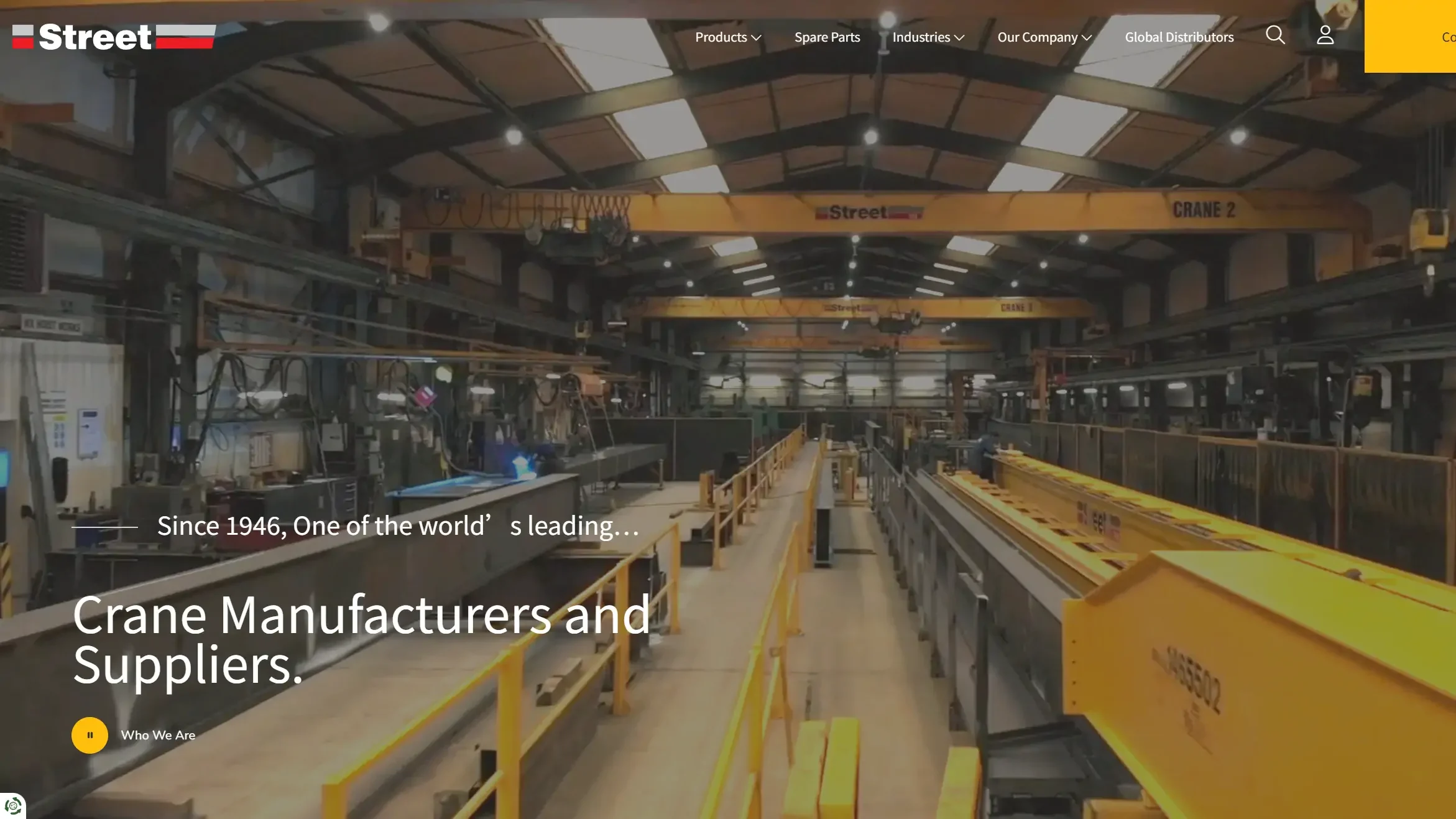

Street Crane

Since its establishment in 1946 , Street Crane Company has specialized in heavy-duty industrial cranes. With its core strengths of large tonnage and resistance to harsh environments, it has gained significant influence in the steel and mining industries.

Large tonnage and high-intensity operation capability : We can produce super-large bridge cranes with a maximum lifting capacity of hundreds of tons. They are made of high-strength alloy steel and reinforced structural design, and can operate continuously and stably in high-temperature and dusty steel metallurgical workshops or mining environments. For example, the special mining cranes customized for Rio Tinto Mining can achieve efficient handling of ore.

Comprehensive safety design : Equipped with multiple safety protection systems, including overload protection, emergency braking, wind speed warning, etc., it also has a remote fault diagnosis function that can monitor the equipment's operating status in real time, warn of potential risks in advance, and ensure operational safety in high-intensity working environments.

Rich industry experience : With decades of experience in the heavy industry and a deep understanding of the operational characteristics of industries such as steel and mining, we can provide customers with equipment and solutions that better meet their actual needs, and are deeply trusted by large international industrial companies.

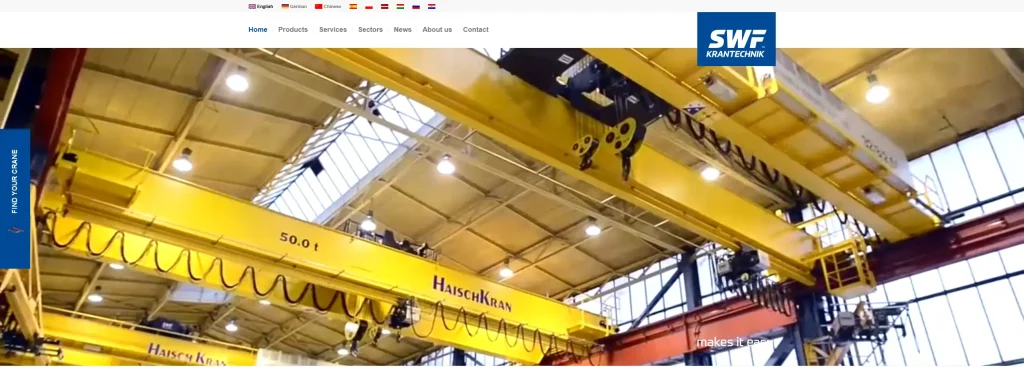

SWF Krantechnik

As a well-known German lifting equipment brand, SWF specializes in the manufacture of small and medium-sized bridge cranes and electric hoists. Characterized by " high precision and high cost performance " , it is widely used in the global precision manufacturing industry:

Precision electric hoist technology : The independently developed electric hoist transmission system has precise characteristics, high positioning accuracy, and a wide range of lifting speed adjustment. It is suitable for the precise handling of light and small materials such as electronic components and precision molds. For example, the electric hoist crane provided for Bosch Precision Instrument Factory realizes the efficient assembly of precision components.

Explosion-proof and adaptable to special environments : The explosion-proof bridge crane launched by the company adopts flameproof electrical components and sealed structure design, which can operate safely in flammable and explosive environments such as chemical, oil and gas. It has served the production workshops of international chemical companies such as BASF and Shell.

Flexible customization and fast delivery : Equipment parameters can be flexibly adjusted according to the customer's workshop layout and operational requirements. At the same time, fast delivery is achieved by optimizing the production process, helping customers shorten the equipment procurement cycle and put it into production as soon as possible.

Conclusion

the global bridge crane market , each with its own strengths. Buyers should carefully consider their needs to select the most cost-effective bridge crane. If you are interested in a bridge crane, please contact Nucleon. Our professional engineers will provide you with the most customized services that are tailored to your needs.